Countersunk head cross-shaped self-drilling screw and preparation technology thereof

A technology of drilling tail screw and cross, which is applied in the field of countersunk head cross drilling screw and its preparation technology, which can solve the problems of reducing connection strength and connection life, poor sealing performance, and easy corrosion, so as to ensure stable working performance and improve service life , Strong anti-rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

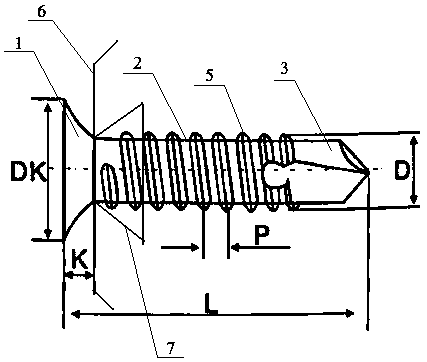

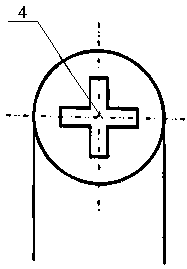

[0036] Such as figure 1 and figure 2 A countersunk head cross-drilling screw shown includes a pan head 1, a screw rod 2, a drill tail 3, a steel sheet 6 and a waterproof gasket 7, and one end of the screw rod 2 is fixedly connected to the pan head 1, and the The other end of the screw 2 is fixedly connected with the drill tail 3, the pan head 1 adopts a cylindrical hexagonal or circular countersunk structure, the upper surface of the pan head 1 is provided with a cross-shaped mouth 4, and the pan head 1 A steel sheet 6 is installed below, and a through hole is provided on the steel sheet 6, and the through hole is coaxially matched with the screw rod 2, and the waterproof pad 7 is provided with a shaft hole, and the upper end of the waterproof pad 7 is connected to the steel sheet 6. The lower end is matched, and the shaft hole is coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com