Detecting tube for maintenance and detection of highway engineering foundation pile

A detection tube and engineering technology, which is applied in the field of detection tubes, can solve the problems that the side digging method is difficult to implement, it is difficult to popularize and apply, and it is difficult to achieve high stability in detection data collection, good data collection stability, temperature and air pressure. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings. The present invention adopts the products and materials bought in the market to refit or prepare according to conventional methods.

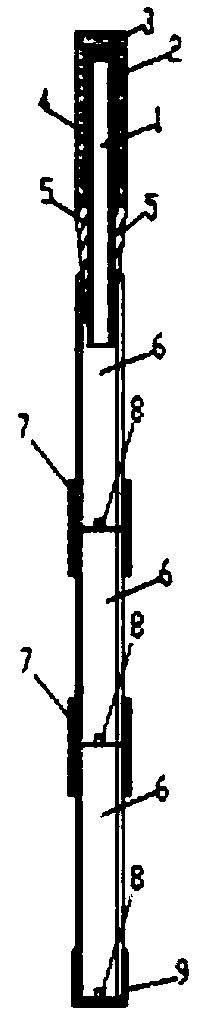

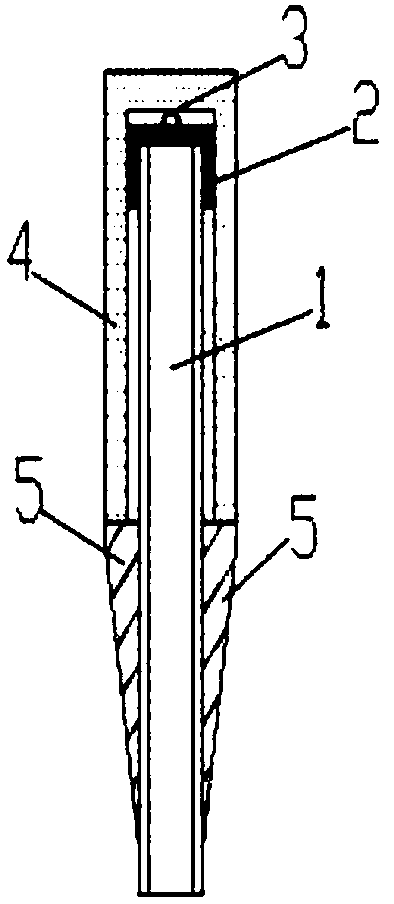

[0038] The detection tube for foundation pile maintenance detection of the present invention is composed of a nozzle joint part and a pipe body part; wherein:

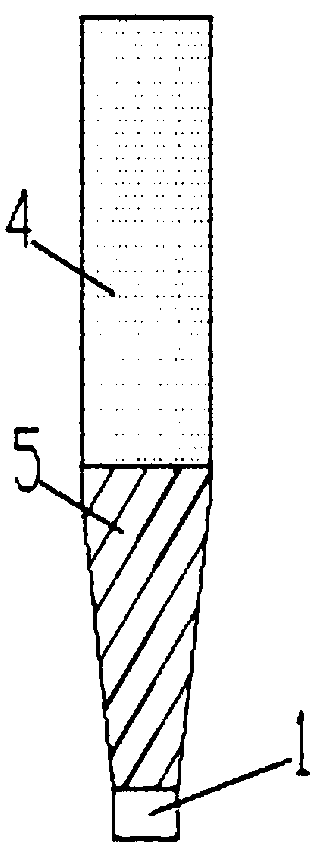

[0039] a. Nozzle joint parts include: rubber tube 1, sealing cover 2, sealing cover pull ring 3, pearl foam protective sleeve 4, single-sided rubber sleeve 5; the assembly method is: the top nozzle of rubber tube 1 is inserted into the sealing cover 2, the lower part of the sealing cover pull ring 3 is installed on the top of the sealing cover 2, the lower nozzle of the rubber tube 1 is inserted from the top of the single-sided wire protection rubber sleeve 5, and passes through the bottom of the single-side wire protection rubber sleeve 5, and the pearl foam protective s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com