Temporary stabilizing structure for bottom bolted single-layer steel column installation and stabilizing method thereof

A stable structure, single-layer steel technology, applied in building construction, building material processing, construction, etc., can solve the problems of poor stability, small lateral stiffness, uneconomical, etc., and achieve the effect of maintaining stability and avoiding overturning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

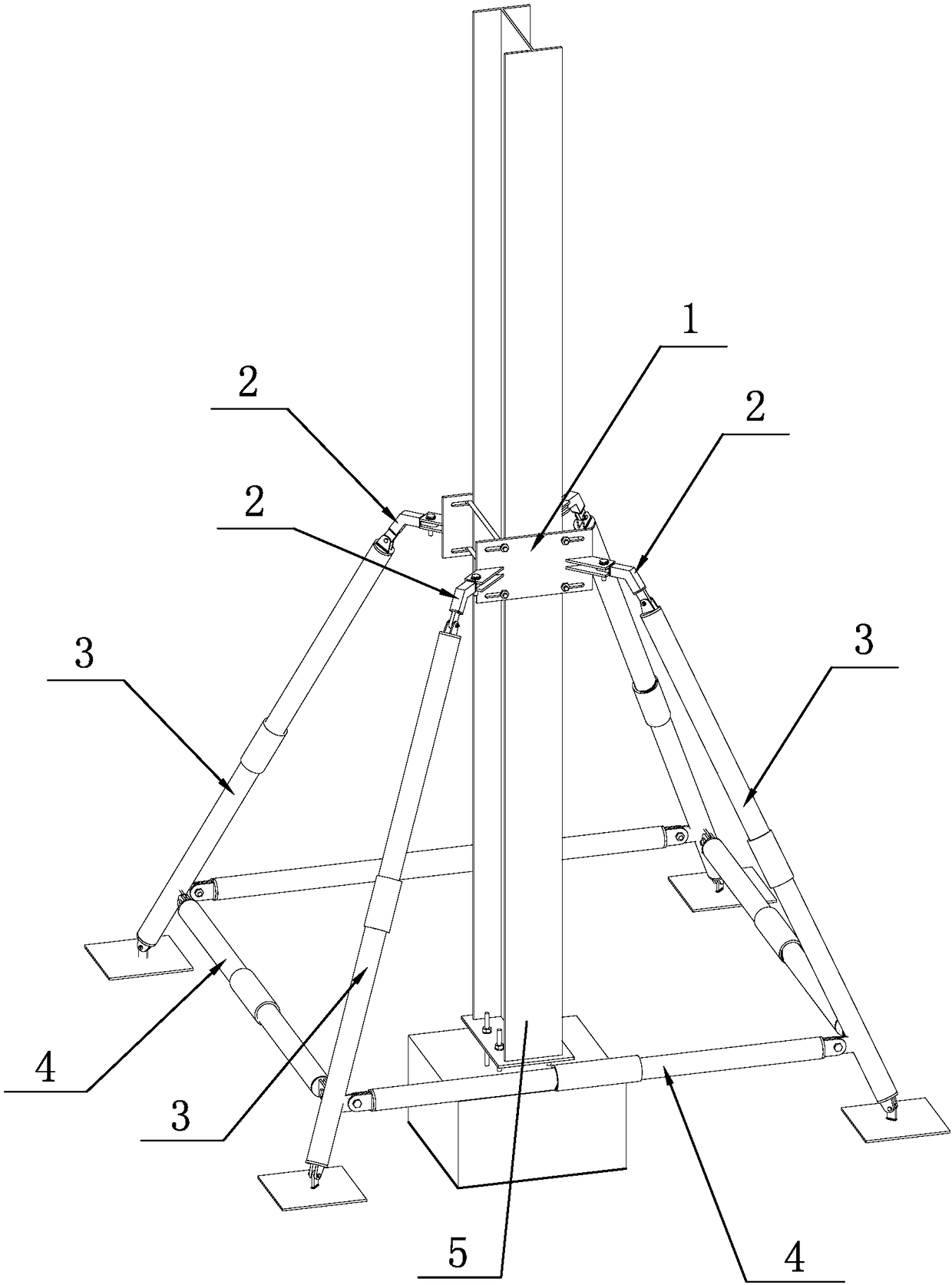

[0047] Such as Figure 1 to Figure 7 As shown, it is a temporary stabilizing structure for the installation of a bottom bolted single-layer steel column in the present invention, including an adjustable clamping device 1 , a rotatable connecting device 2 and a temporary stabilizing brace 3 .

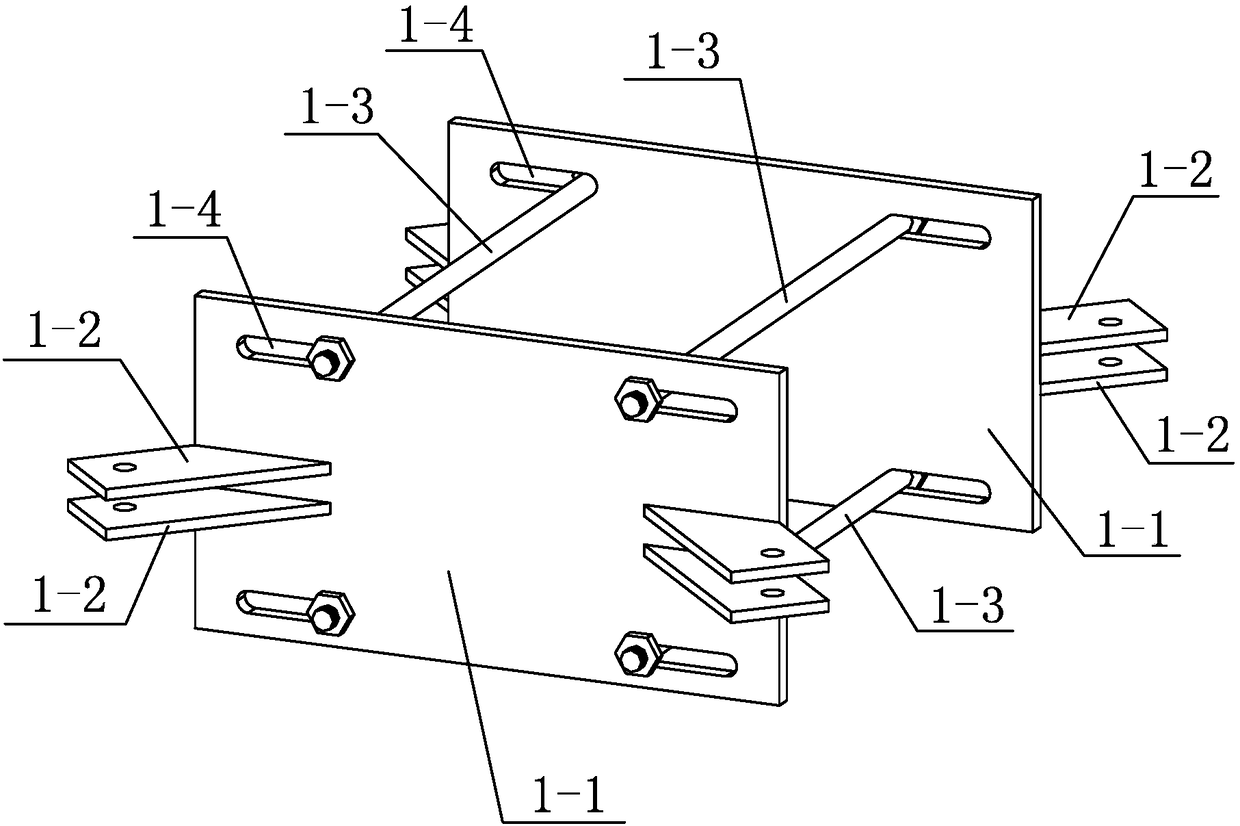

[0048] The adjustable tightening device 1 includes a tightening plate 1-1 and a tensioning screw 1-3, the tightening plate 1-1 is provided with an oblong hole 1-4, and the tensioning screw 1-3 penetrates into the oblong hole 1-4 . An ear plate 1-2 is provided on the outside of the clamping plate 1-1, and the rotatable connection device 2 is rotatably connected with the ear plate 1-2. The temporary stabilizing braces 3 are rotationally and fixedly connected to the rotatable connecting device 2 , and the bottom horizontal tie rods 4 are fixedly connected between the temporary stabilizing braces 3 .

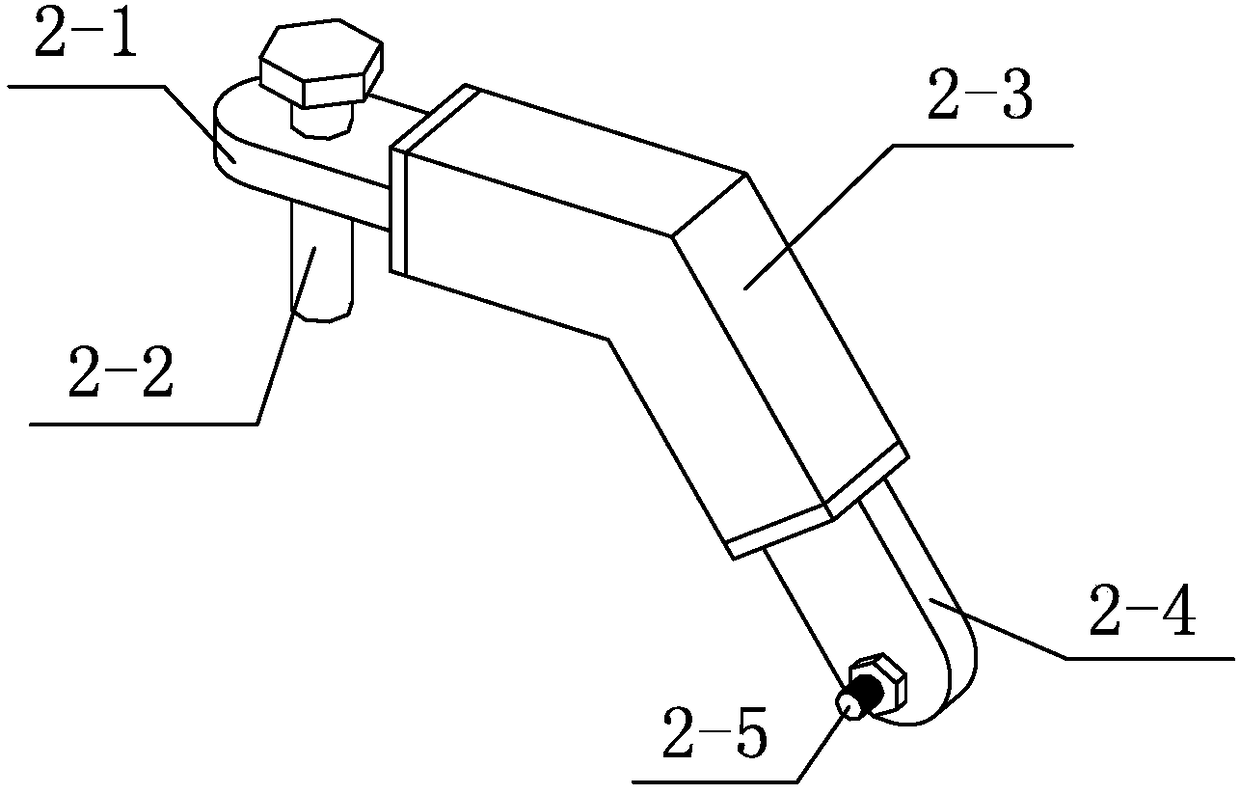

[0049] The rotatable connection device 2 includes a bending rod 2-3, the top of the bend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com