Spatial movement path planning method for laser cutting

A path planning and laser cutting technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as collision, cutting head scrap, plate deformation, etc., to achieve the effect of convenient use and collision avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

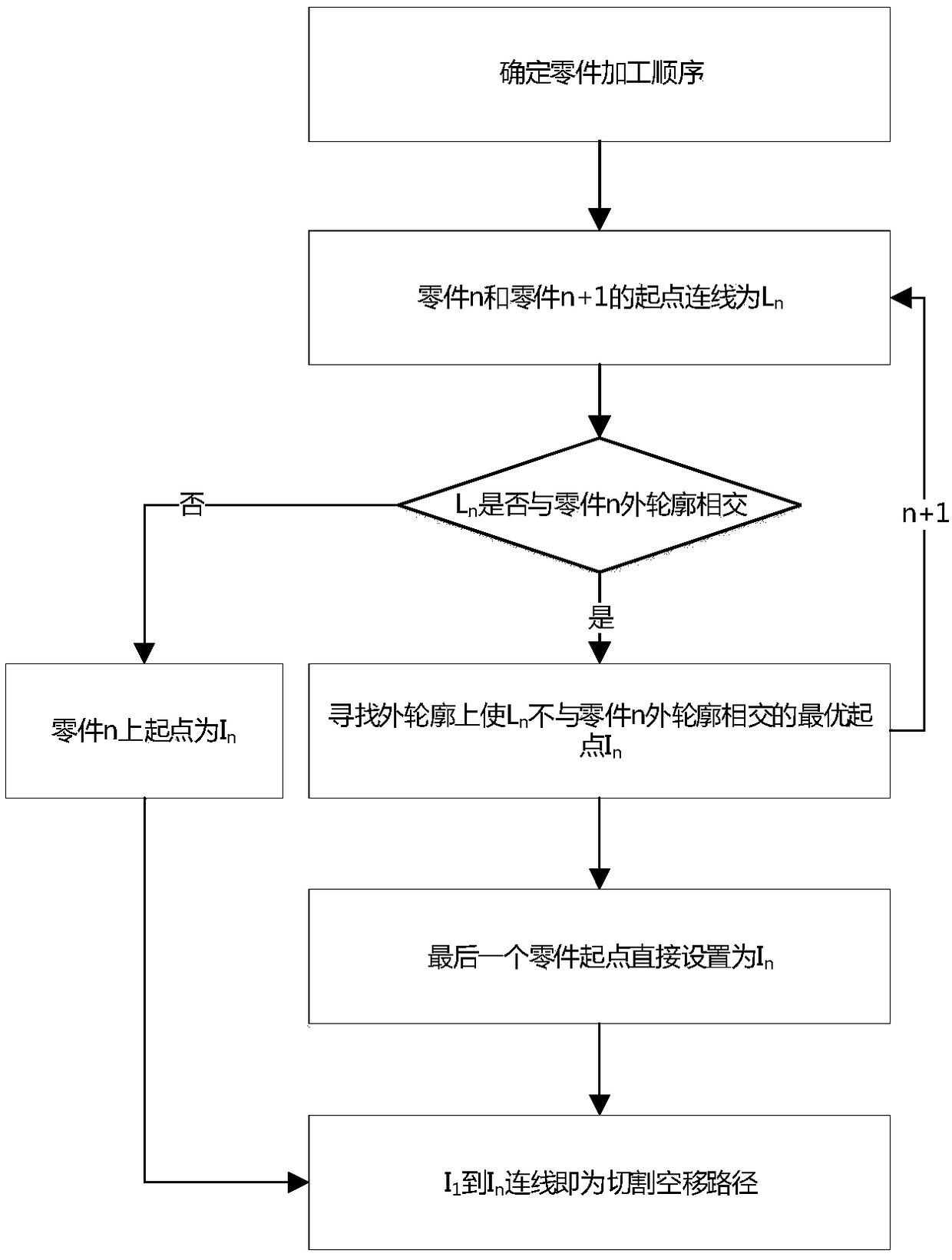

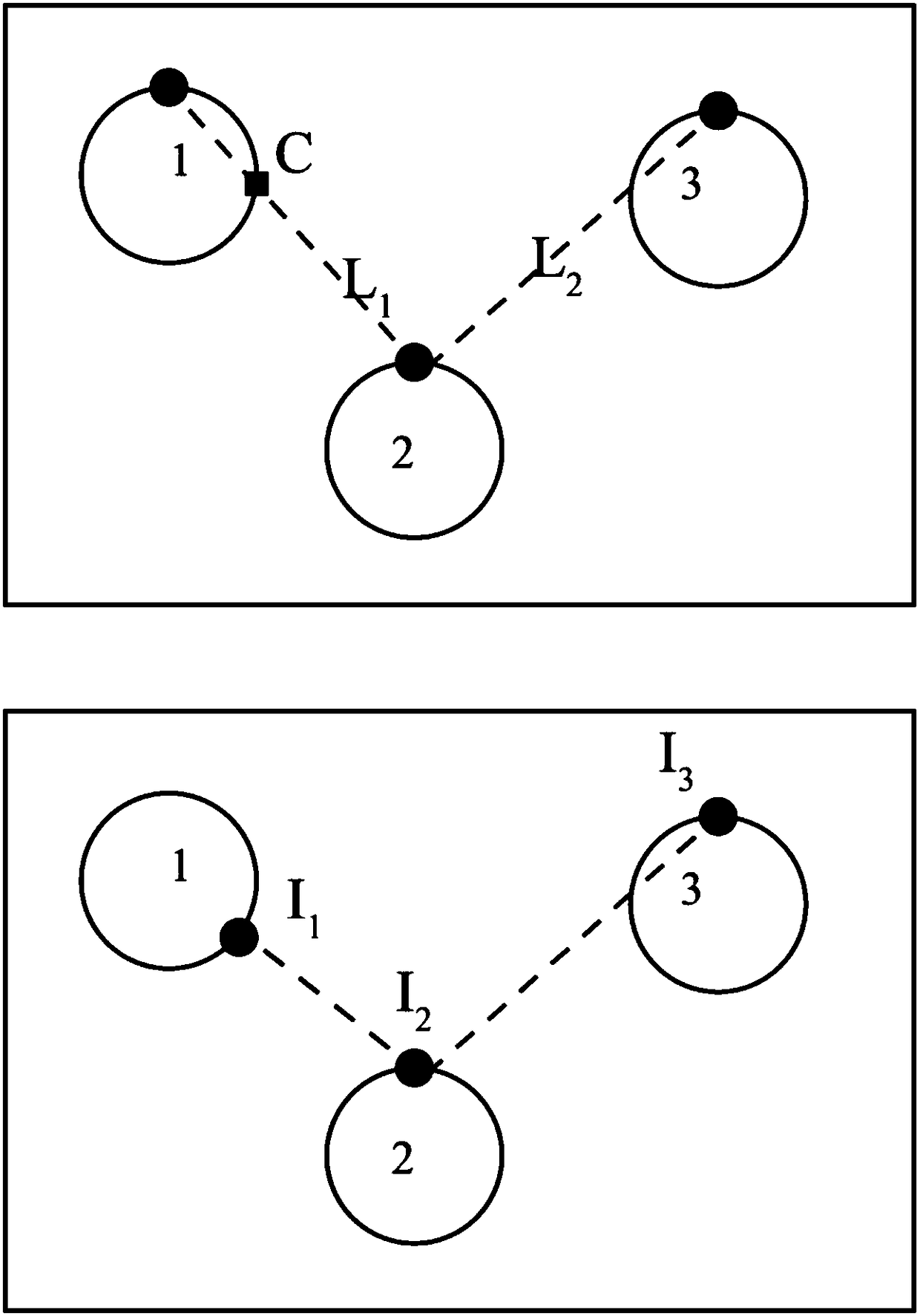

[0014] Such as figure 2 as shown, figure 2 The upper middle picture shows the original moving path of the laser head. The dots on part 1, part 2 and part 3 are the starting points of part cutting. The line between part 1 and part 2 is L1, and the line between part 2 and part 3 is The connection between is L2; figure 2 The middle and lower picture shows the planned air movement path of the laser head, and the dots on parts 1, 2, and 3 are the starting points I1, I2, and I3 of the laser head air movement. Find the cutting starting position of part 1 and part 2, and connect the two starting positions to form L1, and the remaining part 1 of L1 intersects at point C; the connection line L3 of part 2 and part 3 is the same. The head moves directly from the starting point of part 1 to the starting point of part 2 along L1, and then moves along L2 to the starting point of part 3. In the process of moving from part 1 to part 2, the laser head is very likely to Collision with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com