Nozzle cleaning device and nozzle cleaning method

A technology for cleaning devices and nozzles, applied in cleaning methods and utensils, spraying devices, chemical instruments and methods, etc., can solve the problems of removal of components that cannot be wiped, lack of treated objects, etc., and achieves the effect of reducing the area and improving the removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

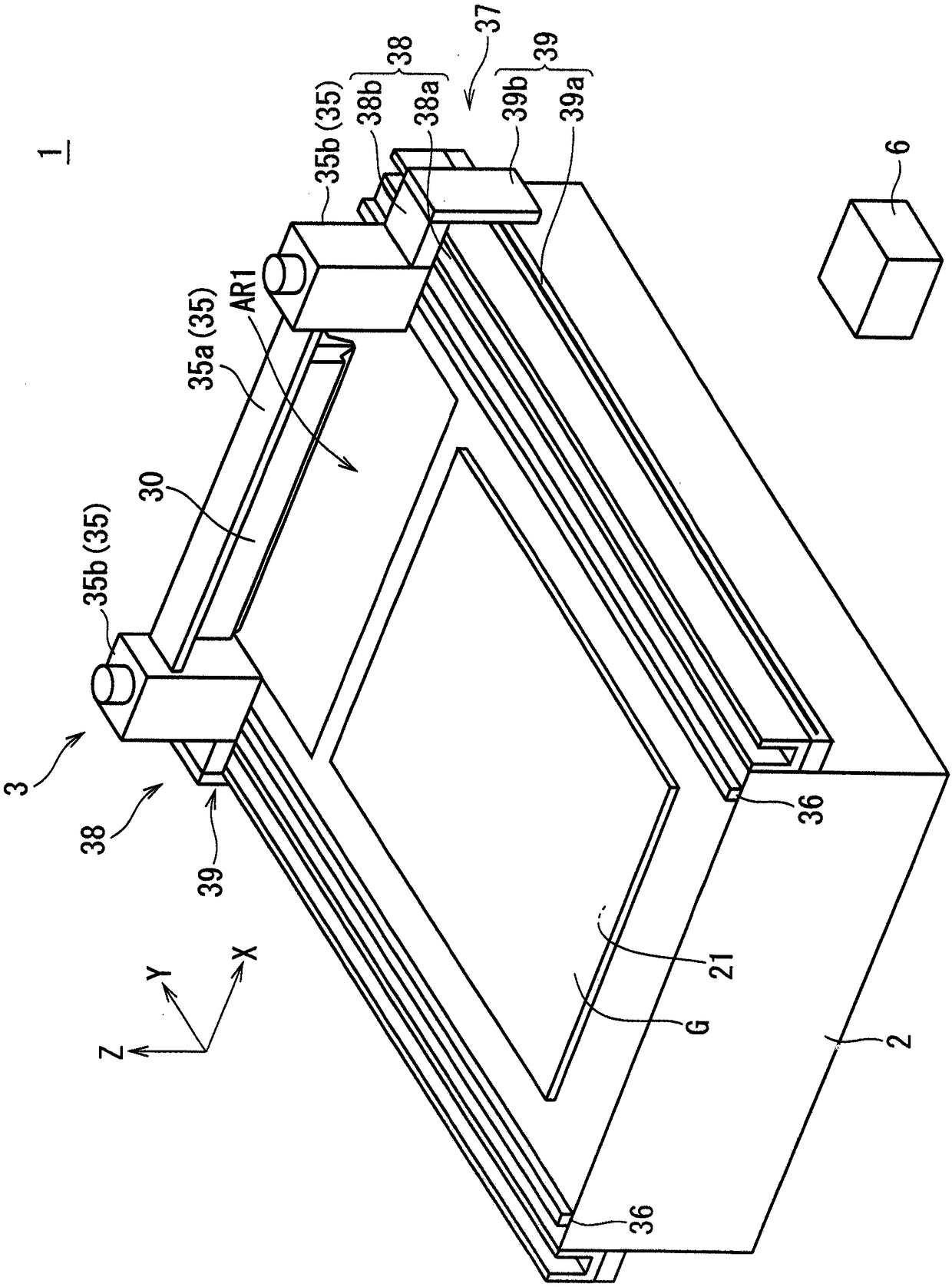

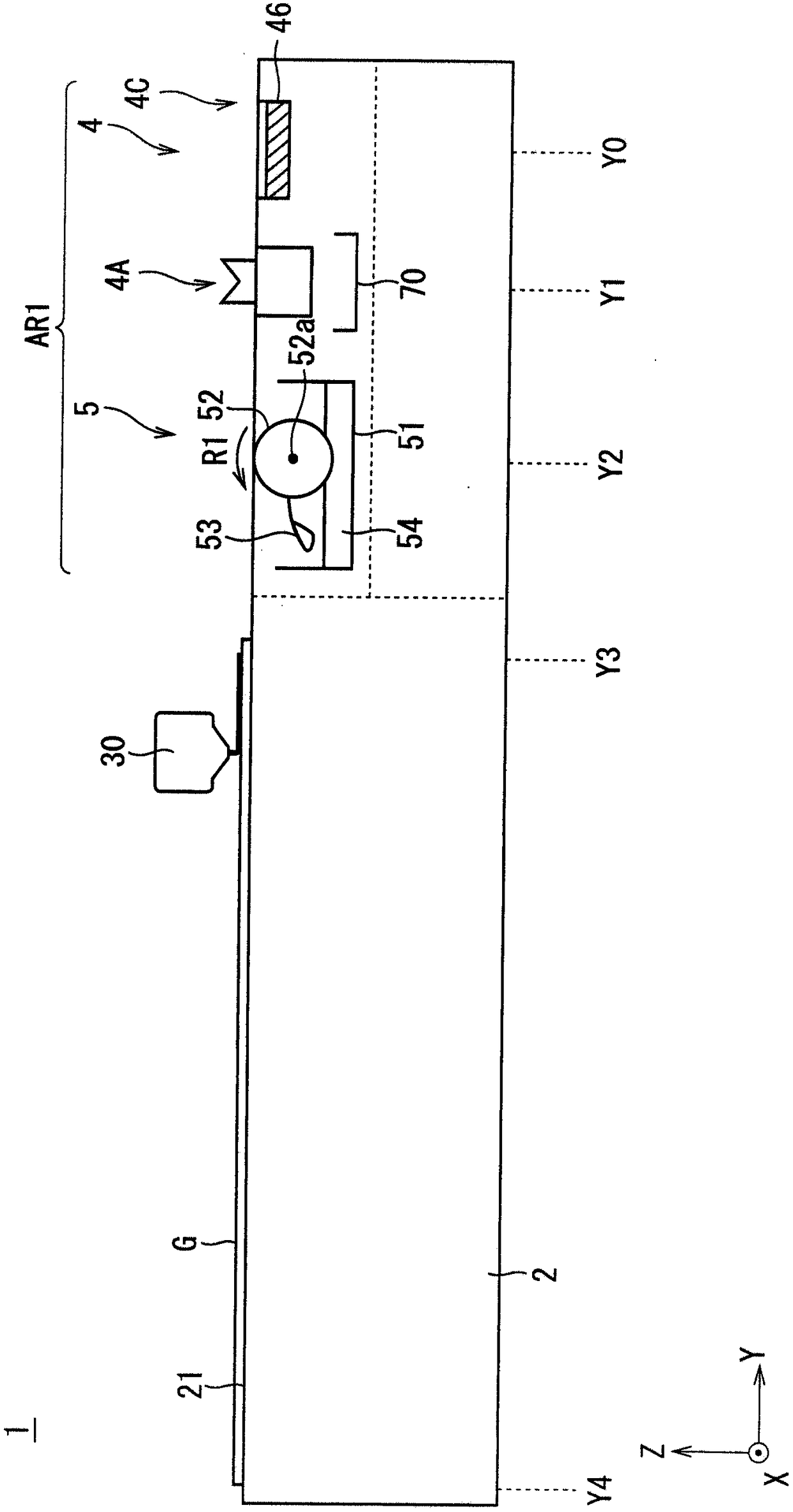

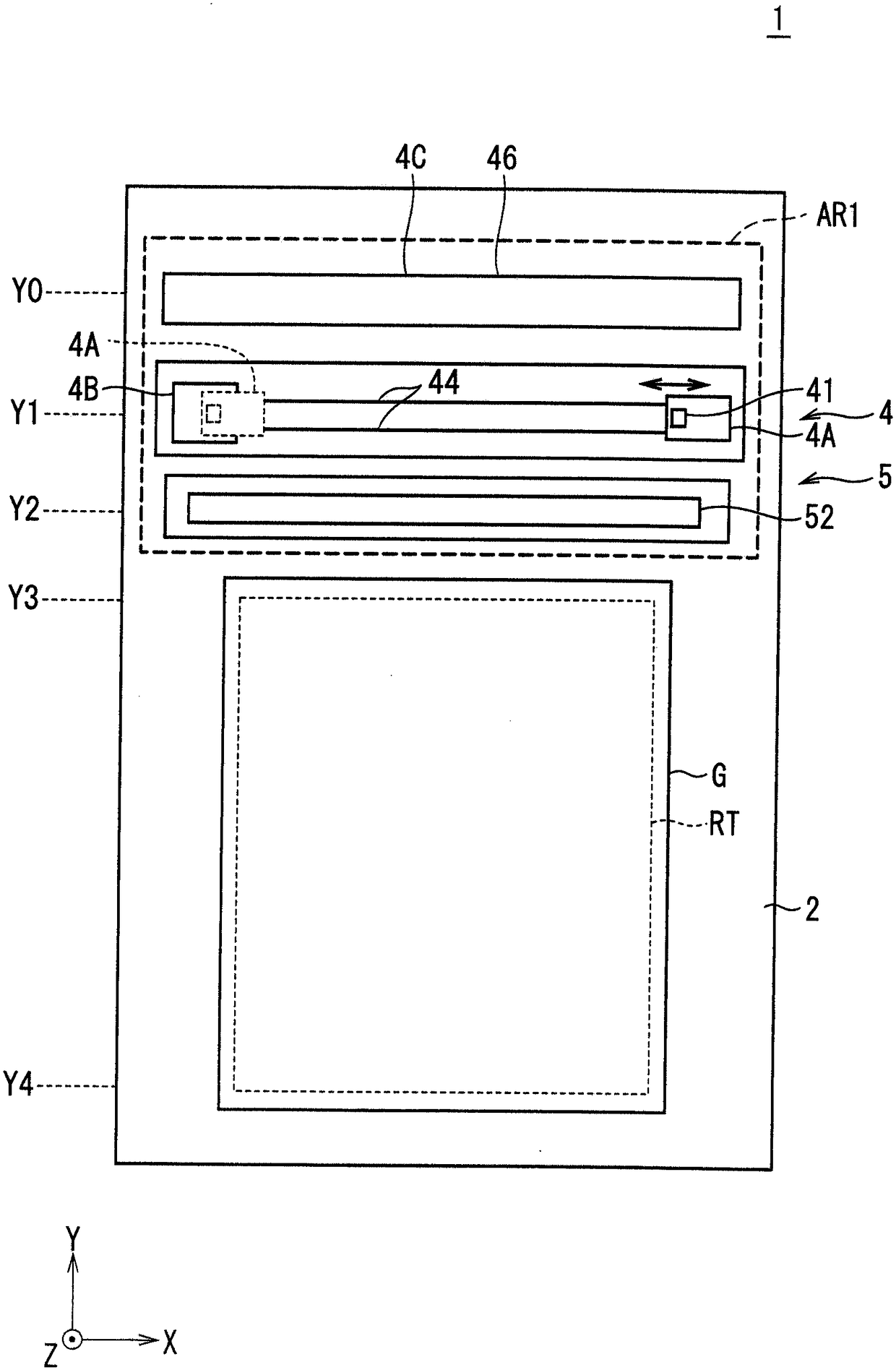

[0061]

[0062] figure 1 It is a perspective view schematically showing an example of the structure of the coating apparatus 1 of embodiment. Also, for clarity of direction, in figure 1 The XYZ Cartesian coordinate system in which the Z direction is the vertical direction and the XY plane is the horizontal plane is appropriately indicated in each of the following figures. In addition, the size and number of each part are exaggerated or simplified as necessary for easy understanding. In addition, descriptions of "+X-axis side" and "-X-axis side" are appropriately introduced in the following description. "+X-axis side" means one side in the X direction, and "-X-axis side" means the other side in the X direction. The same is true for other coordinate axes. In addition, "+Z axis side" means the upper side of Z direction.

[0063] The coating device 1 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com