Low-temperature nickel plating solution, nickel plating technology, flexible nickel plating layer and flexible printed circuit board

A technology for flexible circuit substrates and nickel plating solution, which is applied to printed circuit components, secondary treatment of printed circuits, metal pattern materials, etc., and can solve missing plating, color difference, large pollution, too thick or too thin nickel plating, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present embodiment provides a kind of low-temperature nickel-plating liquid, and the component that comprises and content are as follows:

[0024] Nickel sulfate: Ni 2+ The content is calculated as 5.5g / L;

[0025] Sodium hypophosphite: 30g / L;

[0026] Glycine: 5g / L;

[0027] Lactic acid: 15g / L;

[0028] Malic acid: 10g / L;

[0029] Potassium iodide: 0.01g / L;

[0030] Thiourea: 0.003g / L;

[0031] Coumarin: 0.02g / L;

[0032] Acetaldehyde: 0.005g / L;

[0033] The rest is deionized water.

[0034] Wherein, sodium hypophosphite is used as reducing agent, glycine, lactic acid, and malic acid are used as complexing agent, potassium iodide is used as stabilizer, thiourea is used as accelerator, and coumarin and acetaldehyde are used as flexible additives.

[0035] The reducing agent of the present invention can be selected from conventional reducing agents used in the existing electroless nickel plating solution, including one or more of hypophosphite, borohydride, ...

Embodiment 2

[0050] The difference from Example 1 is that the content of the flexible additive in the above-mentioned low-temperature nickel plating solution is changed to 0.04g / L.

[0051] Refer to Example 1 for the low-temperature nickel plating process, and obtain a flexible printed circuit board B after the nickel plating is completed.

Embodiment 3

[0053] The difference from Example 1 is that the content of the flexible additive in the above-mentioned low-temperature nickel plating solution is changed to 0.08g / L.

[0054] Refer to Example 1 for the low-temperature nickel plating process, and obtain a flexible printed circuit board C after nickel plating is completed.

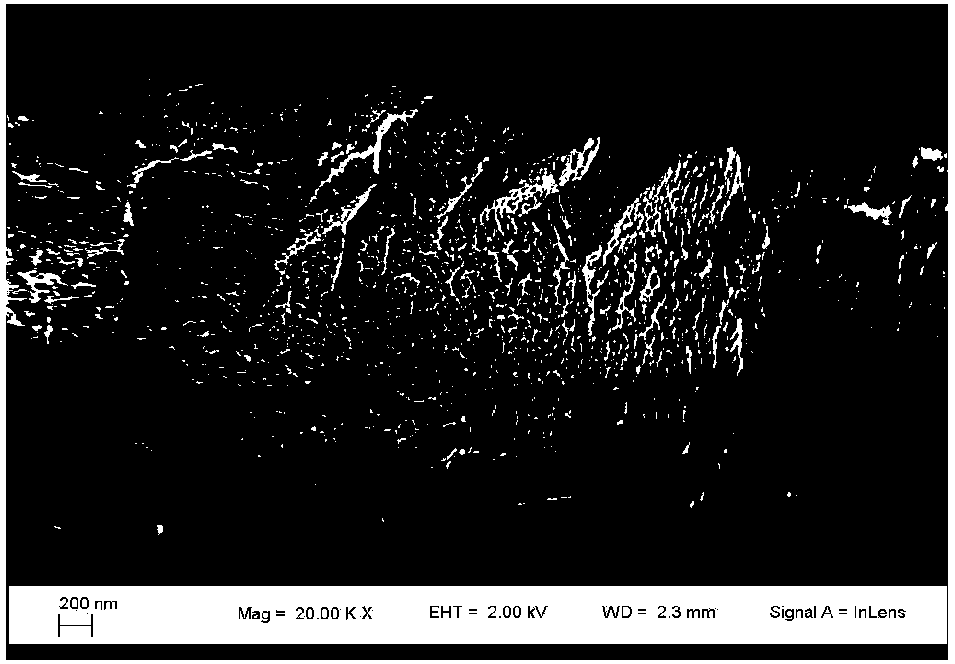

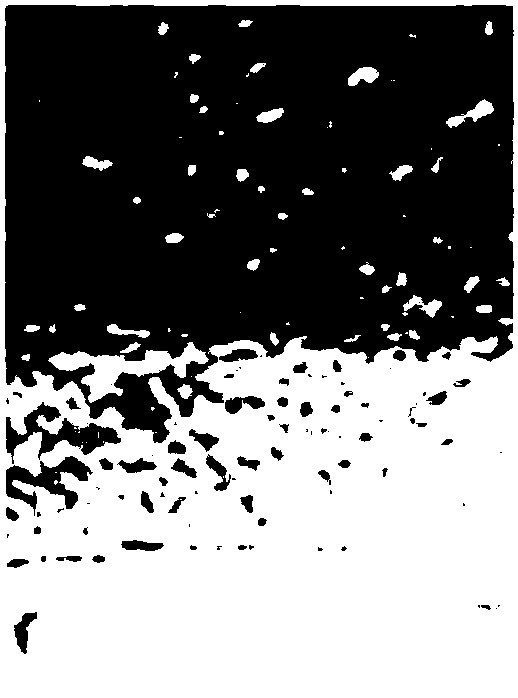

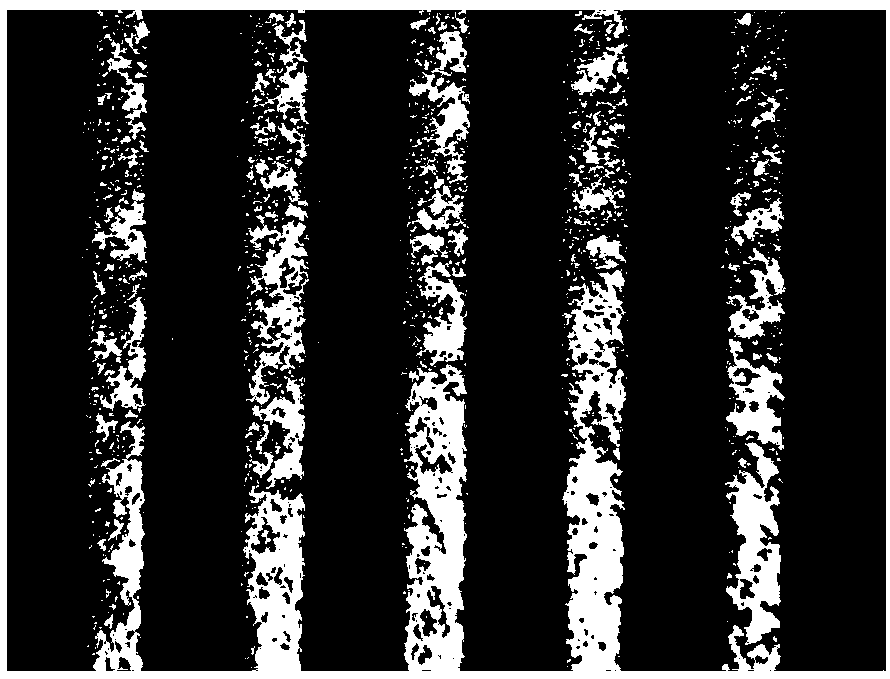

[0055] The columnar structure of the nickel-plated layer on the flexible printed circuit board A, B, C in embodiment 1-3 is compared, and the result is as follows Figure 7 shown.

[0056] The flexible printed circuit board A, B, C in embodiment 1-3 is carried out the result of MIT deflection test as following table:

[0057] Table 2

[0058] Test items

[0059] As can be seen from Table 2, the resistance value of the original copper material is very large after 1414 times of bending, that is, the crack is obvious and the flexibility is relatively poor; and the original copper material is processed through the low temperature nickel plating sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com