Compound cleaning and sorting screen of whole-feed harvester

A fully-feeding, harvester technology, applied in agricultural machinery and implements, threshing equipment, applications, etc., can solve the problem that large lumps cannot be sufficiently shaken, and achieves improved operation effect, fine control, The effect of strong cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

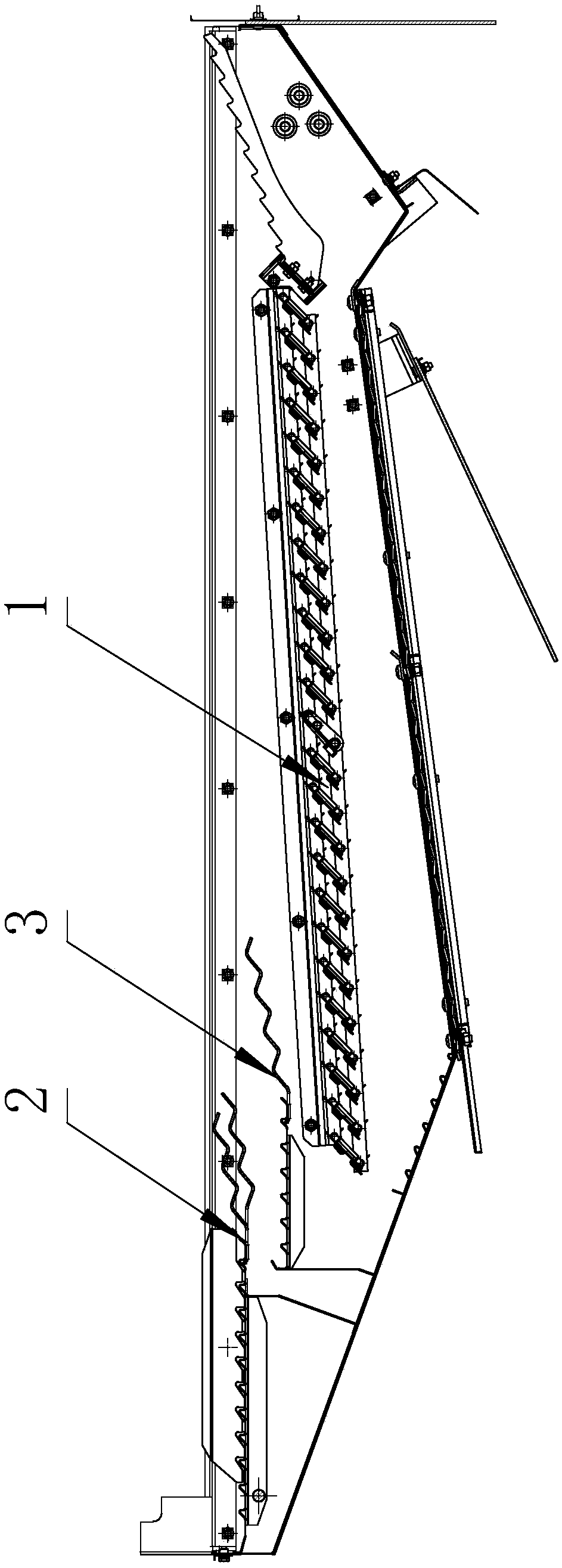

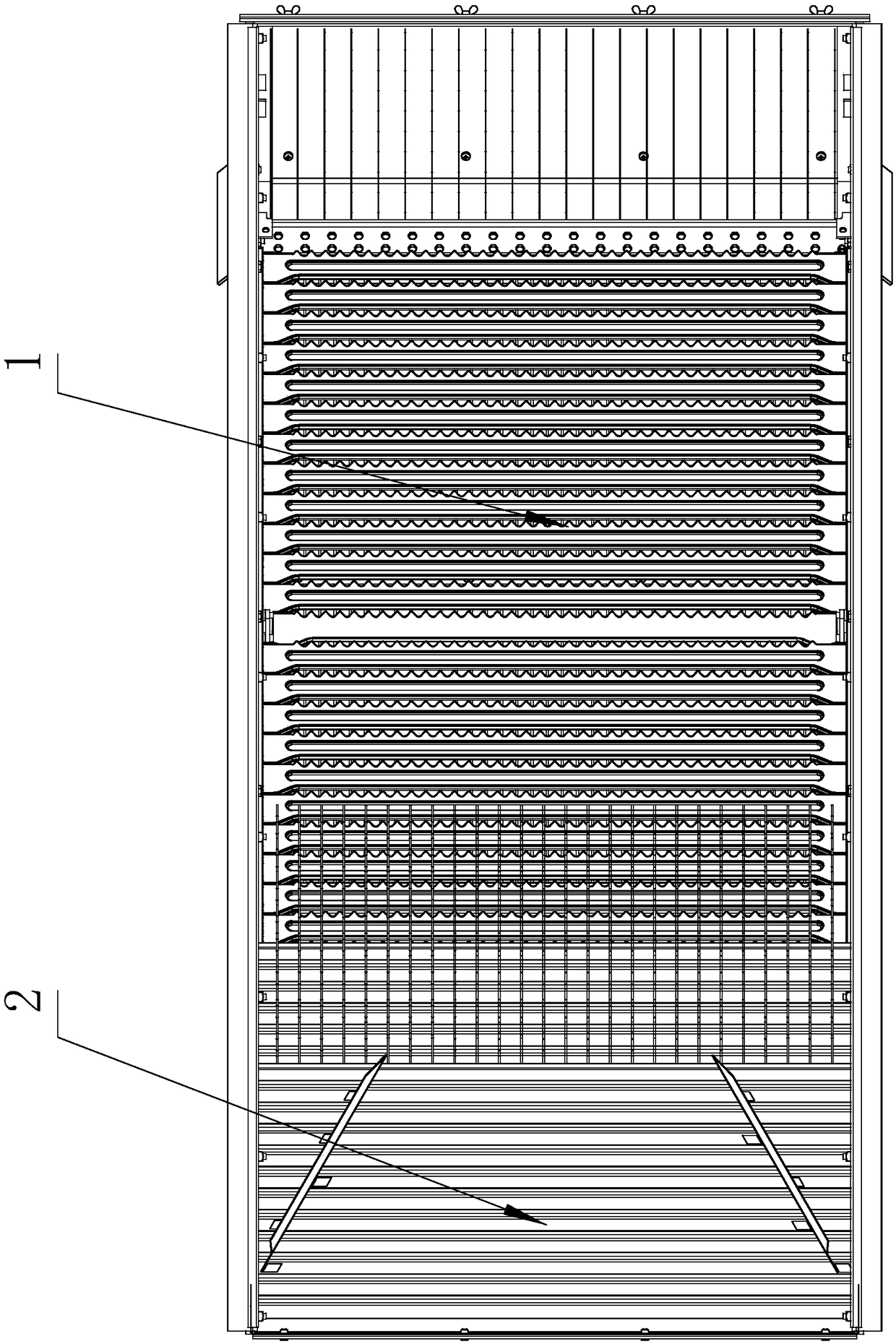

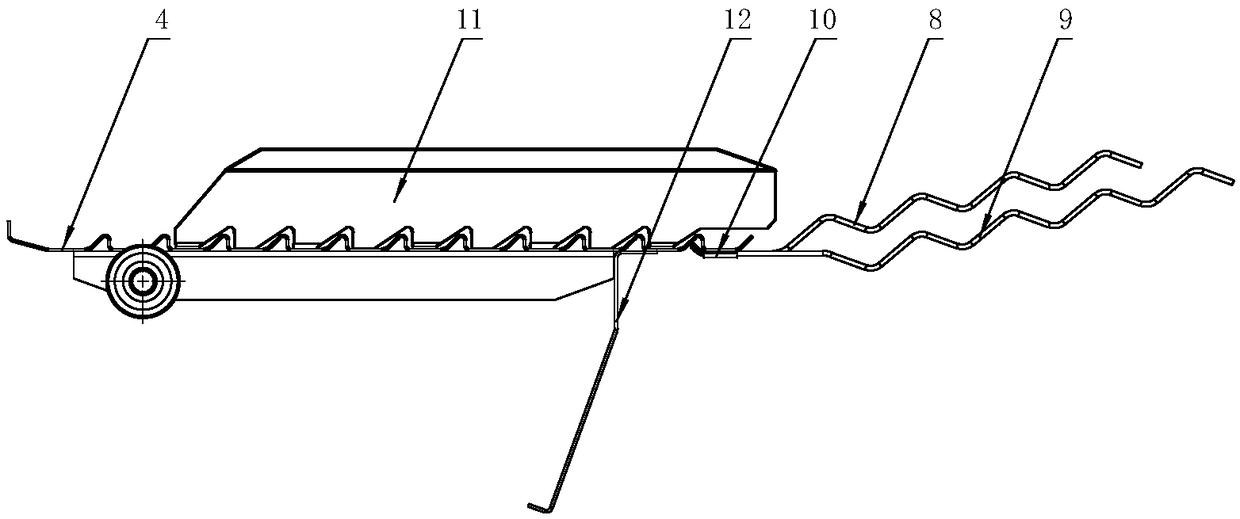

[0030] A compound cleaning sieve for a full-feed harvester, including a vibrating sieve and a louver sieve (1), characterized in that the vibrating sieve is double-layered and divided into a first vibrating sieve (2) and a second vibrating sieve The sieve (3), the first vibrating sieve (2), the second vibrating sieve (3) and the louver sieve (1) are distributed in steps from top to bottom, and the vibrating sieve includes a shaking plate (4) and a shaking The steel wire (5), the shaking plate (4) is connected with the shaking steel wire (5), and the shaking steel wire (5) of the first vibrating screen (2) is completely overlapped in the direction from top to bottom On the vibrating plate of the second vibrating screen (3), the vibrating steel wire (5) of the second vibrating screen (3) is completely overlapped on the louver screen (1) in the direction from top to bottom )superior. The shaking steel wire (5) is divided into a connecting part (6) and a shaking part (7) extendin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com