A kind of mfi structure nano-sheet molecular sieve catalyst, its preparation method and use

A nanosheet, molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low isomerization ratio of aviation kerosene fractions, poor thermal stability at high temperature, poor performance at low temperature, etc. Low cost, good isomerization effect, and the effect of improving deoxygenation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

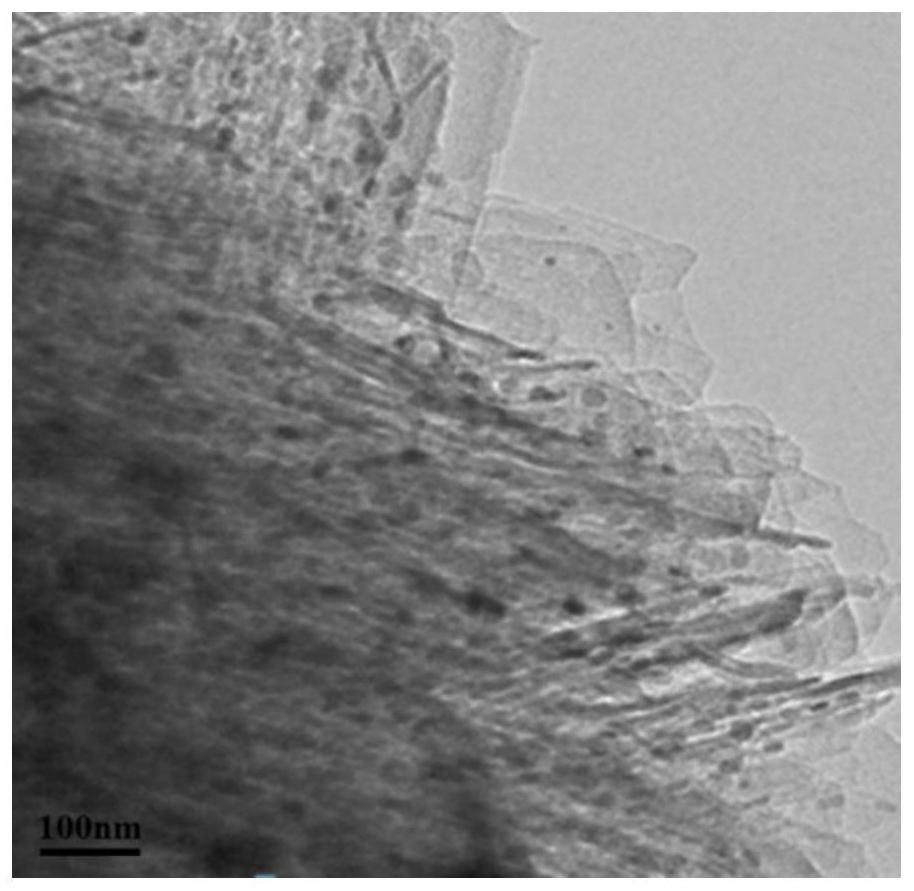

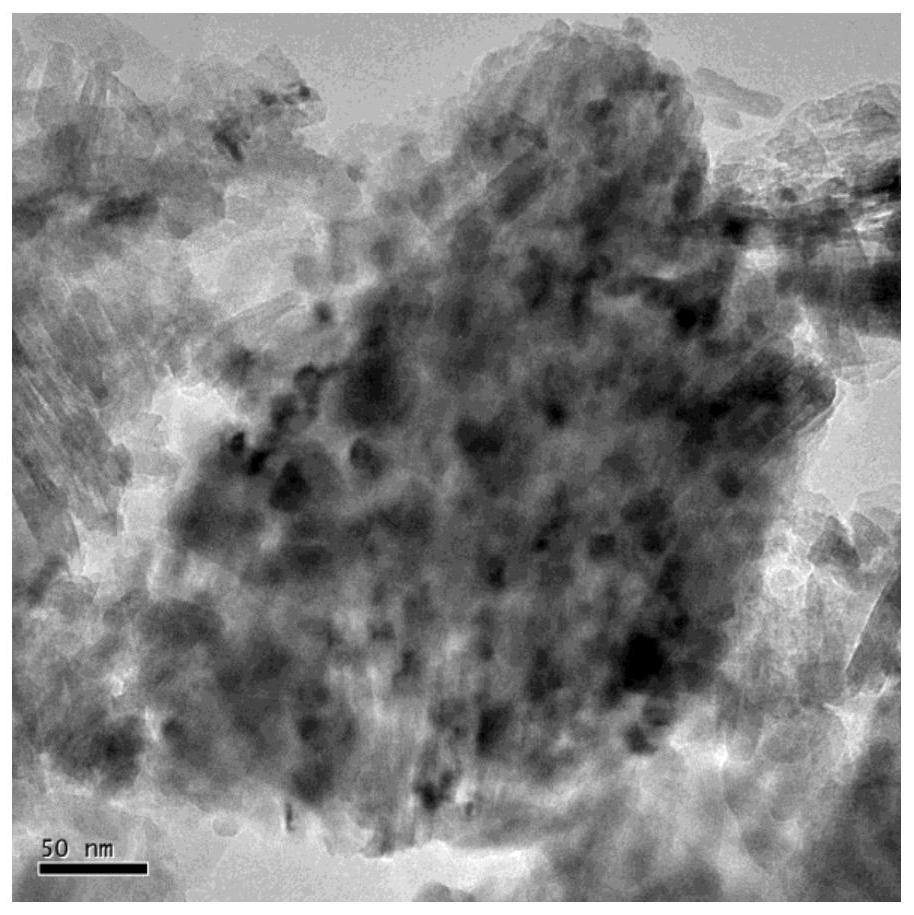

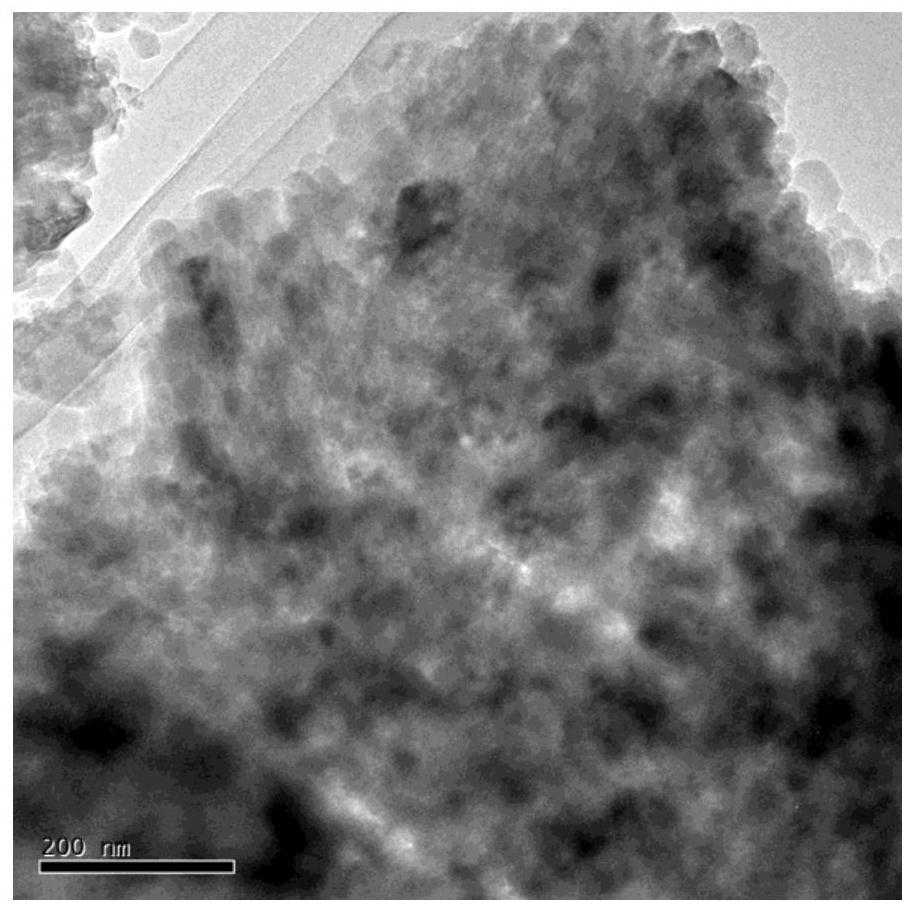

[0037]The TEM image of the catalyst prepared in Examples 1-3 is as followsFigure 1-3Shown. Fromfigure 1 It can be seen that the thickness of the nanosheet layer is 2-3nm, and the size of the metal nanoparticle is about 8nm;figure 2 It can be seen that the thickness of the nanosheet layer is 8-12nm, and the size of the metal nanoparticle is about 12nm;image 3 It can be seen that the thickness of the nanosheet layer is 20-30nm, and the size of the metal nanoparticle is about 20nm. The above description has achieved quantitative control of the thickness of the catalyst nanoplatelets by changing the amount of template agent added in the molecular sieve crystallization solution. The amount of template used in Example 1 is approximately lower than 33.3 wt% of the lowest used amount in the prior art.

[0038][Examples 4-10] Weigh 20.833g of TEOS and 0.111g of Al2(SO4)3·18H2O, 2.400g of NaOH, 3.528g of H2SO4Solution (mass fraction of 50.0wt%), 3.634g of double quaternary ammonium salt surfacta...

Embodiment 7

[0041]The TEM image of the catalyst prepared in Example 7 is as followsFigure 4 Shown. FromFigure 4 It can be seen that when the Ni loading amount is 20.0wt%, the metal nanoparticle size distribution in the prepared catalyst is relatively uniform, and the particle size is about 18nm. Comparative Example 1 shows that when the loading amount of Ni increases from 10.0% by weight to 20.0% by weight, the size of the nanoparticles increases from about 8nm to about 18nm.

[0042][Embodiment 11-17] where Al2(SO4)3·18H2The change in the amount of O, the ratio of the amount of silicon-aluminum substance in the synthesis solution from 10 to positive infinity, where the Al used in Example 112(SO4)3·18H2The mass of O is 3.332g, of which Al used in Example 122(SO4)3·18H2The mass of O is 1.111g, and the Al used in Example 132(SO4)3·18H2The mass of O is 0.3332g, and the Al used in Example 142(SO4)3·18H2The mass of O is 0.1667g, and the Al used in Example 152(SO4)3·18H2The mass of O is 0.1111g, and the...

Embodiment 11

[0043]The TEM image of Example 11 is asFigure 5 Shown. FromFigure 5 It can be seen that the thickness of the catalyst nanoplatelets is 2-3 nm. Comparative Example 1 shows that changing the ratio of silicon to aluminum in the crystallization solution has almost no effect on the thickness of the catalyst nanolayer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com