Positioning pin mechanism, substrate transfer device and substrate transfer method

A technology of positioning pins and substrates, applied in transportation and packaging, conveyor objects, furnaces, etc., can solve the problems of complex movements, abnormal quality and high cost, and achieve the effect of reducing costs, avoiding abnormal quality and reducing design costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further illustrate the technical means adopted by the present invention and its effects, a detailed description is given below in conjunction with the preferred embodiments of the present invention and the accompanying drawings.

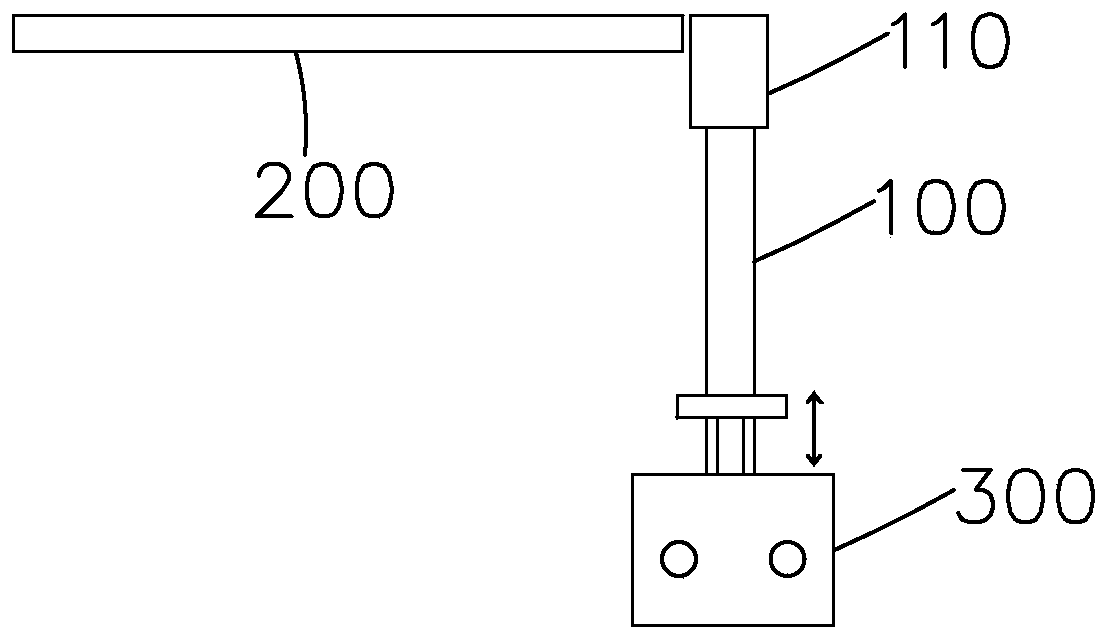

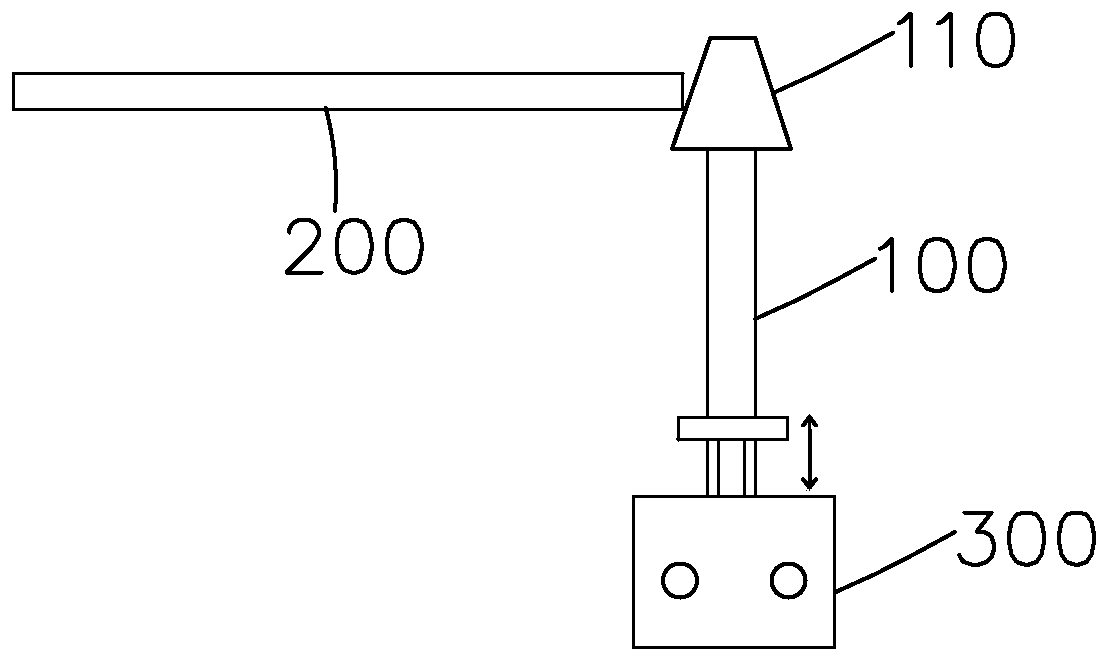

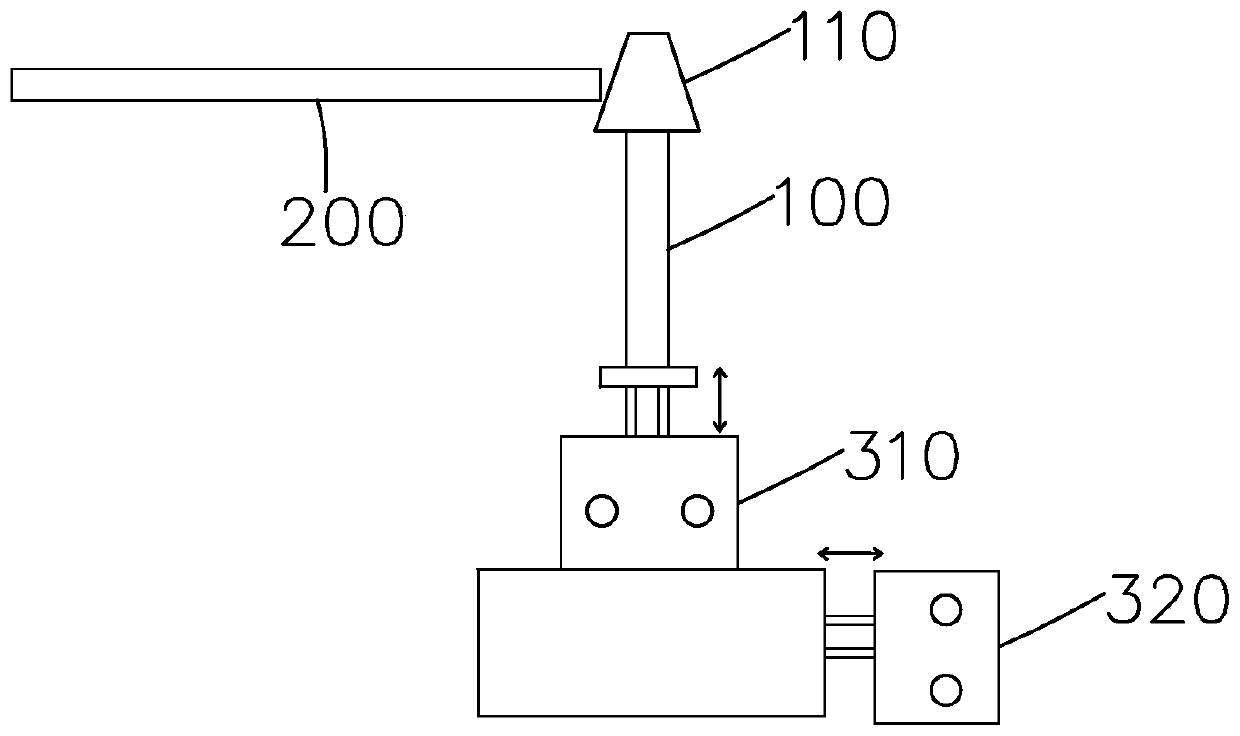

[0037] see Figure 4 , the present invention first provides a positioning pin mechanism, including a positioning pin 20 and a cylinder 10 that drives the positioning pin 20 to move;

[0038] The cylinder 10 is inclined, and includes an inclined cylinder 11 and a piston rod 12 telescopically arranged in the cylinder 11, so that the piston rod 12 is inclined with the cylinder 11;

[0039] The positioning pin 20 is in a bent type, including a vertical rod 21 and an inclined rod 22; the vertical rod 21 is arranged vertically, and the top of the vertical rod 21 is provided with a positioning contact block 23, and the vertical rod 21 The lower end is connected with the top end of the inclined rod 22 , the lower end of the inclined rod 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com