Automatic butted pipe joint device

An automatic docking and pipe joint technology, applied in the direction of pipe/pipe joint/pipe fitting, valve device, connection with fluid cut-off device, etc., to achieve the effect of high degree of automation, improved accuracy and small pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

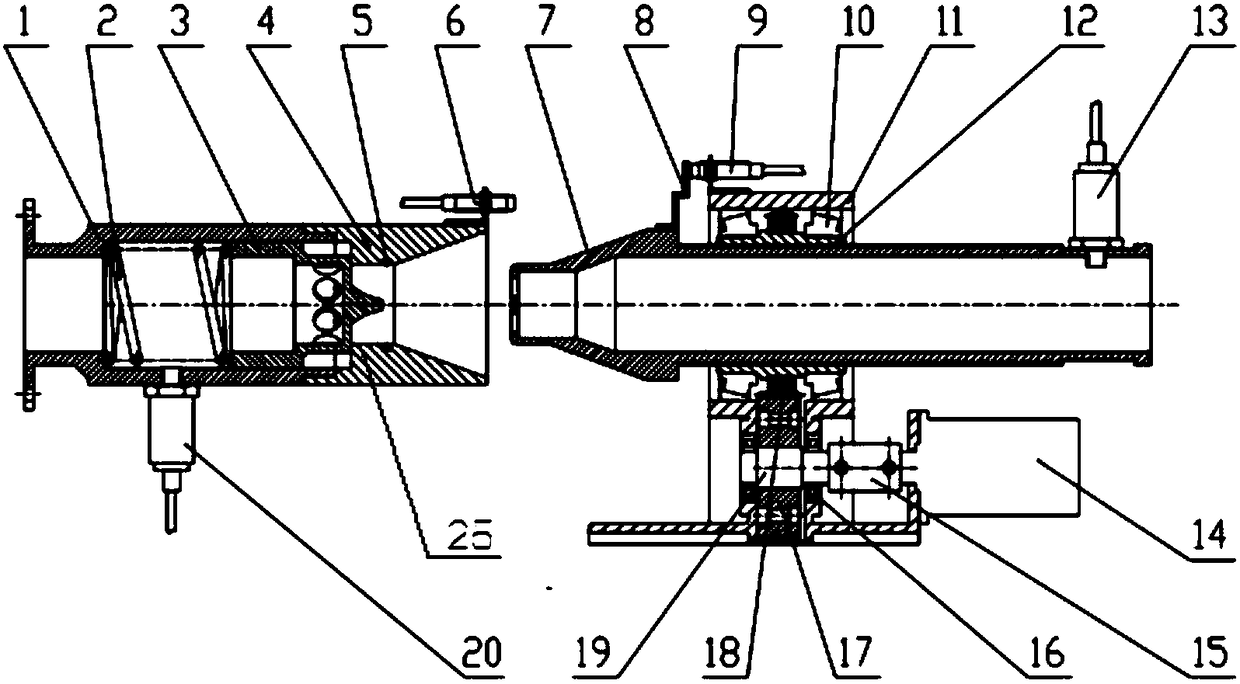

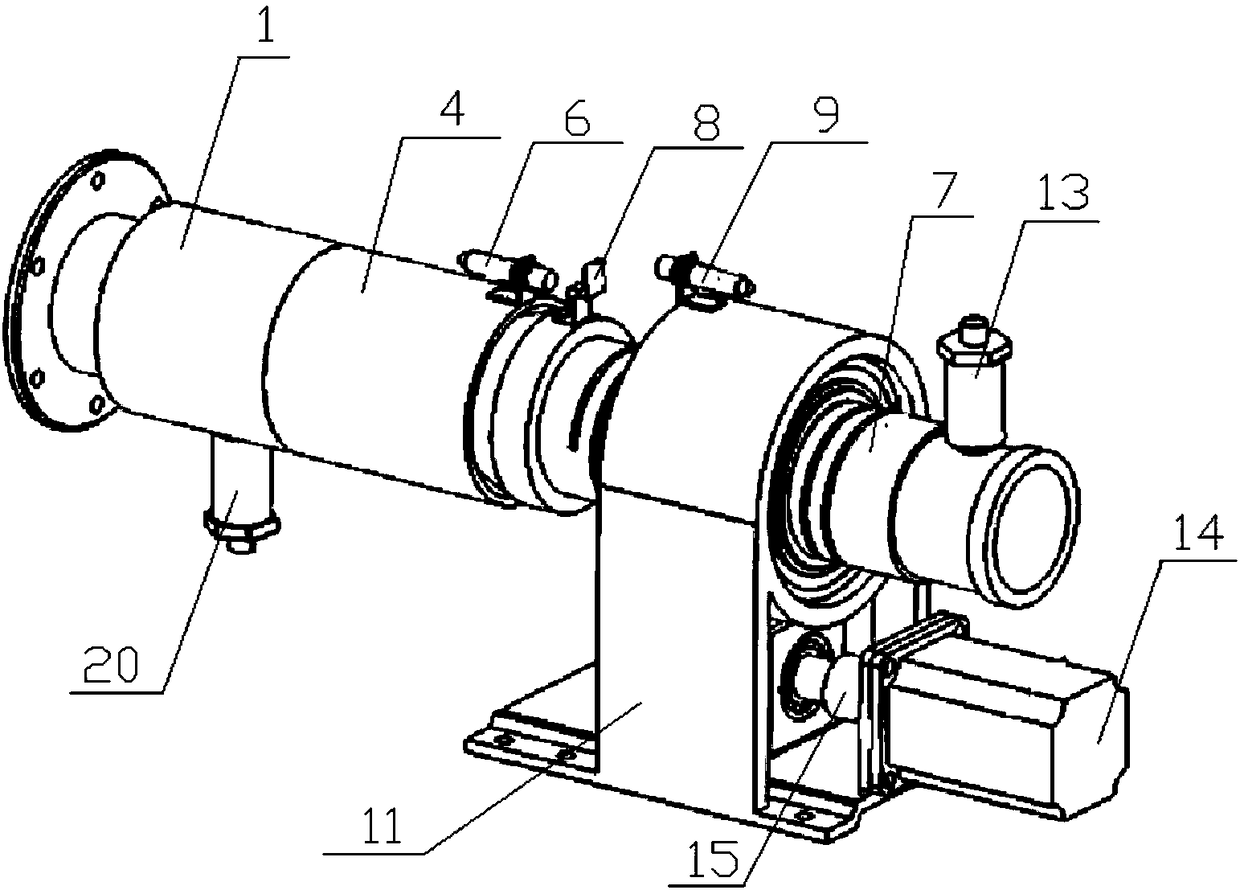

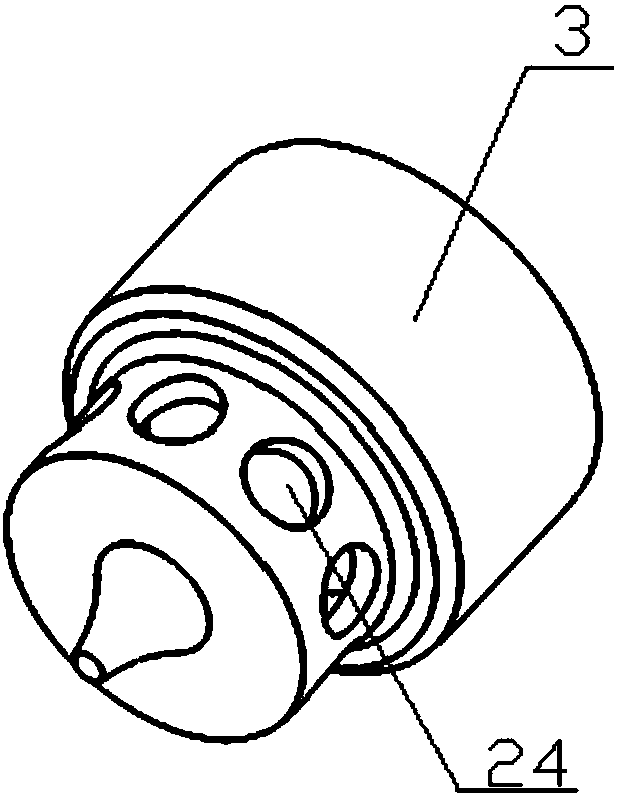

[0031] A pipe joint device for automatic docking of the present invention, such as figure 1 and figure 2 As shown, it includes a fixed sleeve 1 and a tapered guide sleeve 4 connected by threads, the tapered guide sleeve 4 is butted with a tapered butt joint 7, and the outside of the tapered butt joint 7 is threaded with a nut 12 to form a For the screw pair, the nut 12 is fixed. When the nut 12 rotates, the conical butt joint 7 can be driven to move in the axial direction. The nut 12 is externally connected with the driven gear 18, and the nut 12 is located at both ends of the driven gear 18 and is also sleeved with conical rollers. The sub-bearing 10, the tapered roller bearing 10 is connected with the base 11, and also includes a driving mechanism, the driving mechanism is connected to the gear shaft 19 through the coupling 15, the gear s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com