Environmental vibration testing method and system

A vibration test and environment technology, applied in the field of physical simulation, can solve problems such as difficult to accurately obtain the global vibration response of the test object

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

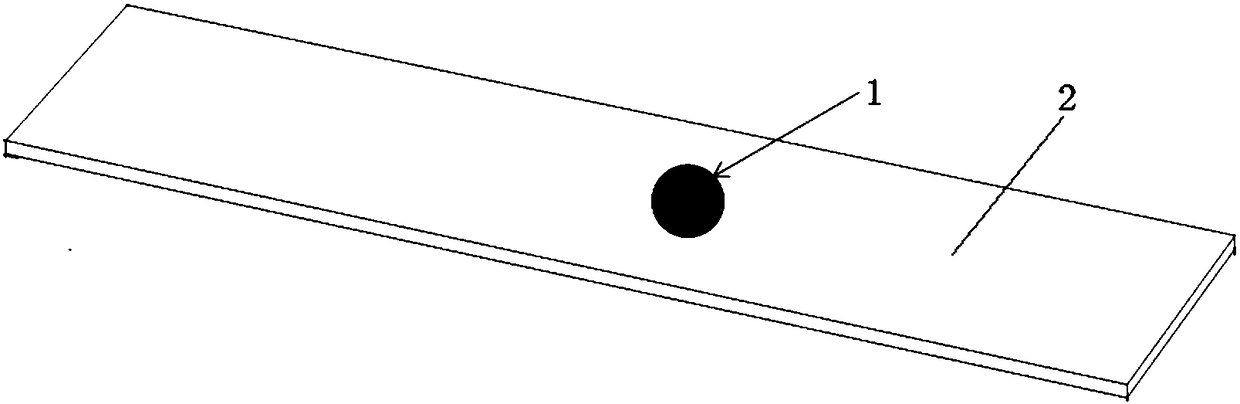

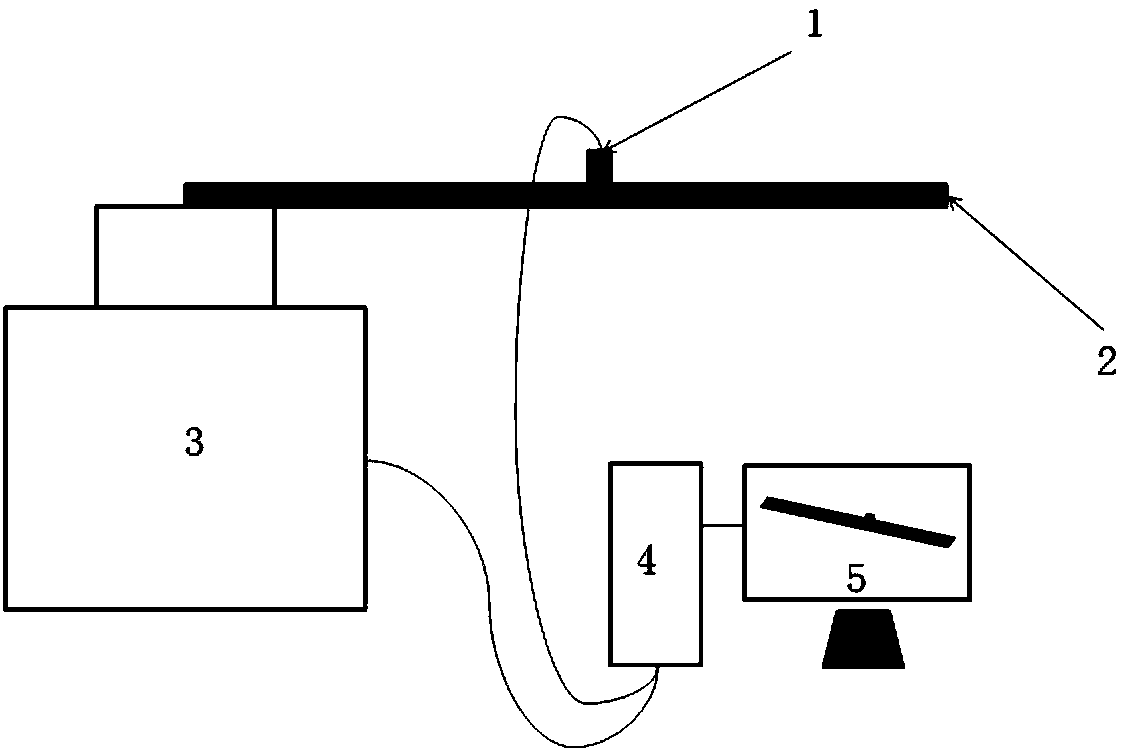

[0196] In this embodiment, for the aluminum beam 2 of rectangular section (such as figure 2 As shown), the environmental vibration test is carried out, and the length, width and height of the aluminum beam 2 are 22cm, 2.8cm and 0.8cm respectively. The vibration experiment table adopts the existing small vibration table. Before the vibration test, a first acceleration sensor (not shown) was arranged on the table of the vibration table, and a second acceleration sensor 1 was arranged at a pre-selected test point on the aluminum beam 2, and then necessary wiring connections were made. image 3 A schematic diagram of an environmental vibration test system according to an exemplary embodiment of the present invention is shown, which includes a vibration table 3 , a first acceleration sensor and a second acceleration sensor 1 , a processor 4 and a display unit 5 .

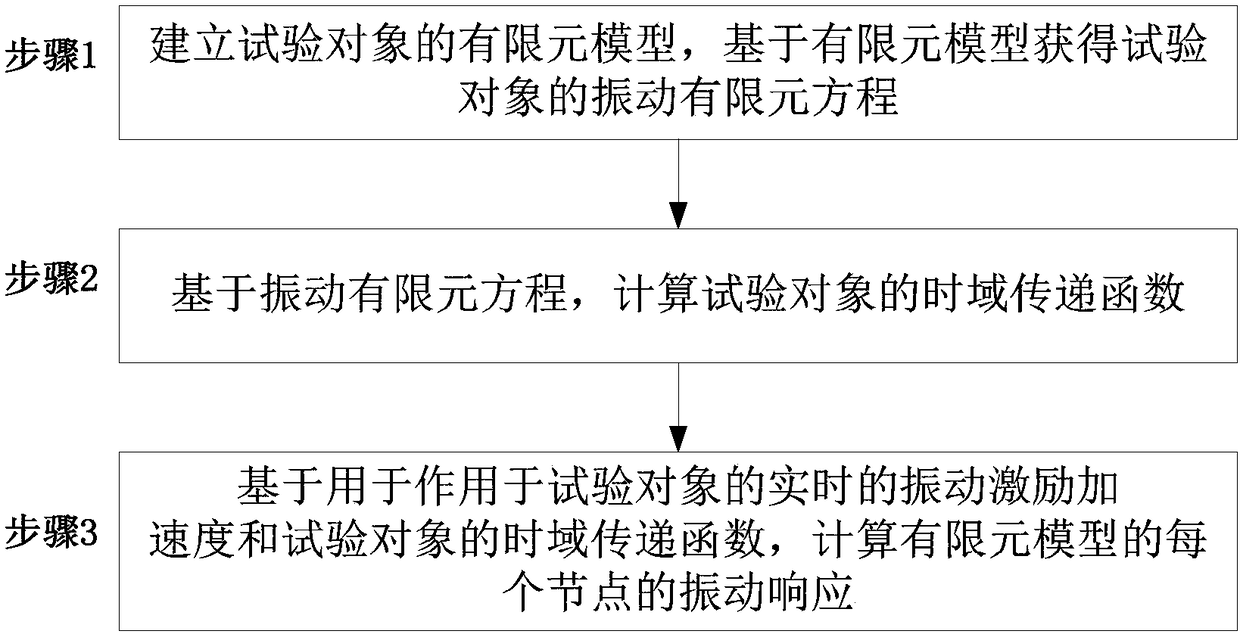

[0197] Follow the steps below to perform the vibration test procedure:

[0198] Step 1: Establish the finite elemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com