Manufacturing method of fabricated concrete light filler inner wall

A production method and concrete technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of cumbersome construction methods, a large number of manual cooperation, and long operation time, and achieve the effects of shortening the construction period, saving labor, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

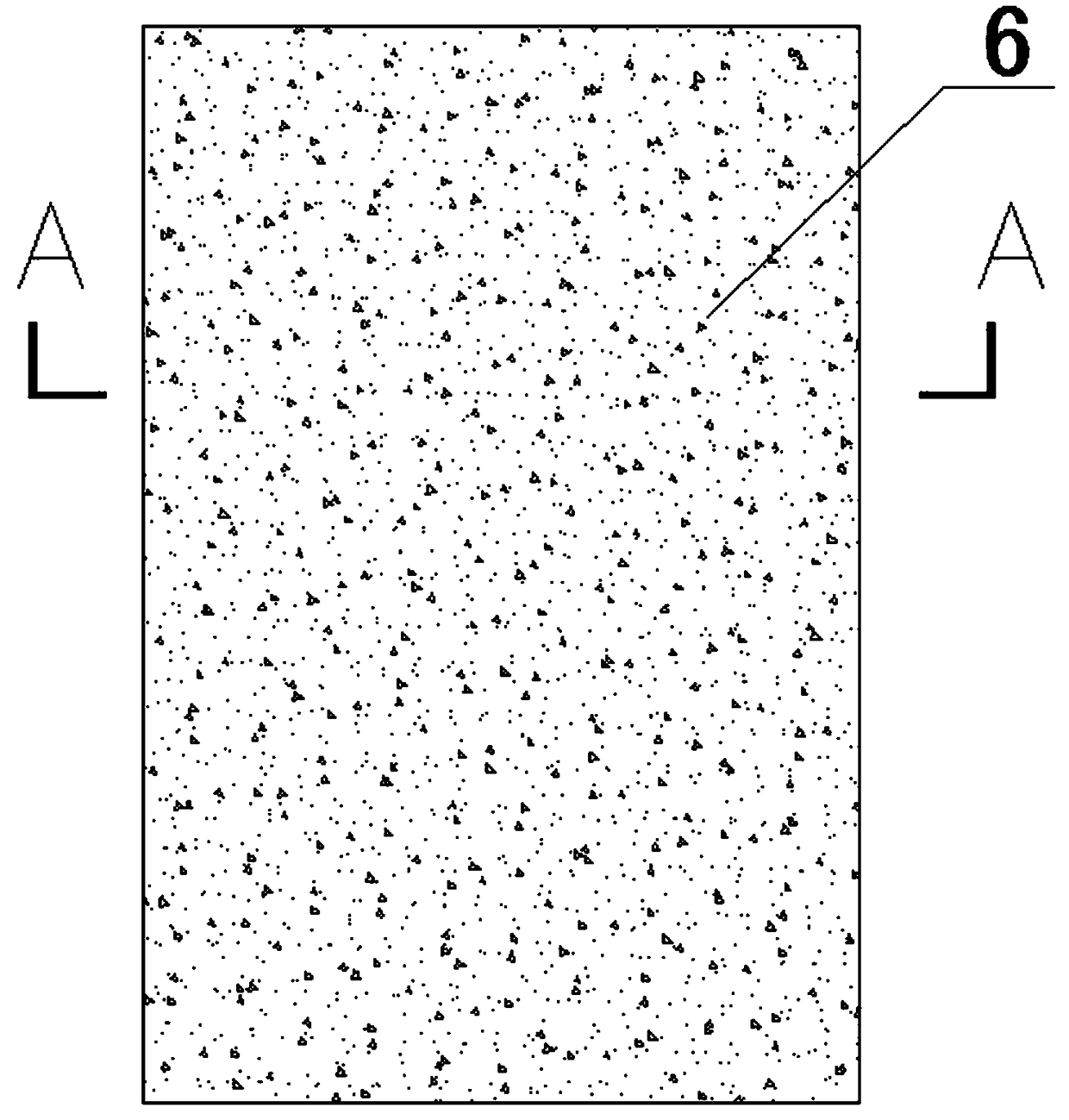

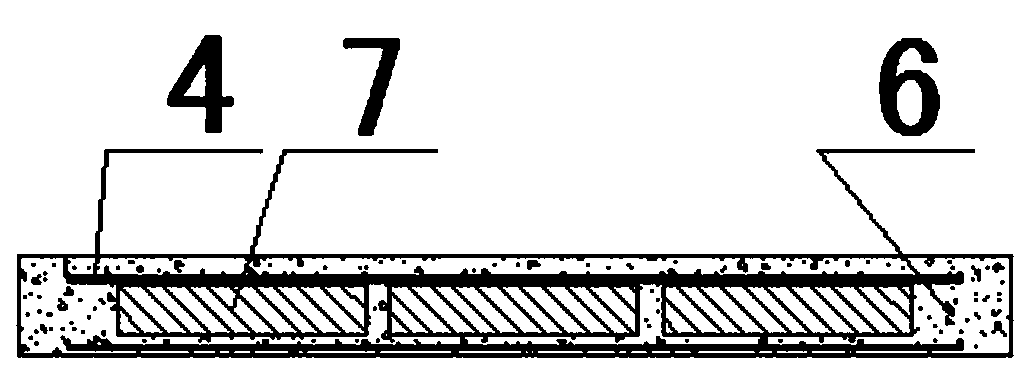

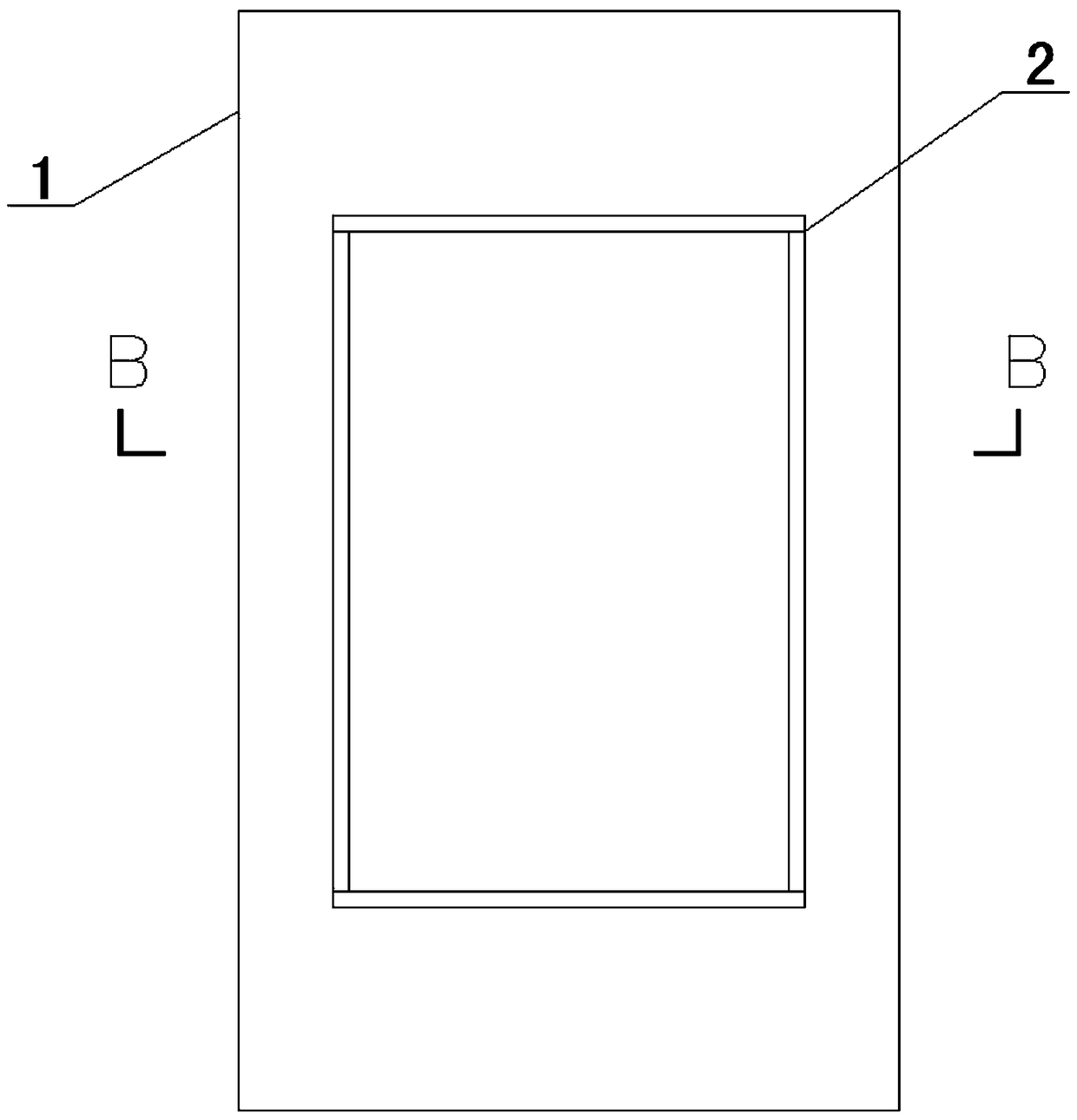

[0029] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , a method for fabricating a prefabricated concrete lightweight filled interior wall is carried out according to the following steps:

[0030] (1) First assemble the inner wall mold 2 on the operating platform 1 with bolts 3, and then reinforce the inner wall mold 2 corresponding to the bolt holes on the operating platform 1.

[0031] (2) Lay the reinforcement mesh 4 and place the block 5 under the reinforcement mesh 4 to leave a concrete protective layer for the reinforcement mesh 4.

[0032] (3) Then pour concrete 6, stop pouring until the concrete 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com