A loading device suitable for high and low temperature cycle test chambers and ct scanners

A technology of high and low temperature cycle and loading equipment, which is applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, scientific instruments, etc., and can solve the problem that oil hydraulic jacks cannot apply to high and low temperature freeze-thaw cycle engineering conditions, uniaxial compression instrument Unable to load real-time CT scans, unable to apply to ultra-high temperature and low temperature working conditions, etc., to achieve the effects of flexible and convenient testing, convenient production and operation, and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

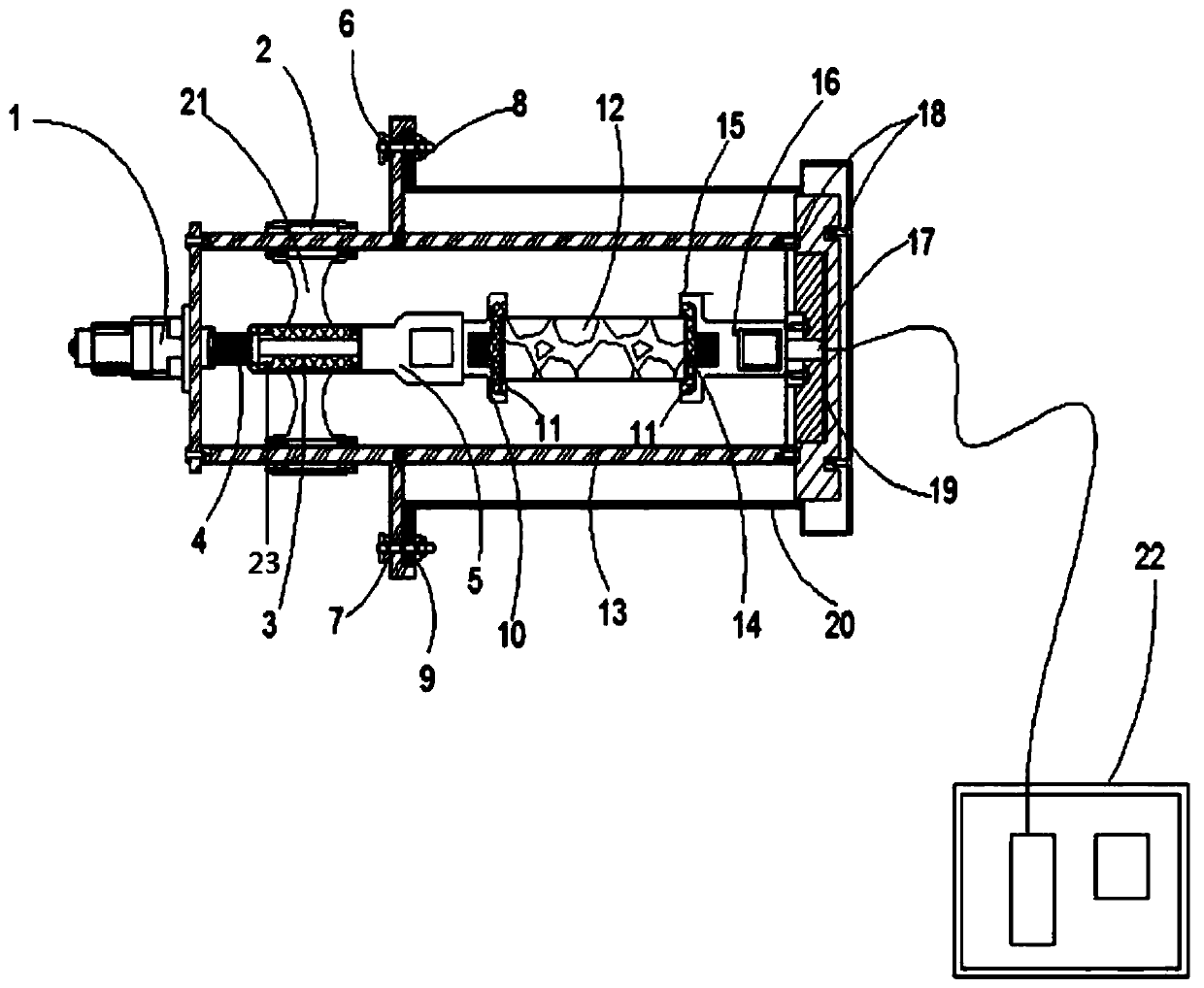

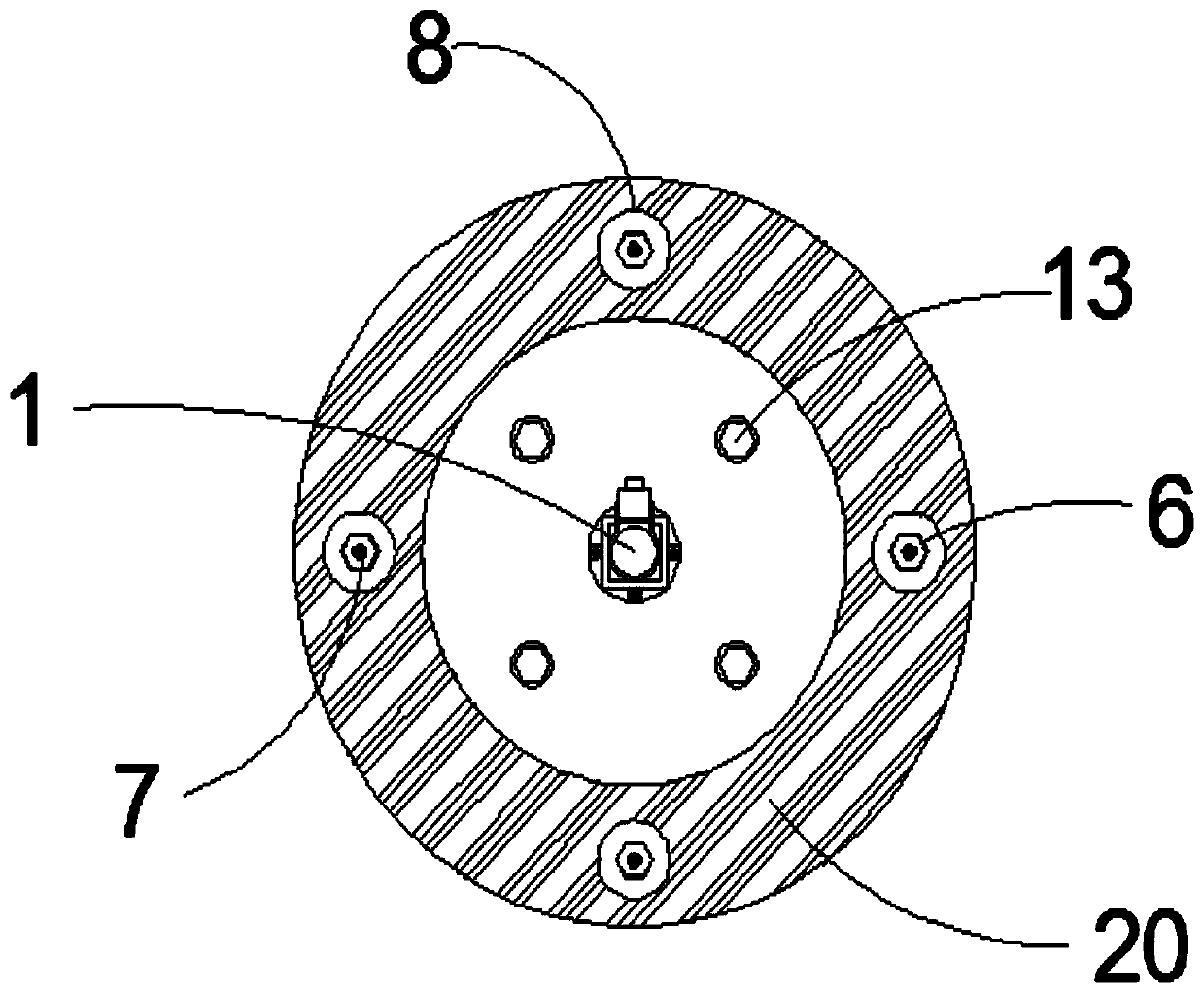

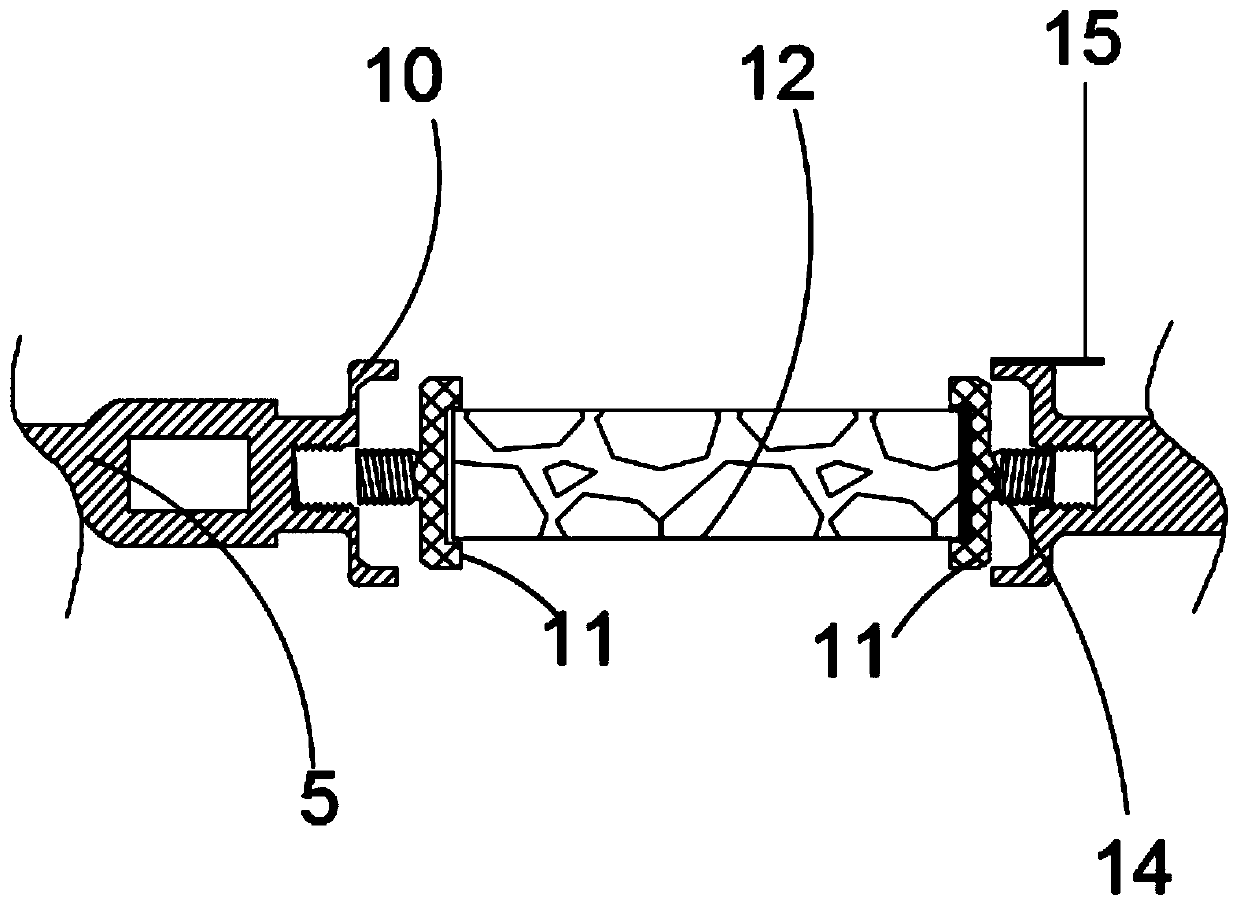

[0025] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically, as Figure 1-3 As shown, a portable loading device suitable for high and low temperature cycle test chambers and CT scanners includes baffles and pedestals 19 respectively arranged on both sides of the main body of the device, a loading motor 1 is arranged outside the baffle, and an output shaft of the loading motor 1 Connect the spiral connecting rod 4 after passing through the baffle, and connect and fix between the baffle and the pedestal 19 through several pull rods 13. After the spiral connecting rod 4 is connected with the loading pressure head 5, the load is transferred to the loading end plate connected with the loading pressure head 5 10. A fixed seat 16 is provided on the inner side of the pedestal 19, and a clamper 11 is arranged on the loading end plate 10 and the fixed seat 16 opposite to each other for clamping the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com