Movable service vehicle for continuous oil pipe butt-joint and detection

A service vehicle and oil pipe technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of limited coiled tubing length, inconvenient equipment transportation, and increased labor force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

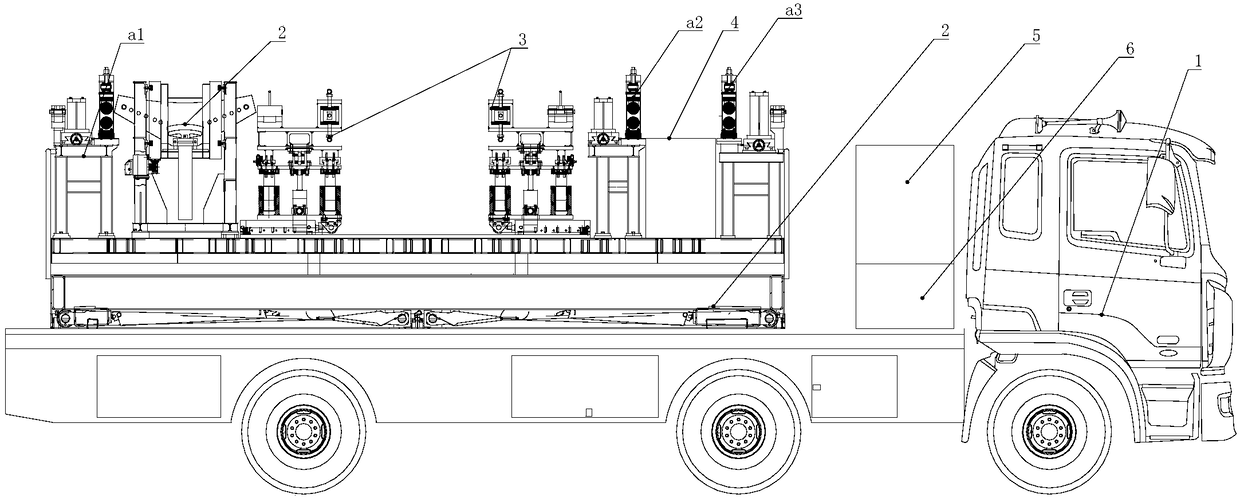

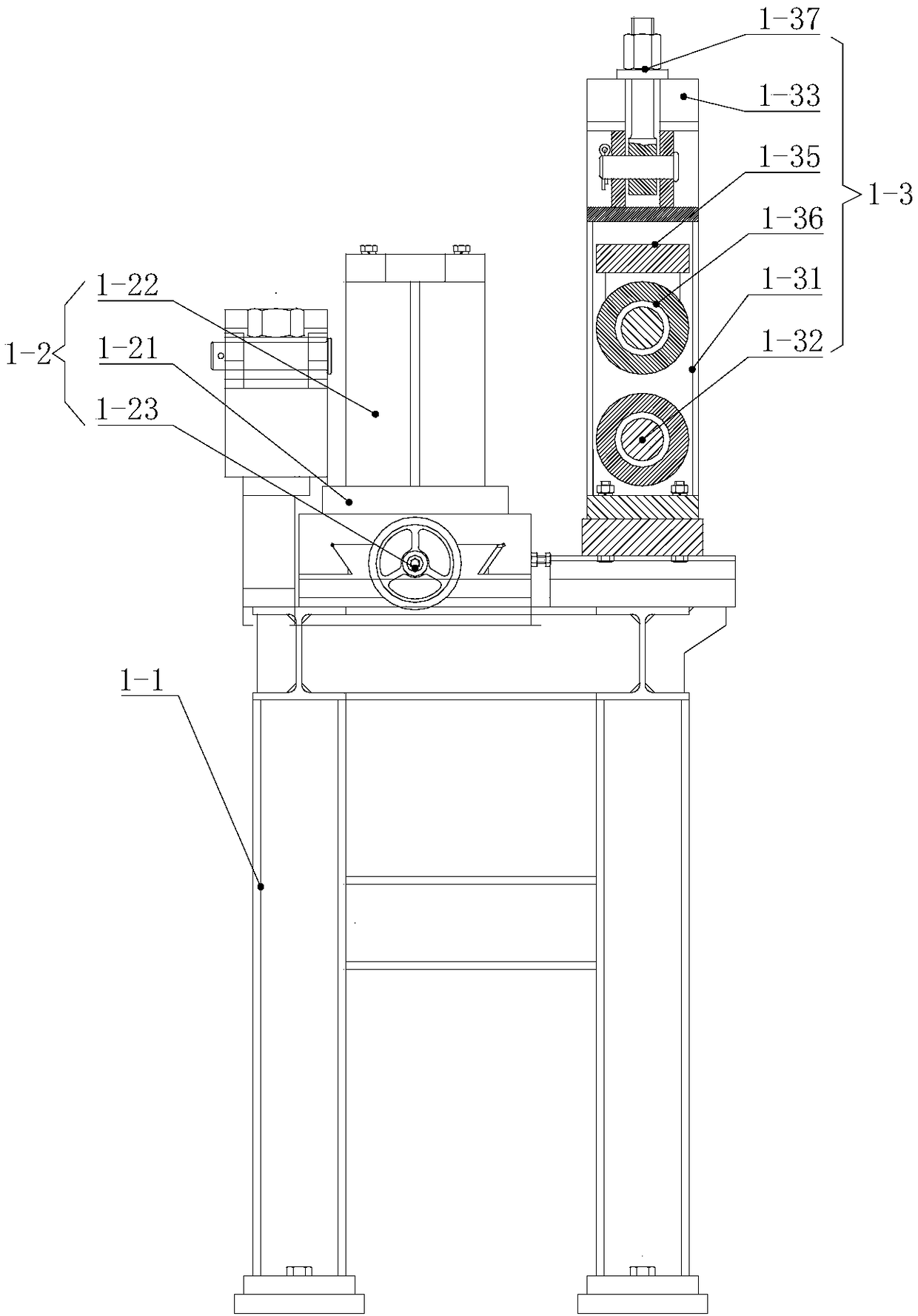

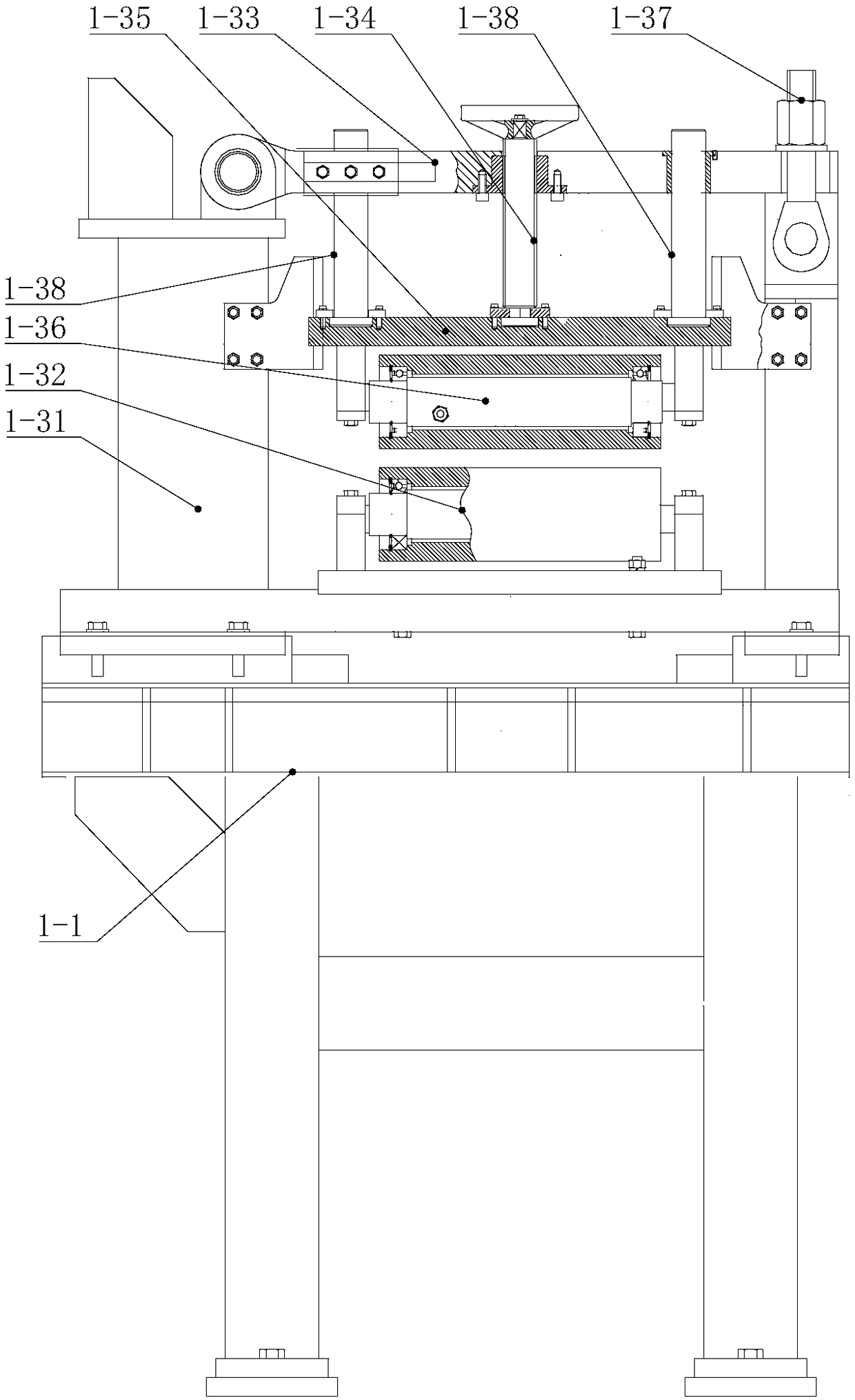

[0025] Such as figure 1 The coiled tubing service vehicle shown in the figure includes a car body 1, which can be a traditional truck, and a working platform 2 is provided on the car body 1, and a first support positioning device a1 and a straightening device are arranged on the working platform 2 in sequence 2. Welding pairing device 3, second support and positioning device a2, detection device 4, third support and positioning device a3, power generation equipment 5 and hydraulic station 6 are also installed on the car body 1. Among them, the working platform 2 can be lifted and rotated, and can be adapted according to the site requirements and the position of the coiled tubing, so as to ensure the smooth progress of on-site work for different sites. The first support and positioning device a1, the second support and positioning device a2 and the third support The positioning device a3 is used to limit the swing of the pipeline, so that the pipeline is transported on the serv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com