A kind of preparation method containing molybdate radical solution

A molybdate and solution technology, applied in chemical instruments and methods, molybdenum compounds, inorganic chemistry, etc., can solve the problems of low pulse laser ablation efficiency and difficulty in mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

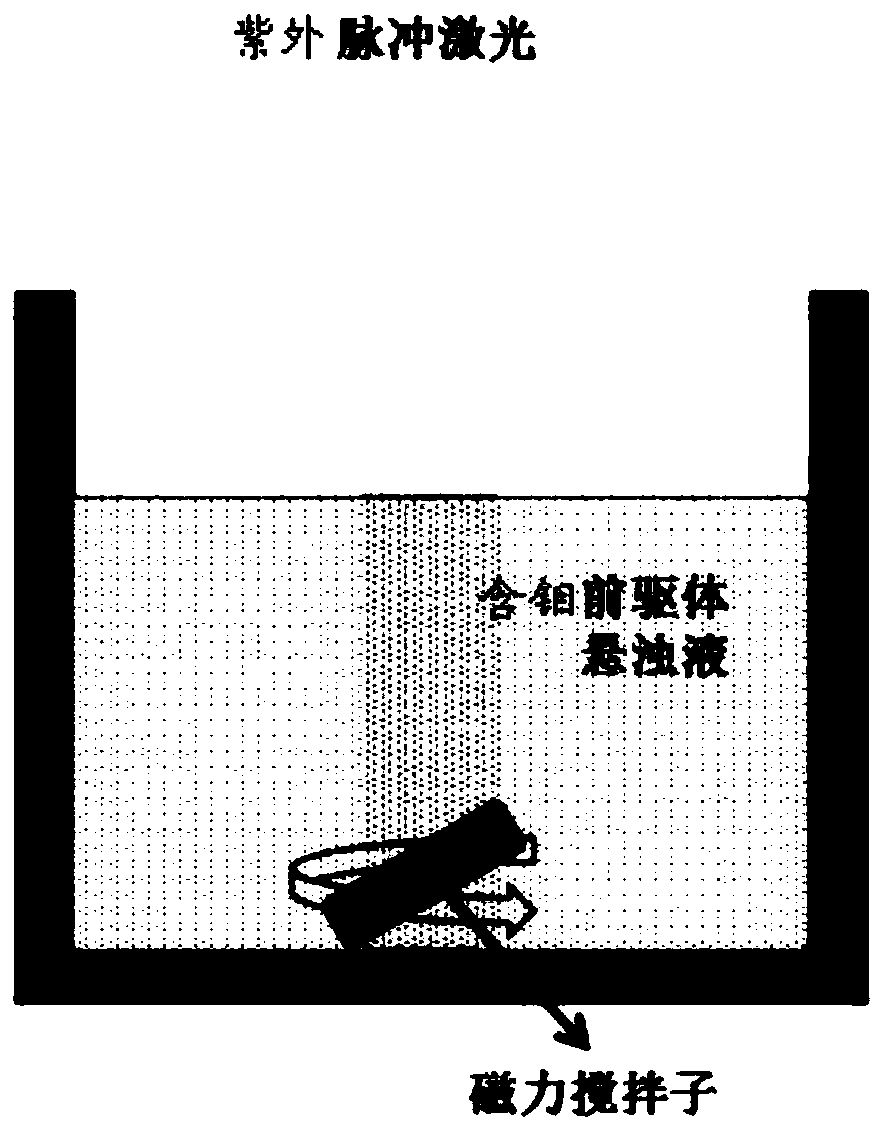

[0022] The invention provides a kind of preparation method containing molybdate radical solution, comprises the following steps:

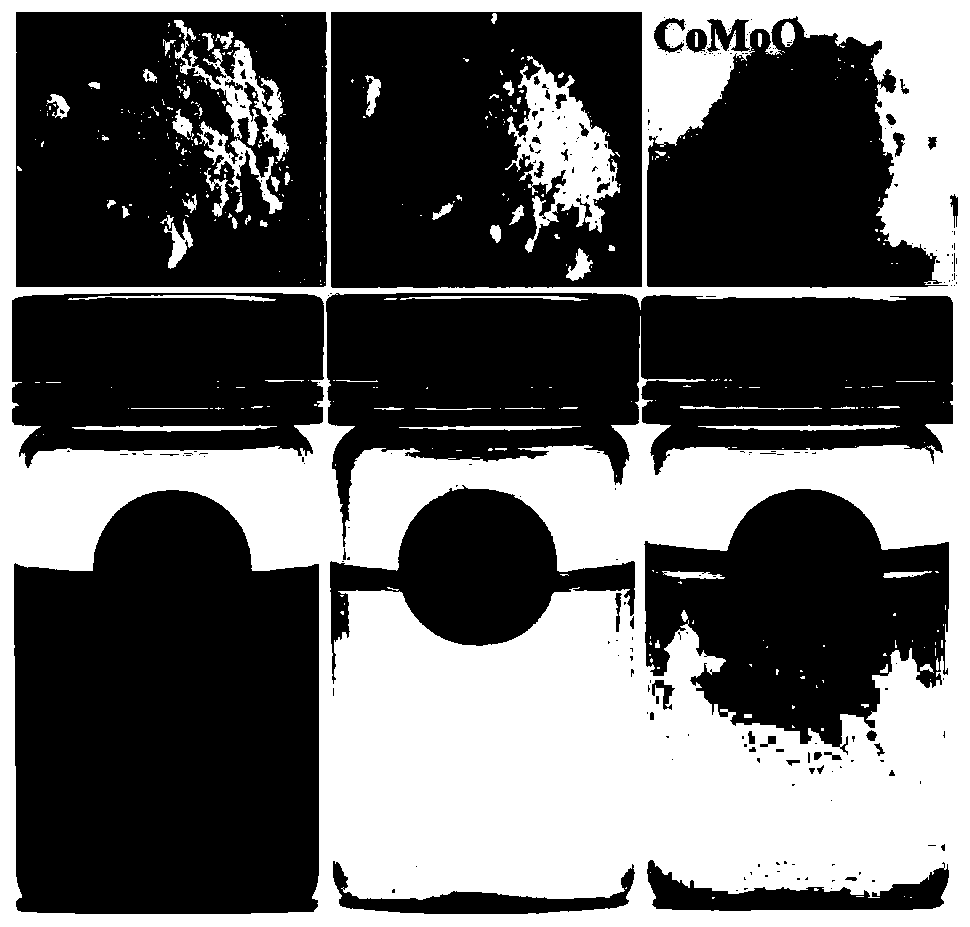

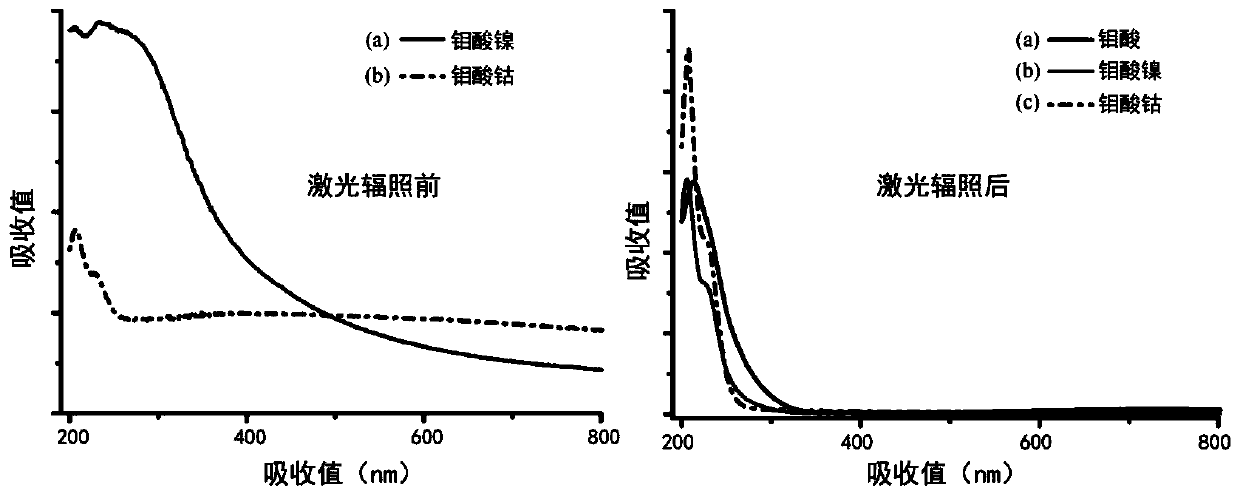

[0023] Molybdate-containing suspensions are provided, and the molybdate-containing radicals are derived from molybdic acid, cobalt molybdate or nickel molybdate;

[0024] Under stirring conditions, irradiate the molybdate-containing suspension with an ultraviolet pulse laser to obtain a molybdate-containing solution, the wavelength of the ultraviolet pulse laser irradiation is 355nm, the pulse width is 5~17ns, and the pulse frequency is (0 ,20] Hz.

[0025] The invention provides a molybdate-containing suspension, and the molybdate-containing molybdate is molybdic acid, cobalt molybdate or nickel molybdate. In the present invention, the concentration of the molybdate-containing suspension is preferably 0.01-10 g / L, more preferably 3-4 g / L.

[0026] In the present invention, when the molybdate-containing molybdate is preferably molybdic acid, the ...

Embodiment 1

[0042] The molybdic acid (H 2 MoO 4 ) suspension (the liquid in the suspension is deionized water, 18MΩ / cm), adjust the laser parameters at 20Hz pulse frequency, 60mJ single pulse energy range, the whole irradiation process is assisted by continuous magnetic stirring, stirring speed 500rpm, Observe the color and state changes of the dispersion liquid; after 30 minutes, when the powder particles in the suspension solution completely disappear, the aqueous molybdic acid solution can be obtained.

Embodiment 2

[0044] The molybdic acid (H 2 MoO 4 ) suspension (the liquid in the suspension is ethanol), adjust the laser parameters in the 20Hz pulse frequency, 30mJ single pulse energy range, the whole irradiation process is assisted by continuous magnetic stirring, the stirring speed is 500rpm, observe the color and state of the dispersion Change; after 50 minutes, the ethanol solution of molybdic acid can be obtained after the powder particles in the suspension solution completely disappear.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com