Activating solution before chemical nickel plating based on ruthenium system and preparation method of activating solution

An electroless nickel plating and activation solution technology, which is applied in the field of activation solution, can solve the problems of loose catalytic layer, peeling, missing plating, etc., and achieve the effects of excellent coating adhesion, abnormal quality and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

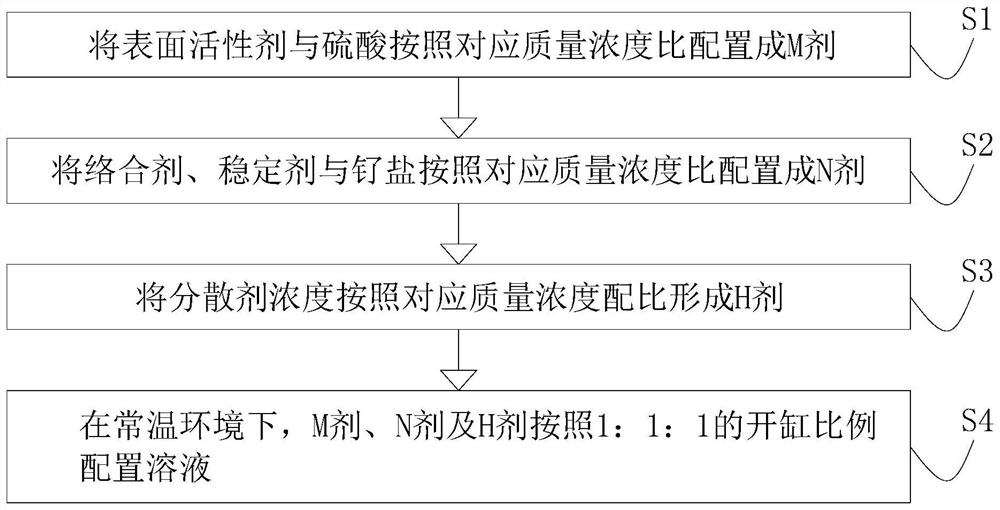

[0059] Such as figure 1 As shown, according to another embodiment of the present invention, the preparation method of the activation solution before the electroless nickel plating based on the ruthenium system comprises the following specific steps:

[0060] S1, surfactant and sulfuric acid are configured into M agent according to the corresponding mass concentration ratio;

[0061] S2, configuring the complexing agent, the stabilizer and the ruthenium salt into N agent according to the corresponding mass concentration ratio;

[0062] S3, the concentration of the dispersant is formulated according to the corresponding mass concentration ratio to form H agent;

[0063] S4. Under normal temperature environment, M agent, N agent and H agent are prepared according to the opening ratio of 1:1:1.

[0064] In one embodiment, the M dose, N dose and H dose are all opened by 10% per liter of cylinder.

Embodiment 1

[0066] In terms of mass concentration per liter:

[0067] Ruthenium salt: 150-250mg / L

[0068] Concentrated sulfuric acid: 10-20g / L

[0069] Sulfamic acid: 120-300mg / L

[0070] N-Nitrosophenylamine: 40-100mg / L

[0071] Potassium thiocyanate: 5-15mg / L

[0072] Alum sulfate: 5-15mg / L

[0073] Alkyl glucoside: 20-40mg / L

[0074] Polyazaheterocyclic ammonium salt: 30-50mg / L.

Embodiment 1

[0097] According to the results obtained in Example 1, surface treatment with line width and line spacing below 2 mil / 2 mil will not cause seepage or missing plating after nickel plating, and after 5MTO, the tolerance of copper ions is higher than 150ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com