A preparation method of self-healing antibacterial microcapsule film based on host-guest interaction

A microcapsule, host-guest technology, which is applied to biocide-containing paints, coatings, anti-fouling/underwater coatings, etc., can solve the problems of reducing the service life of materials, reducing the cycle of food preservation, and re-injury of wounds, etc., to achieve Short time, good self-healing effect, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation method of the self-repairing antimicrobial microcapsule film based on host-guest interaction of the present invention comprises the following steps:

[0031] Step 1, successfully modifying ferrocene (Fc) on polyacrylic acid (PAA) branched chain to form PAA-Fc polymer;

[0032] Step 2, the microcapsules are attached with different concentrations of chloramphenicol;

[0033] Step 3, immerse the base material in the PAA-Fc solution for a period of time, take it out and rinse it with ultrapure water;

[0034] Step 4, immerse in β-cyclodextrin branched polyethyleneimine (β-CD-PEI) solution for a period of time, take it out and rinse with ultrapure water;

[0035] Step 5, immersing in the drug-loaded microcapsule solution for a period of time;

[0036] Step three, step four and step five are repeated to self-assemble layer by layer on the surface of the substrate to form a self-repairing antibacterial microcapsule host-guest film material.

Embodiment 1

[0038] 1) Mix 100 mg EDC and 30 mg NHS to obtain mixed solution II; add 80 mg Fc and 160 mg PAA to mixed solution II, and react at room temperature for 12 hours to obtain PAA-Fc polymer.

[0039] 2) Add 4 mg of chloramphenicol into the microcapsule solution, and ultrasonically vibrate for 5 minutes to obtain a microcapsule-coated chloramphenicol solution.

[0040] 3) Soak the cleaned glass sheet in 4mg / mL PAA-Fc solution for 15min, rinse with water, then immerse in 4mg / mLβ-CD-PEI solution for 15min, then rinse with water; soak in drug-loaded microcapsule solution for 15min, the above The steps were repeated for 30 cycles to prepare a self-healing antibacterial microcapsule host-guest film.

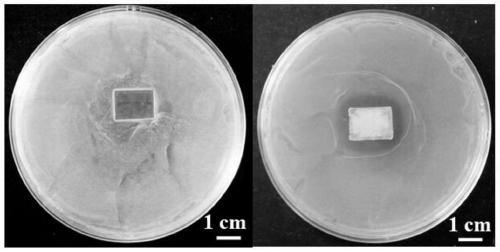

[0041] figure 1 It is the antibacterial efficacy figure of the nano-microcapsule host-guest film prepared in embodiment 1 to Escherichia coli.

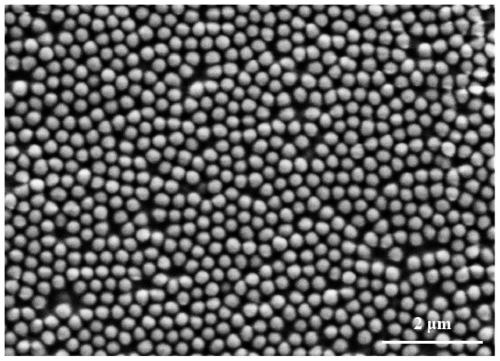

[0042] figure 2 It is the surface topography figure that embodiment 1 prepares nano-microcapsule host-guest film.

Embodiment 2

[0044] 1) Mix 113mg EDC and 32mg NHS to obtain a mixed solution II, add 90mg Fc and 175mg PAA into the mixed solution II, and react at room temperature for 16 hours to obtain a PAA-Fc polymer.

[0045] 2) Add 5 mg of chloramphenicol into the microcapsule solution, and ultrasonically vibrate for 6 minutes to obtain a microcapsule-coated chloramphenicol solution.

[0046] 3) Soak the cleaned glass piece in 5mg / mL PAA-Fc solution for 20min, rinse with water, then immerse in 5mg / mLβ-CD-PEI solution for 20min, rinse with water, soak in drug-loaded microcapsule solution for 20min, the above The steps were repeated for 25 cycles to prepare a self-healing antibacterial microcapsule host-guest film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com