External gas source isolation type double-energy-saving cooking fume removal stove

An isolated and air source technology, applied in the direction of oil fume removal, household stoves, heating methods, etc., can solve the problems of increasing the cost of indoor air reprocessing, affecting the normal opening and closing of doors and windows in the kitchen and other rooms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

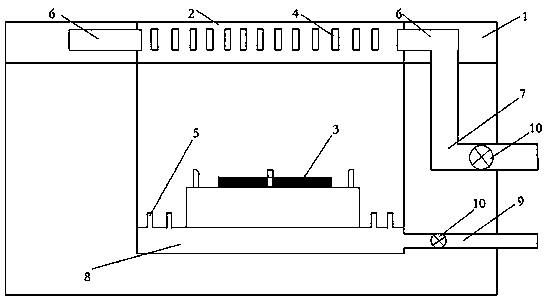

[0035] Such as figure 1 As shown in the figure, a double energy-saving oil and fume removal stove with isolated external air sources includes a table top 1, an air inlet chamber 6 and an air outlet chamber 8. A stove mouth 2 is opened on the table top 1, and a burner 3 is installed under the stove mouth. , several air inlets 4 are arranged in the table top, and the air inlets 4 are evenly distributed along the inner wall of the stove mouth 2; a number of air outlets 5 are arranged on the outside of the burner 3, and the air outlets 5 are evenly distributed on the burner 3 Outside; the air inlet chamber 6 communicates with each air inlet 4; the air outlet chamber 8 communicates with each air outlet 5; when in use, the air inlet 4 and the air outlet 5 can pass through the air inlet chamber 6 and the air outlet The cavity 8 communicates with the outside.

[0036] The air inlet chamber 6 is installed in the table top 1; the air outlet chamber 8 is installed below the burner 3; it...

Embodiment 2

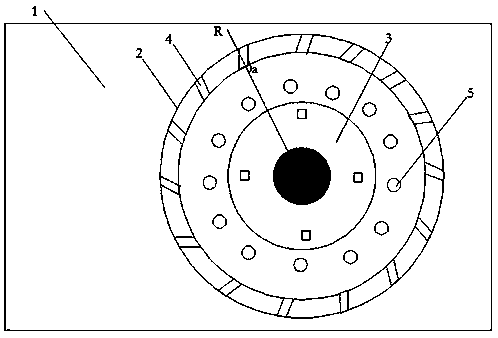

[0039] This embodiment is similar to Embodiment 1, further, the air intake direction of the air inlet 4 forms an angle a with the radial direction R of the stove mouth 2 in the horizontal plane, and the air intake direction of the air inlet 4 is vertical The plane is inclined downward; the air outlet 5 is arranged obliquely, and the air outlet direction of the air outlet 5 is consistent with the air intake direction of the air inlet 4 . In order to make the air entering the stove mouth 2 form a gas vortex in the stove mouth 2 during use, so as to achieve a better effect of gathering hot gas and oil fume (similarly, when using this embodiment, the air inlet can also be used as the air outlet , use the air outlet as the air inlet, and work in the opposite airflow circulation mode of this embodiment to achieve the same purpose).

Embodiment 3

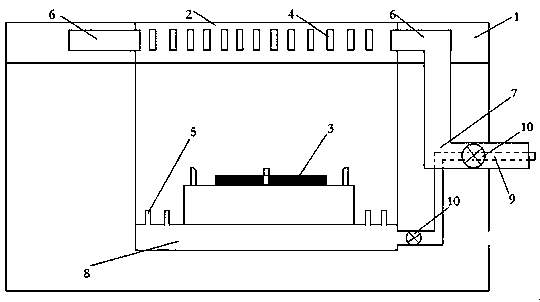

[0041] This embodiment is similar to Embodiment 2, and further includes an air outlet chamber 8 and an air outlet pipe 9, the air outlet chamber 8 communicates with each air outlet 5, and the air outlet chamber 8 is installed below the burner 3; One end of the trachea communicates with the outlet cavity 8 , and the other end is set in the outlet tube 9 and passes through the outlet tube 9 . During installation, the arrangement of the air outlet pipe and the air inlet pipe is convenient, and the installation of the air outlet pipe and the air inlet pipe can be completed on the same opening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com