Composite tubular product for constructing sponge city

A composite pipe and sponge city technology, applied in the field of composite pipes, can solve problems such as inability to seep water and store water, and achieve the effects of improved anti-corrosion performance, strong corrosion resistance and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

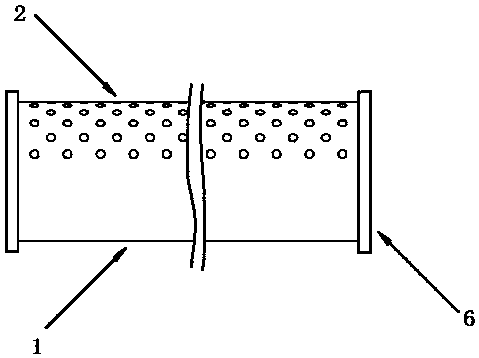

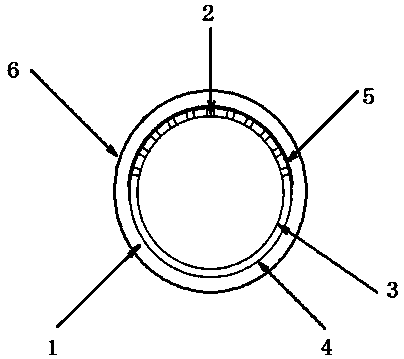

[0016] attached figure 1 and figure 2 , and the two accompanying drawings show the specific structure of Embodiment 1 of the composite pipe material for constructing the sponge city proposed by the present invention. The composite pipe includes a base pipe 1, a cylindrical through hole 2, an inner anti-corrosion layer 3, an outer anti-corrosion layer 4, a permeable membrane 5 and a connecting piece 6, wherein the cylindrical through hole 2 is arranged on the upper half of the base pipe 1 Inside and through the pipe wall, the inner anti-corrosion layer 3 is arranged on the inner surface of the base pipe 1 and extends to the inner surface of the cylindrical through hole 2, and the outer anti-corrosion layer 4 is arranged on the outer surface of the base pipe 1 , the surface of the upper part of the outer anti-corrosion layer 4 is provided with a permeable membrane 5, that is, the permeable membrane 5 covers the outside of the columnar through hole 2, and the inner anti-corrosi...

Embodiment 2

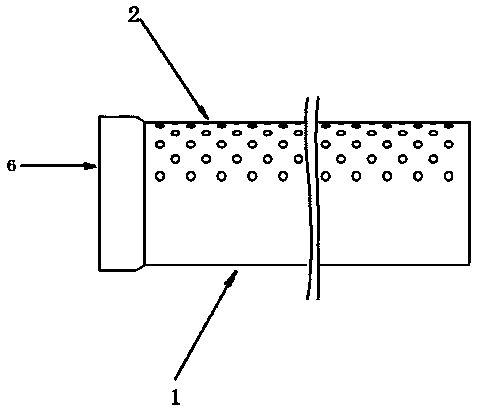

[0018] see image 3 , gives the specific structure of Embodiment 2 of the composite pipe material for constructing the sponge city proposed by the present invention. The difference between this embodiment and the first embodiment is that the connecting piece 6 is formed by a flared port arranged on one side of the pipe end for socket connection, and other structures are the same as those of the first embodiment.

[0019] The present invention can absorb the accumulated water on the ground, filter the infiltrated accumulated water on the surface through the permeable membrane 5, and infiltrate the filtered accumulated water into the pipe for storage or transportation through the columnar through hole 2. It has the functions of filtering water, It has the characteristics of water seepage, water storage and hydrophobicity, and has strong corrosion resistance. At the same time, the connection between the pipes can be more conveniently connected through the connector 6, and the ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com