Novel writing brush with high ink absorption amount and manufacturing method of novel writing brush

A production method and ink volume technology, applied to other ink pens, ink pen repair, printing, etc., to achieve the effects of convenient replacement of pen tips, increased ink absorption, and increased ink storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

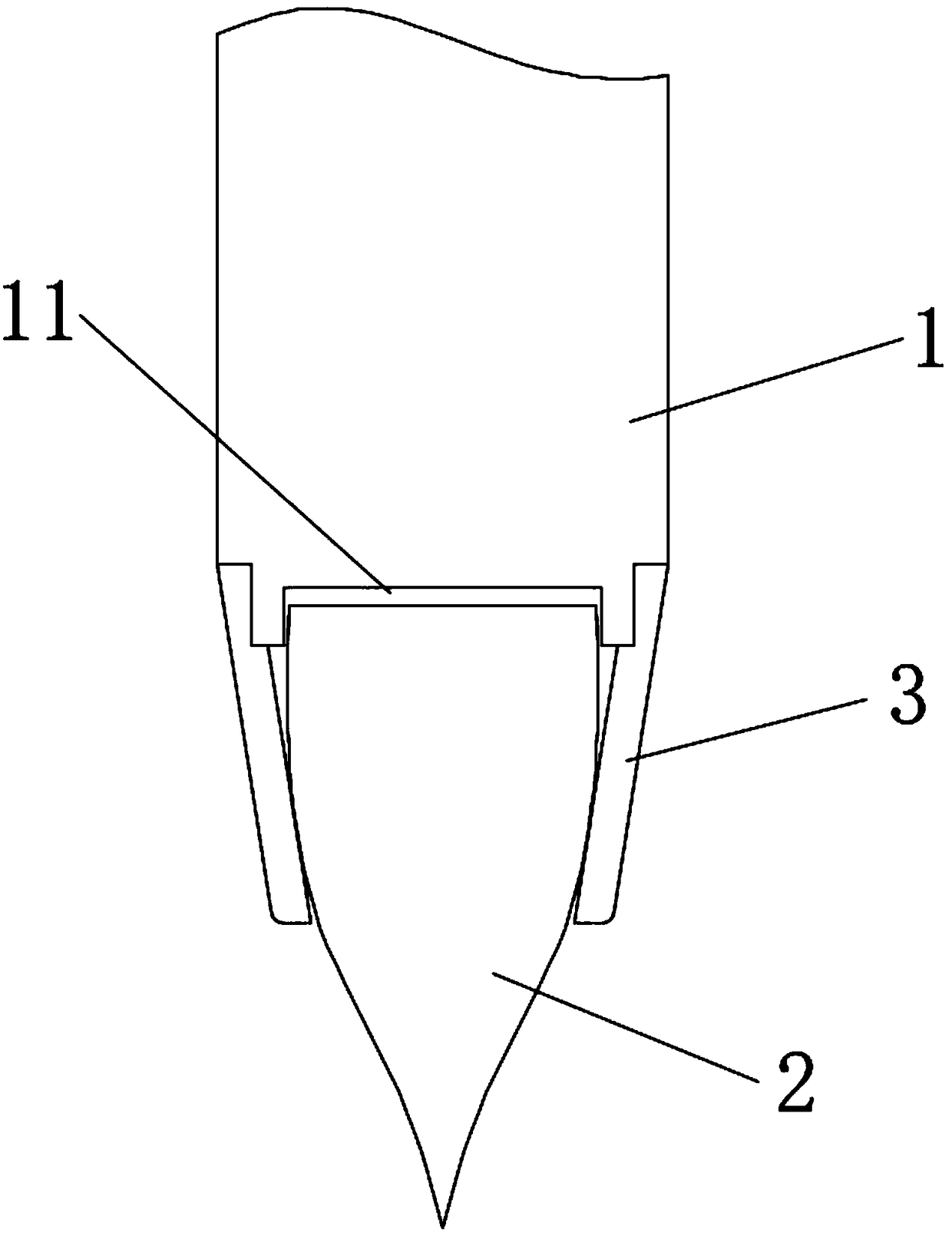

[0034] Such as Figure 1-2 As shown, a novel writing brush with a high ink absorption capacity comprises a penholder 1 and a groove 11 is provided on the end surface of one end of the penholder 1. A support sleeve 3 connected to the pen holder 1 is provided, the support sleeve 3 is a tapered sleeve gradually increasing from the pen head 2 to the pen holder 1, and the length of the pen head 2 exposed outside the support sleeve 3 accounts for 1% of the total length of the pen head 2 / 2~3 / 4. Generally, the diameter of nib 2 starts to shrink gradually from 1 / 4 length from the root position, so the support sleeve 3 needs to completely compress the nib 2, then it needs to start from the root of the nib 2 to its 1 / 4. The section length must be fully covered by the support sleeve 3, and in combination with actual use, the exposed length of the nib 2 is too short, which is not conducive to ink absorption.

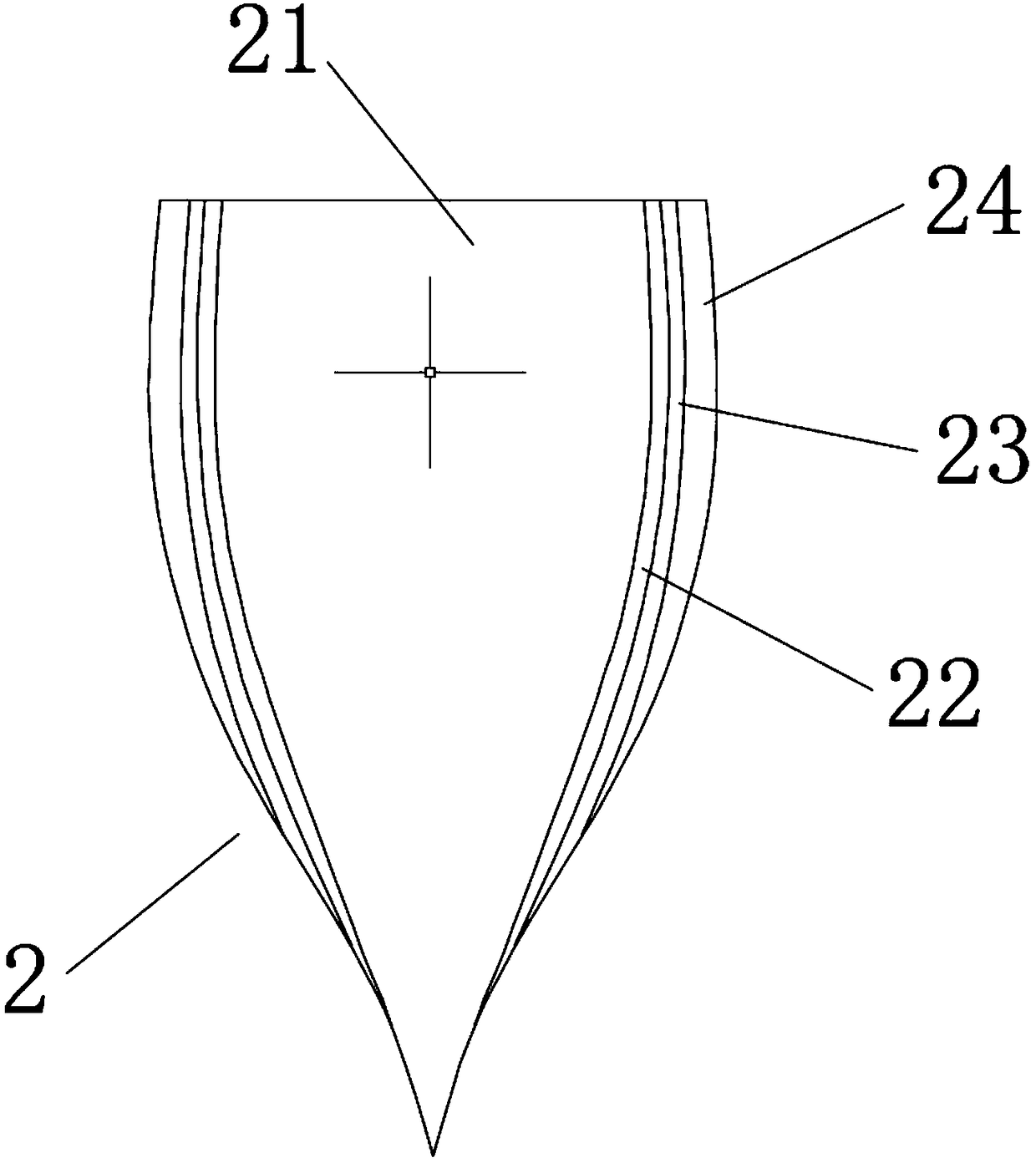

[0035] Specifically, the nib 2 includes a refill 21, and the refill 21 is coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com