Energy dissipation brace for composite steel plate

An energy-consuming support and steel plate technology, applied in building components, earthquake resistance, building types, etc., can solve the problems of reduced energy consumption capacity, loss of restraint and anti-buckling effect of constrained concrete, etc., to achieve sufficient energy consumption of the structure, reduce earthquake response, The effect of a large yield area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further illustrate the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but they should not be construed as limiting the protection scope of the present invention.

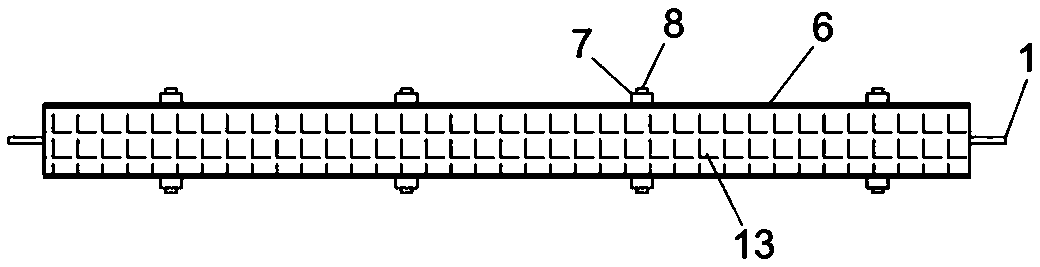

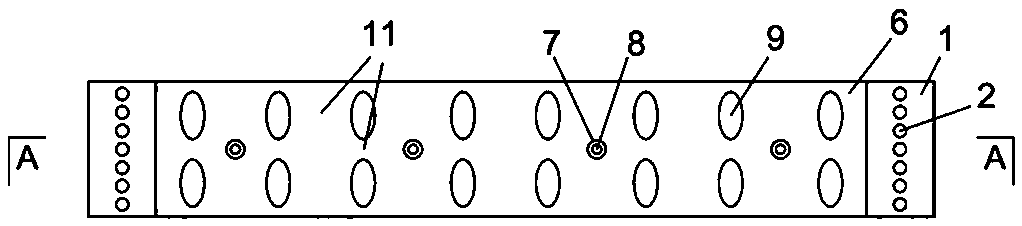

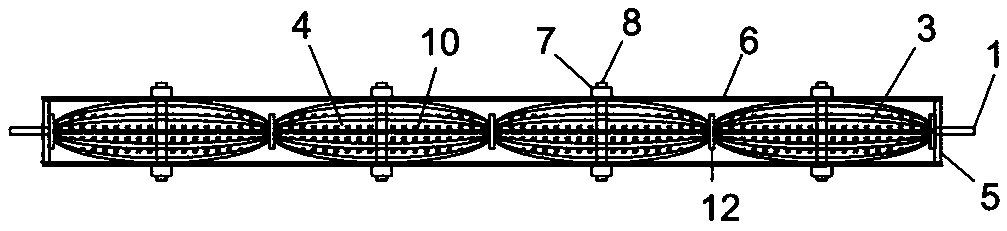

[0016] Such as Figure 1~Figure 3 As shown, a combined steel plate energy-dissipating support of the present invention includes a mounting plate 1, a screw hole 2, an arc-shaped energy-dissipating steel plate 3, an aluminum foam energy-dissipating material 4, a reinforced fixing plate 5, an energy-dissipating steel plate 6, and a lock nut 7 , Coordinating connecting steel bars 8, internally equipped with oval holes 9, main energy-dissipating steel plates 10, energy-dissipating ribs 11, steel hoops 12 and end energy-dissipating steel plates 13, in the structure of combined steel plate energy-dissipating supports, reinforced fixing plates 5, The energy-dissipating steel plate 6 and the end energy-dissipating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com