A method for equidistant spiral rolling of large-size titanium alloy ultra-fine-grained rods

An equidistant spiral, titanium alloy technology, used in metal rolling, metal rolling, rolls and other directions, can solve the problems of low efficiency, large load, limited size, etc., to achieve large penetration, small load, rolling load small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

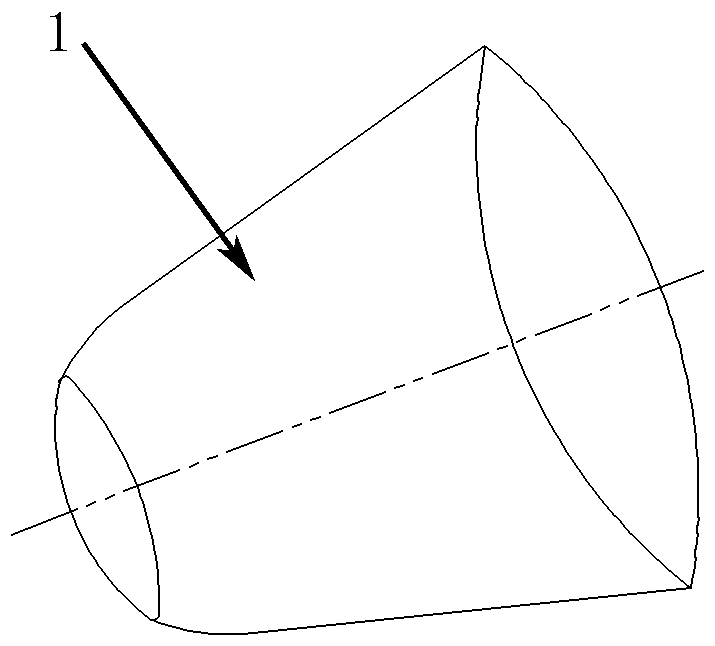

[0066] Using the above technical parameters, design and process roll 1 such as figure 1 shown;

[0067] S1: The main deformation parameters are titanium alloy TC18, the diameter D is 100mm, and the length is 800mm; the radius r of the biting arc of the spiral roll shape is 100mm, the feeding angle α is 16°, the cone angle is 17°, and the rolling angle is 17°, the roll distance Dg is 87.5% of the billet diameter D, the pass ellipticity coefficient is 1.23, and the speed n of roll 1 is 40r / min;

[0068] S2: Heating the cylindrical titanium alloy blank at 2 to 845°C in a heating furnace for 70 minutes;

[0069] S3: transfer the heated titanium alloy billet 2 from the heating furnace to the guide groove of the skew rolling mill, and the transfer time is 10s;

[0070] S4: The titanium alloy blank 2 moves helically in the deformation zone until the deformation ends.

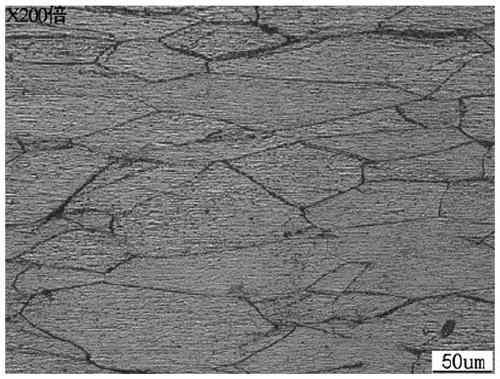

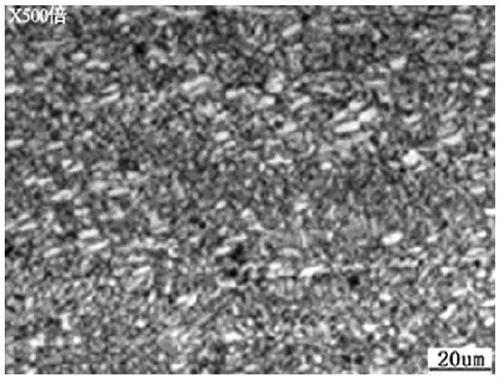

[0071] S5: Repeated rolling 2 times and 6 times sampling analysis, its effect on titanium alloy grain refinement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com