Solid phase microextraction sampling device and system

A sampling device and extraction technology, which are applied in the field of solid-phase microextraction sampling devices and their systems, can solve the problems affecting the accuracy of the SPME pretreatment technology, the application range, and limit the sample volume, and achieve the effects of reducing production costs and being quick to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

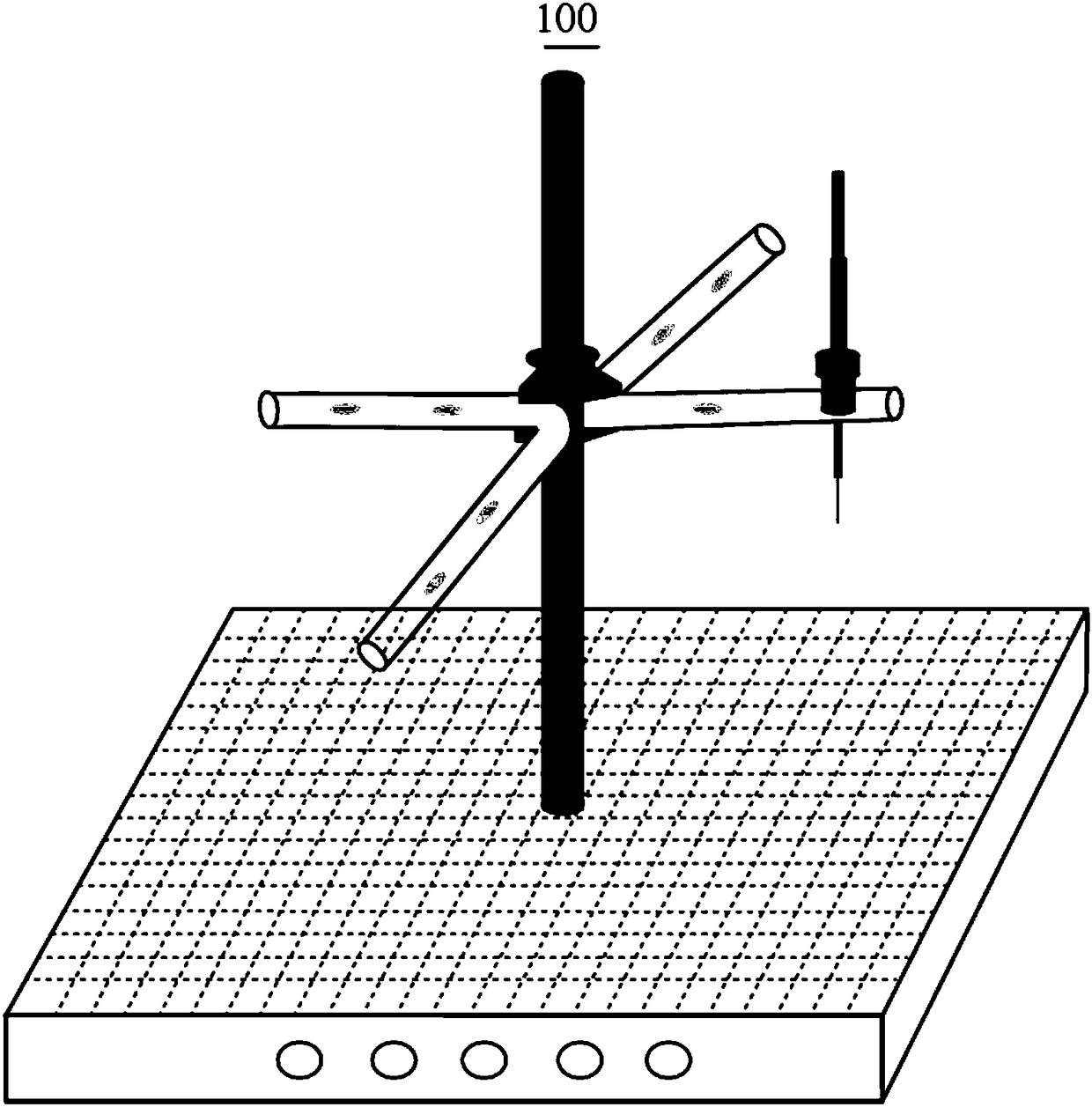

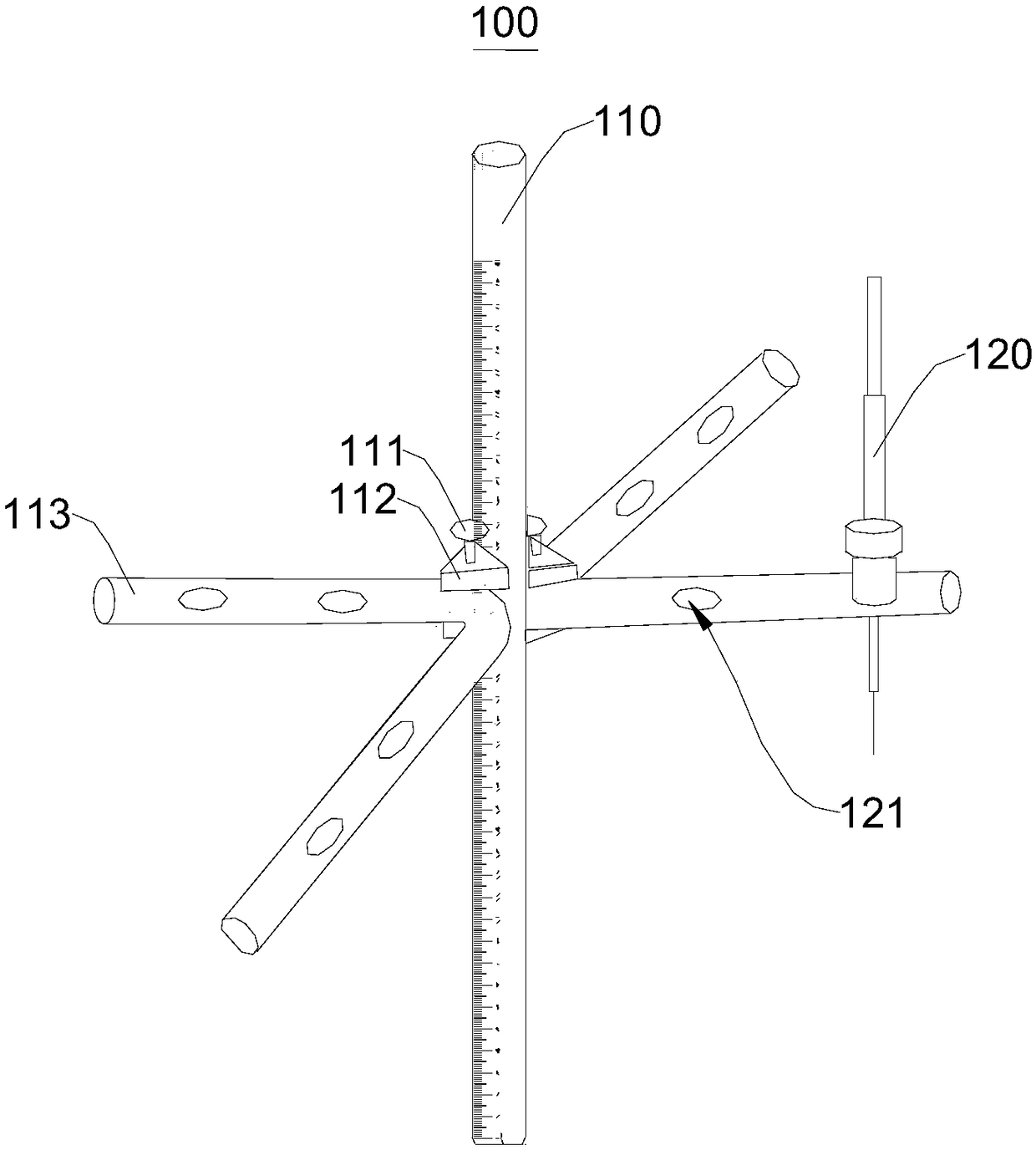

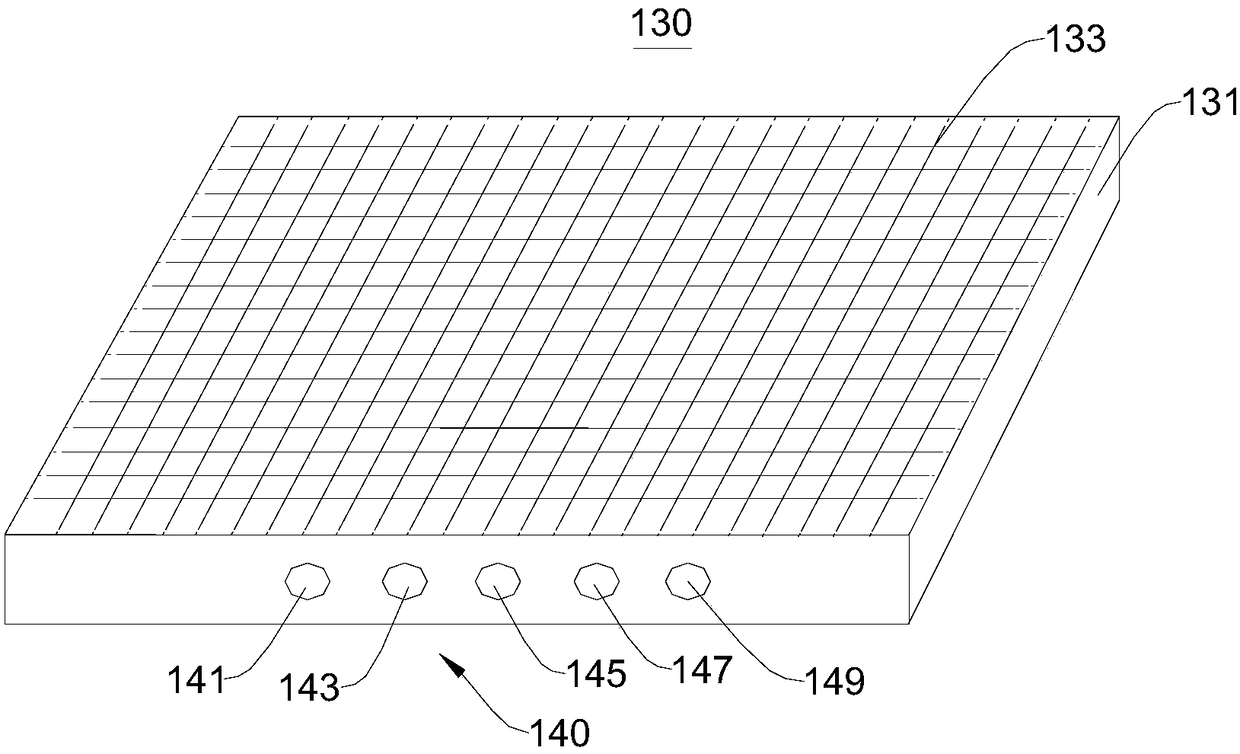

[0037] Please refer to figure 1 with figure 2, this embodiment provides a solid phase microextraction sampling device 100, including a bracket 110 and a magnetic stirring device 130, the bracket 110 is used to fix the handle 120 of the solid phase microextraction instrument. The bracket 110 is fixedly connected with the magnetic stirring device 130 , and the handle 120 of the solid phase microextractor is arranged on the bracket 110 . In this embodiment, the support 110 is perpendicular to the magnetic stirring device 130 , that is, the support 110 is perpendicular to the placement surface of the solid phase microextraction sampling device 100 . The bracket 110 in this embodiment is a cylindrical structure, and the bracket 110 is made of iron material. In other embodiments of the present invention, the bracket 110 may be a prismatic structure, and its material may be other materials such as aluminum alloy, which is not limited in the present invention.

[0038] The bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com