Hydraulic control system for full-power shifting and reversing tractor gearbox

A hydraulic control system and power shifting technology, applied in transmission control, mechanical equipment, transmission parts, etc., can solve problems such as shortened service life of parts, complex lubrication circuit system, accelerated driver fatigue, etc., to reduce production and manufacturing cost, simplify the layout of the hydraulic system, and avoid the effects of complex systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

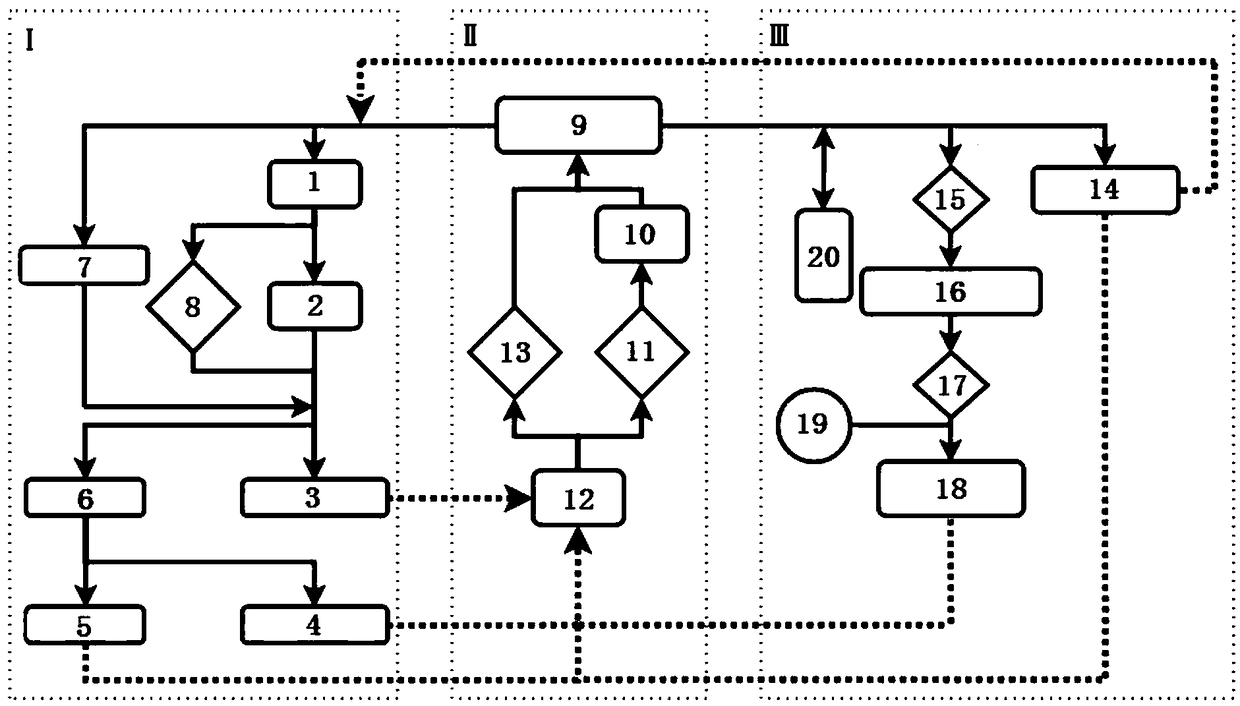

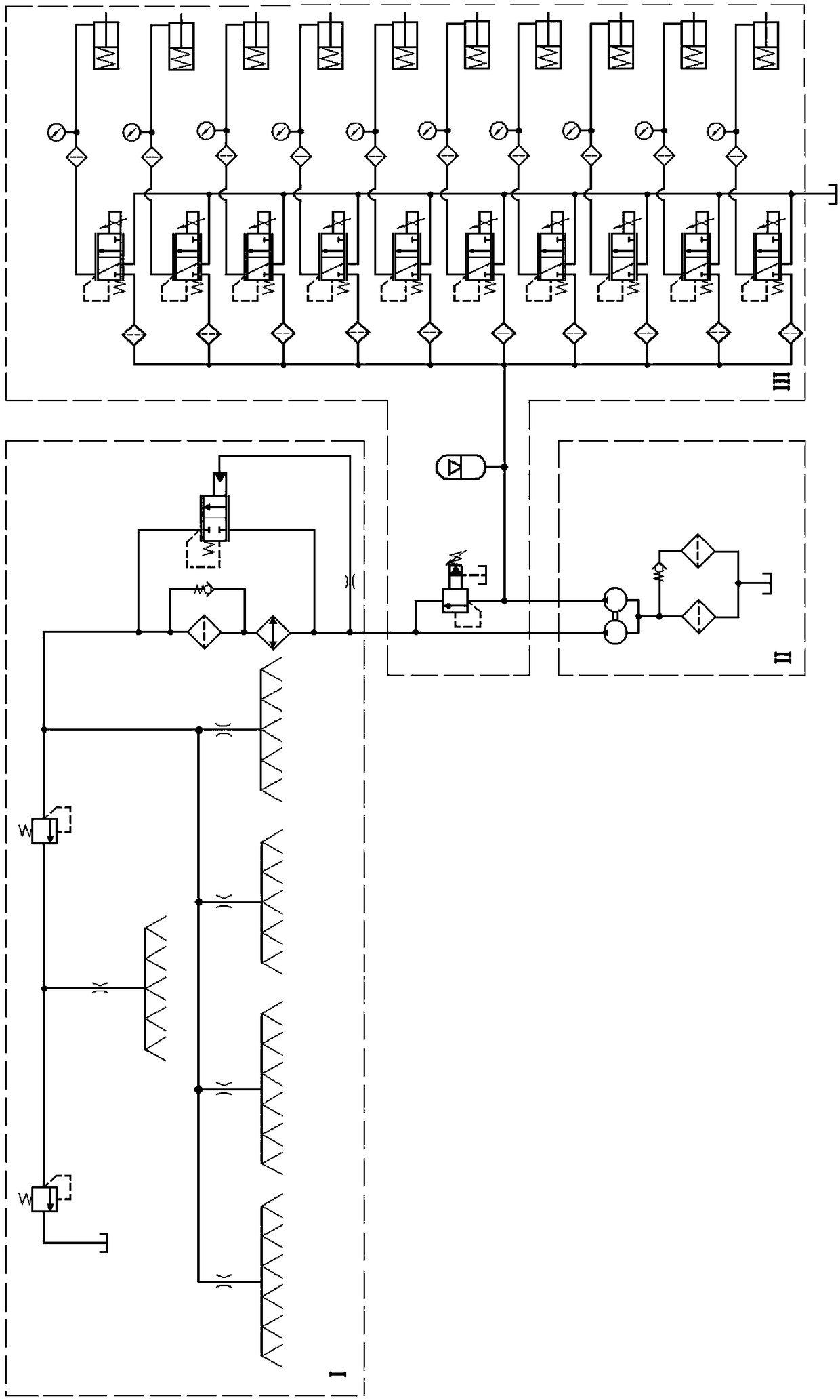

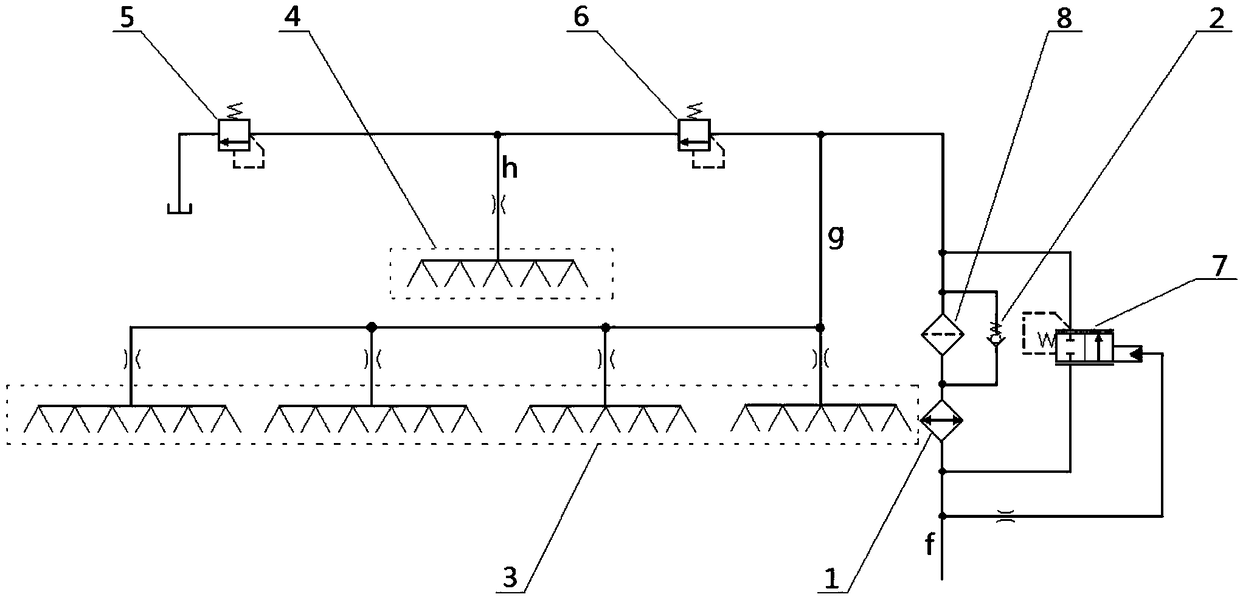

[0041] like figure 1 and figure 2 As shown, the present invention is composed of cooling and lubricating subsystem I, oil supply subsystem II and clutch control subsystem III. The oil inlet of cooler 1 in system Ⅰ is connected; the large displacement oil discharge port i of double gear pump 9 in oil supply subsystem Ⅱ is also connected with the control pilot end of hydraulic control bypass valve 7 in cooling and lubricating subsystem Ⅰ connected. The small displacement oil discharge port j of the dual gear pump 9 in the oil supply subsystem II communicates with the oil inlet port of the pilot overflow valve 14 in the clutch control subsystem III. The overflow oil port of the secondary relief valve 5 in the cooling lubrication subsystem I communicates with the oil return port of the oil tank 12 in the oil supply subsystem II. The overflow oil port of the pilot relief valve 14 in the clutch control subsystem III communicates with the branch circuit where the oil inlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com