Computer-assisted screening method and system for motor vehicle VIN code rubbing film

A computer-aided, motor vehicle technology, applied in computer parts, computing, character and pattern recognition, etc., can solve problems such as difficult recognition, blurred characters, etc., to achieve the effect of strong applicability, lightening labor intensity, and improving screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

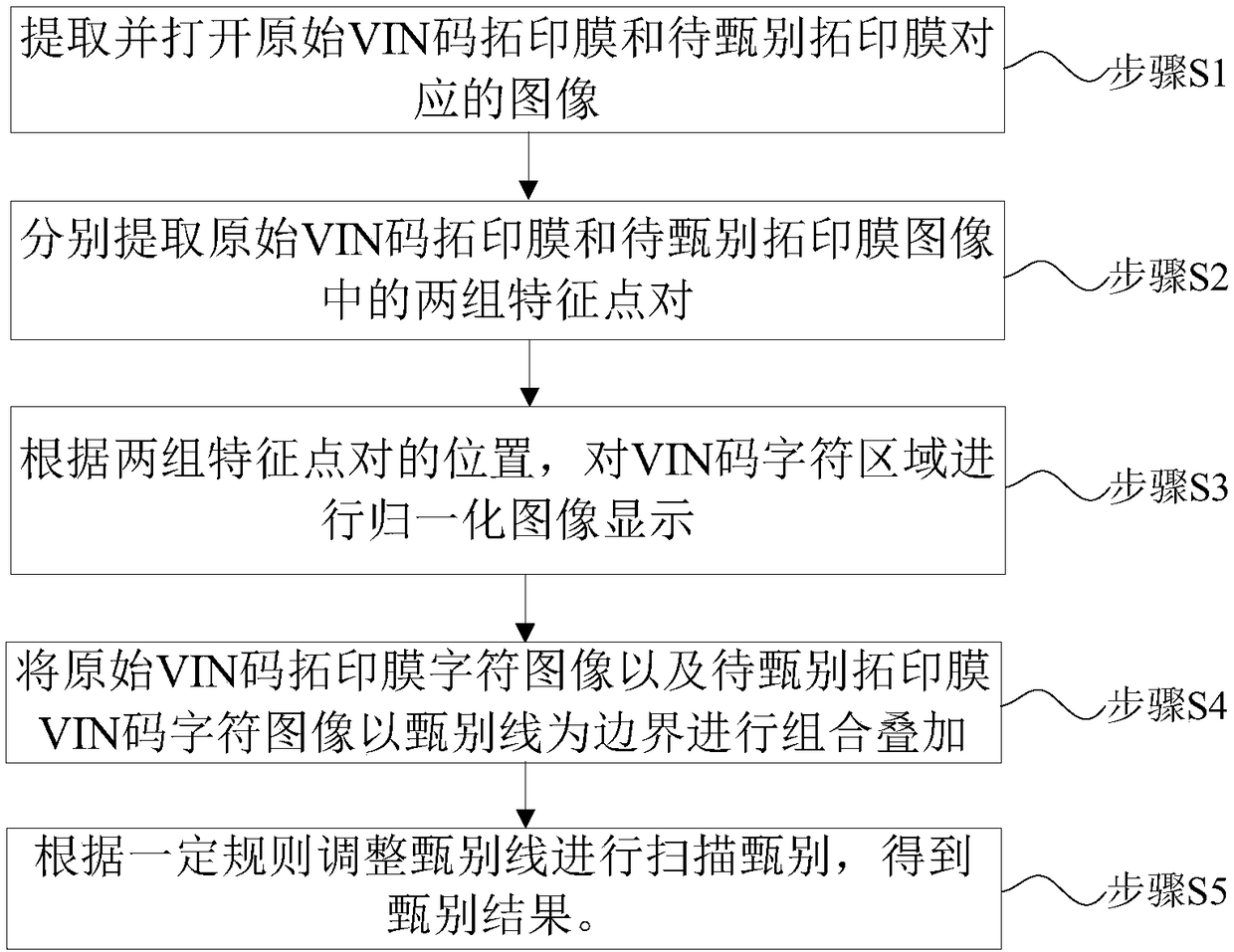

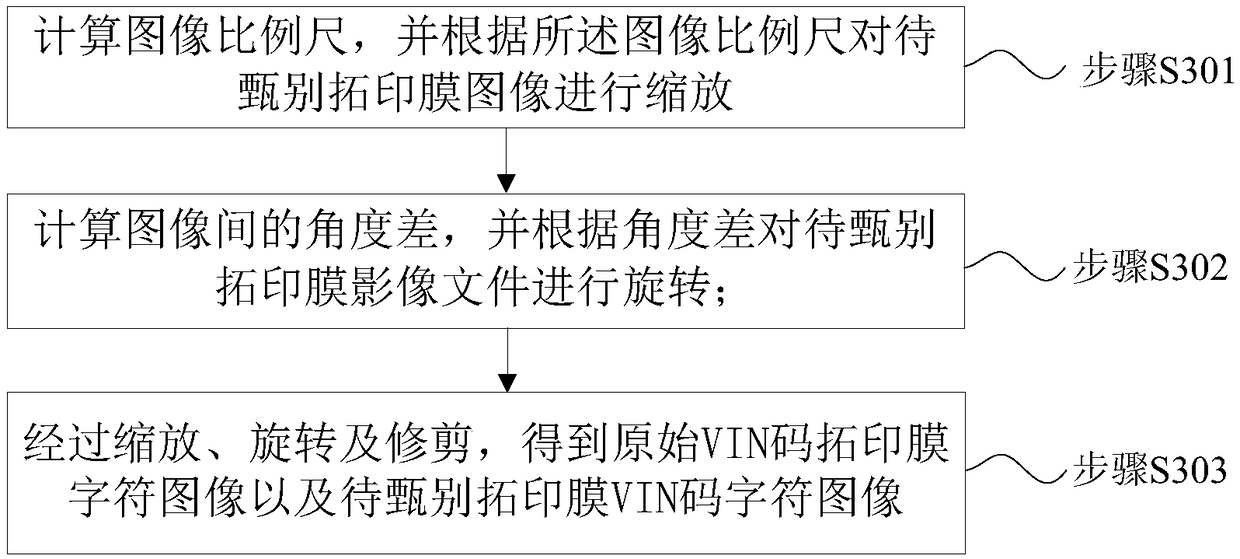

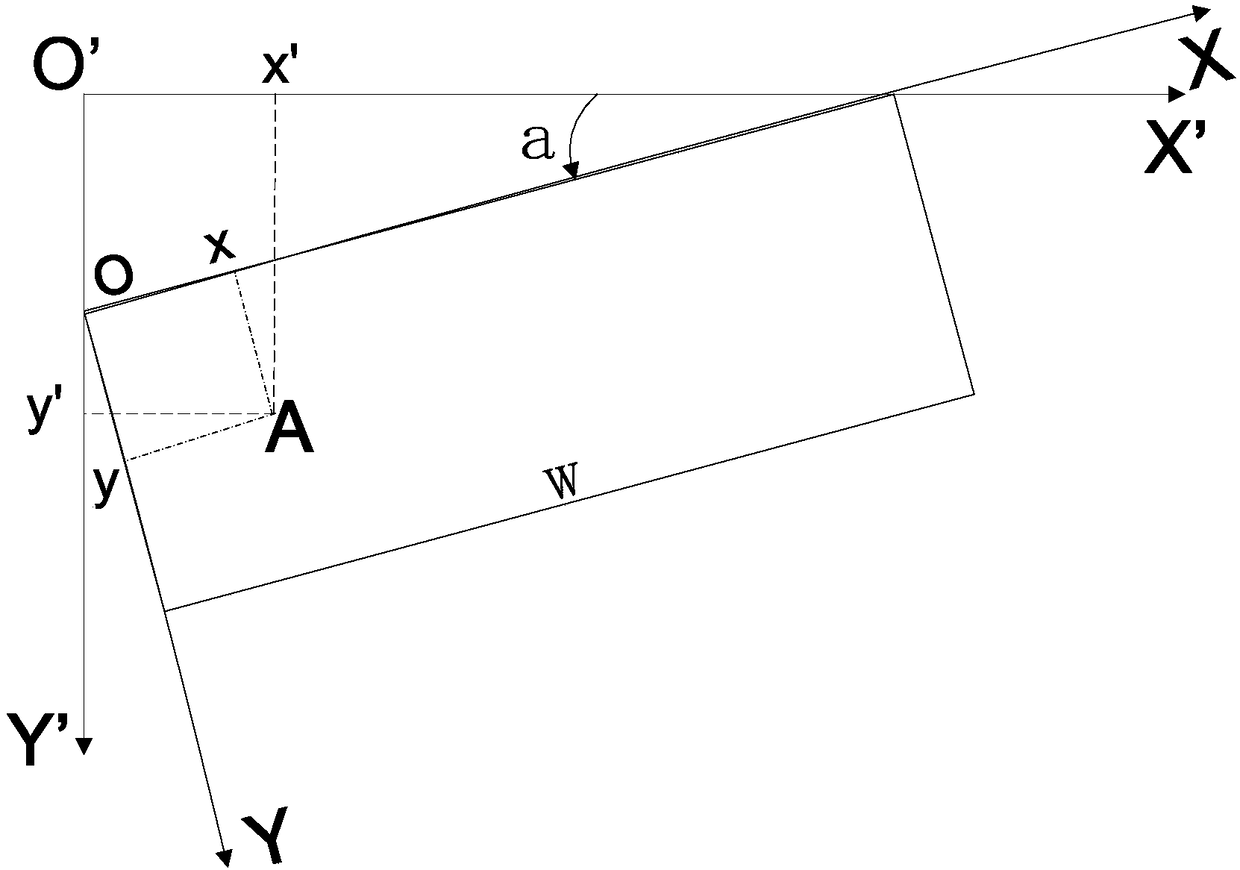

[0038] Such as figure 1 Shown: the invention discloses a computer-aided screening method for a motor vehicle VIN code rubbing film, comprising the following steps:

[0039] Step S1, extracting files, scanning the original VIN code rubbing film and the rubbing film to be screened and saving them as image files in the same format, the system extracts and opens the original VIN code rubbing film image and the rubbing film image to be screened;

[0040] Step S2, select two groups of feature point pairs, extract the original VIN code rubbing film image and the VIN code feature points located in the same position of the VIN code character area in the original VIN code r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com