Wooden furniture paint spraying device

A spraying device and paint technology, which is applied in the direction of spraying devices, can solve the problems of complex structure, low efficiency and unsafe operation of the spraying device, and achieve the effects of high spraying efficiency, reduced operating noise and guaranteed safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

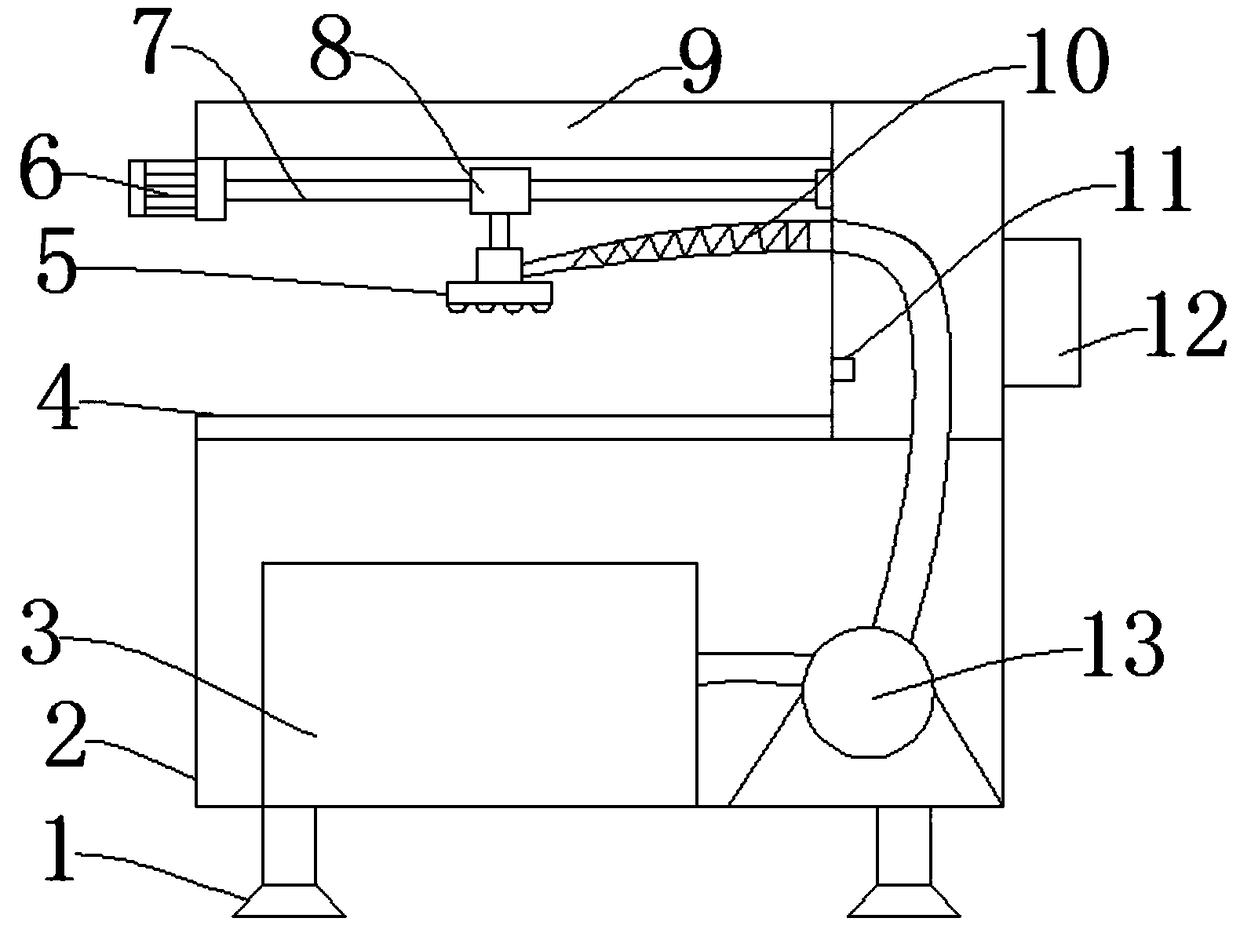

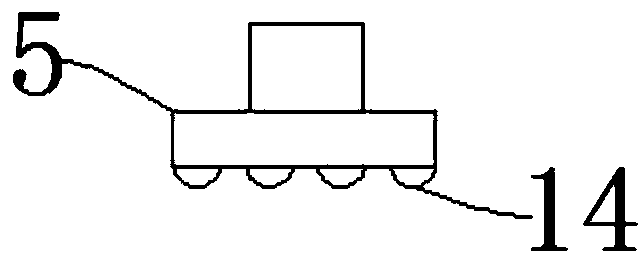

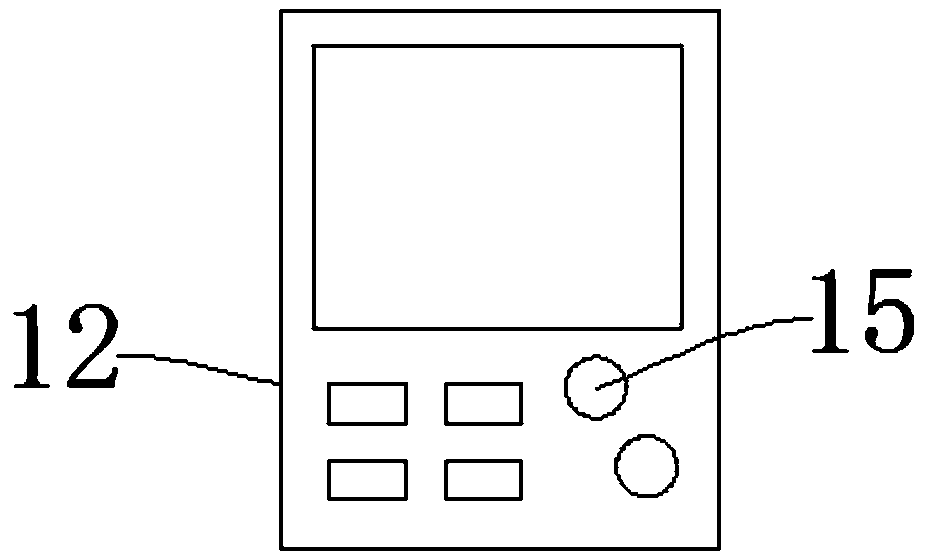

[0018] Such as figure 1 , figure 2 and image 3 As shown, this specific embodiment adopts the following technical solutions: it includes a bottom support foot 1, a cabinet body 2, a paint storage box 3, a workbench 4, a sprinkler head 5, a servo motor 6, a ball screw 7, and a ball guide bush 8 , support beam 9, corrugated pipe 10, paint surface detector 11, operation control box 12, paint pump 13, high-pressure nozzle 14, liquid crystal operation panel 15, a cabinet body 2 is arranged above the bottom support foot 1, and the inside of the cabinet body 2 is provided with A paint storage box 3, a workbench 4 is arranged above the cabinet body 2, a sprinkler head 5 is arranged above the workbench 4, a servo motor 6 is arranged on one side of the sprinkler head 5, a ball screw 7 is arranged above the servo motor 6, and a ball screw 7 is arranged on the top of the servo motor 6. The ball guide bushing 8 is arranged on the screw rod 7, the support beam 9 is arranged above the bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com