Lifting platform electric control track continuous mechanism with fall-proof function

A lifting platform and functional technology, applied in the field of three-dimensional warehouses, can solve the problems of high production cost, high operating noise, easy damage of track wheels, etc., and achieve the effects of low production cost, practical installation and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

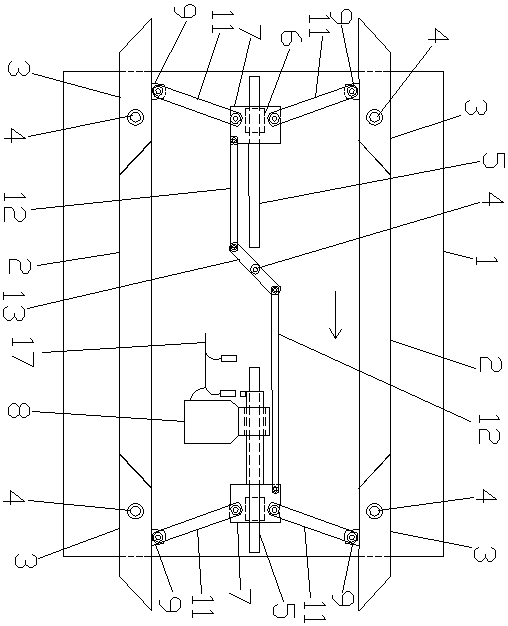

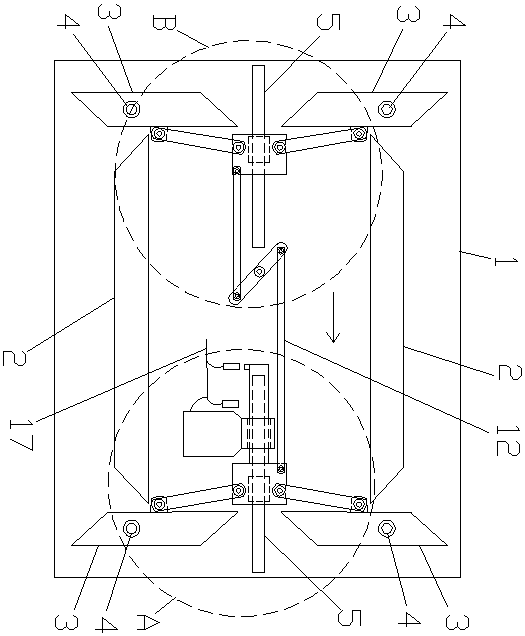

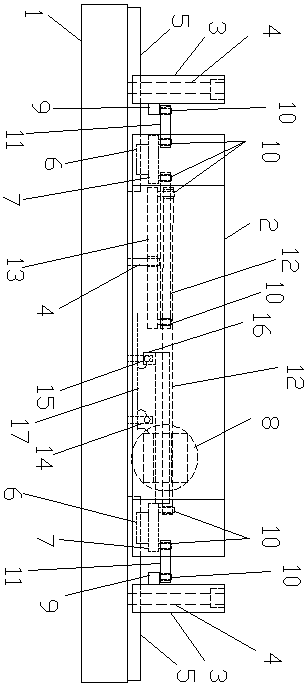

[0014] See attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 And attached Figure 5 , the direction of the arrow is forward, and the translation track 2, the pivot pin 4, the linear guide rail 5, the driving motor 8, the unfolding limit sensor 14 and the folding limit sensor 15 are respectively fixedly installed at the corresponding positions on the upper side of the lifting platform 1, and the pivot pin 4 Cooperate with the folding track 3 and the synchronous rod 13 to be movable respectively, respectively fix the driving end seat 9 at the corresponding position of the folding track 3, slide and set the slider 6 corresponding to the linear guide rail 5, and fix the driving end seat 9 on the upper side of the slider 6 respectively. Block 7, one end of the driver of the driving motor 8 is fixedly connected with the corresponding po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com