Shear wall structure building assembly system design

A shear wall and system technology, applied in buildings, building structures, etc., can solve problems such as doubts about the seismic performance of prefabricated buildings, and achieve the effects of easy guarantee of construction quality, small amount of concrete poured on site, and easy guarantee of waterproof quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

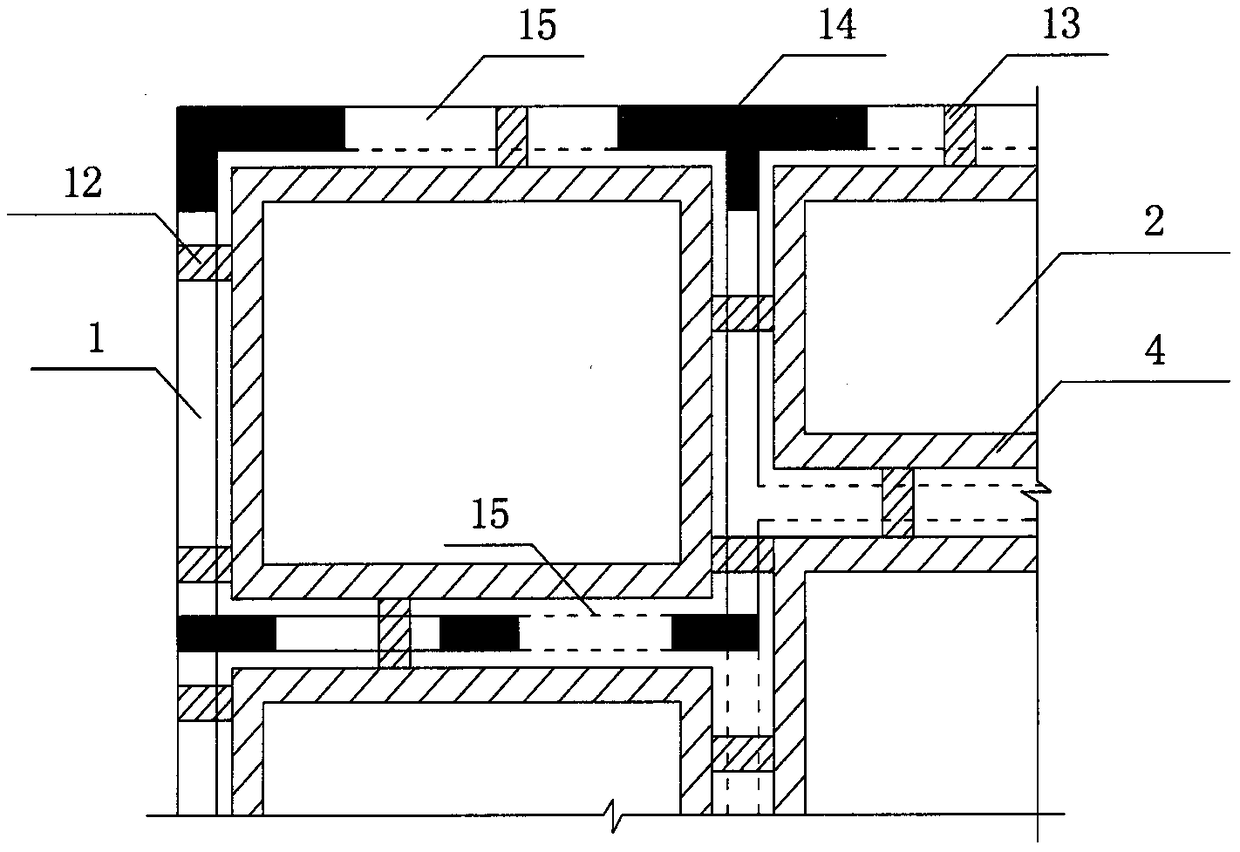

[0031] Specific embodiments of the present invention will be described in detail below for further understanding of the present invention.

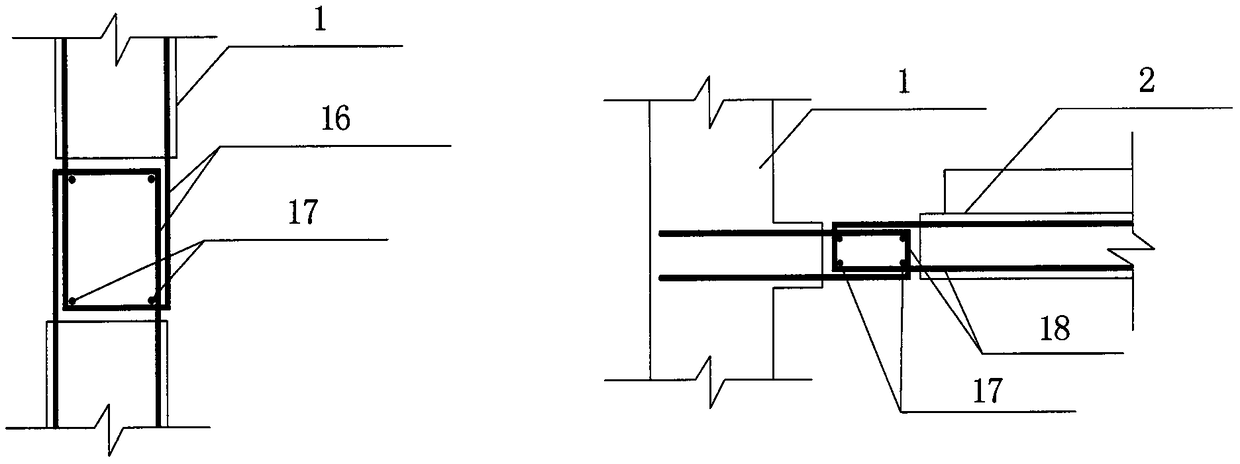

[0032] The present invention sets the cast-in-place belt at a reasonable position and adopts a new steel bar connection method and assembly reinforcement method to improve the seismic performance of the prefabricated building, improve the safety of weak parts such as the cast-in-place belt, ensure the waterproof quality of the room with water, reduce the The effect of the small amount of on-site concrete pouring helps to promote the development of prefabricated buildings.

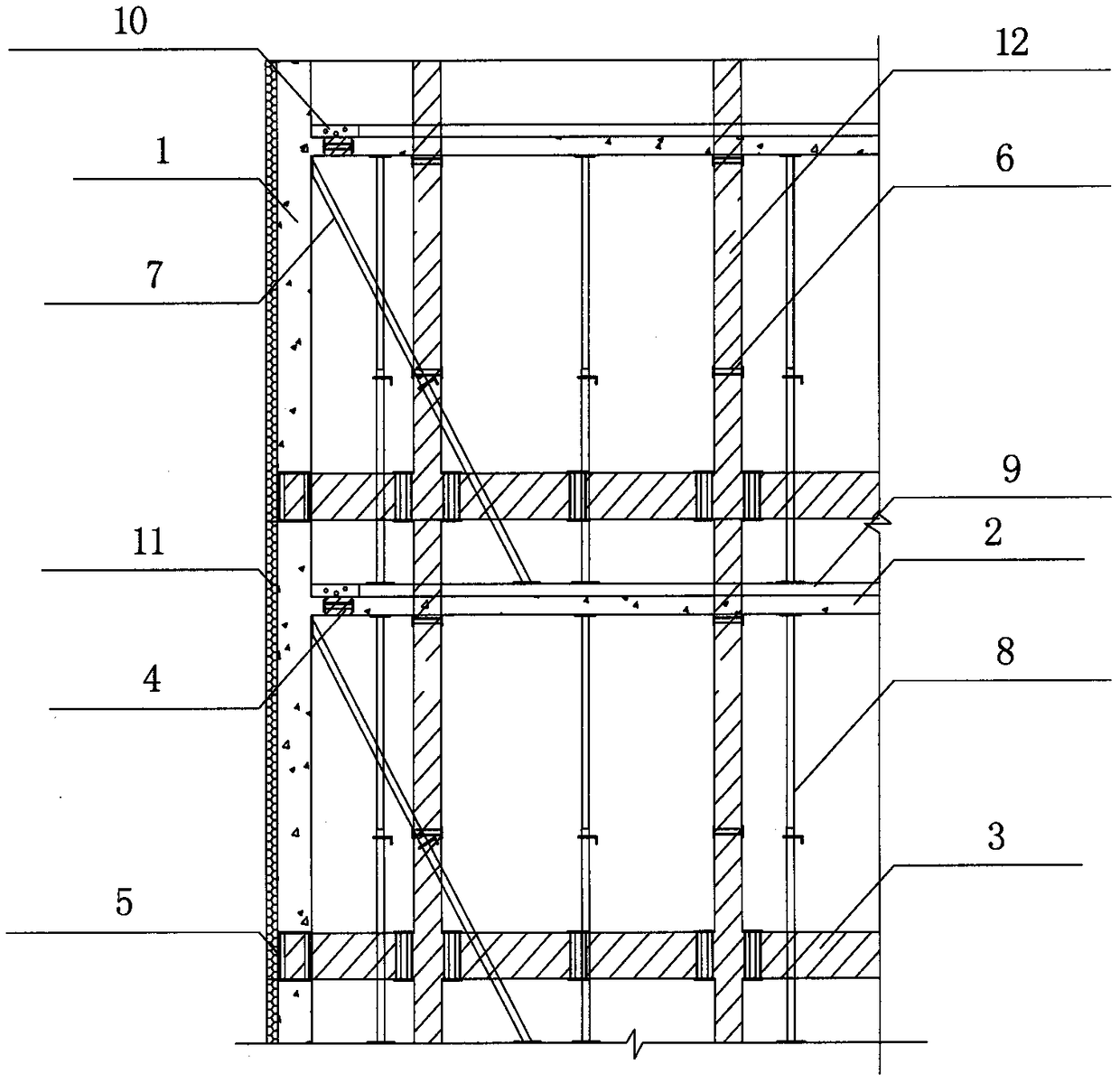

[0033] figure 1 It is a schematic design diagram of a shear wall structure building assembly system of the present invention. as the picture shows,

[0034] Shear wall 1 is prefabricated and segmented horizontal cast-in-place belt 3, that is, the steel bar connection area is set at the position where the vertical structure receives less shear force, that is, the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com