Reliability-based opportunity preventive maintenance optimization model for key components of trains

An optimization model and preventive technology, applied in forecasting, instrumentation, data processing applications, etc., can solve problems such as high fixed maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be described in detail below in combination with specific embodiments.

[0080] Case Analysis

[0081] (1) Working condition parameters

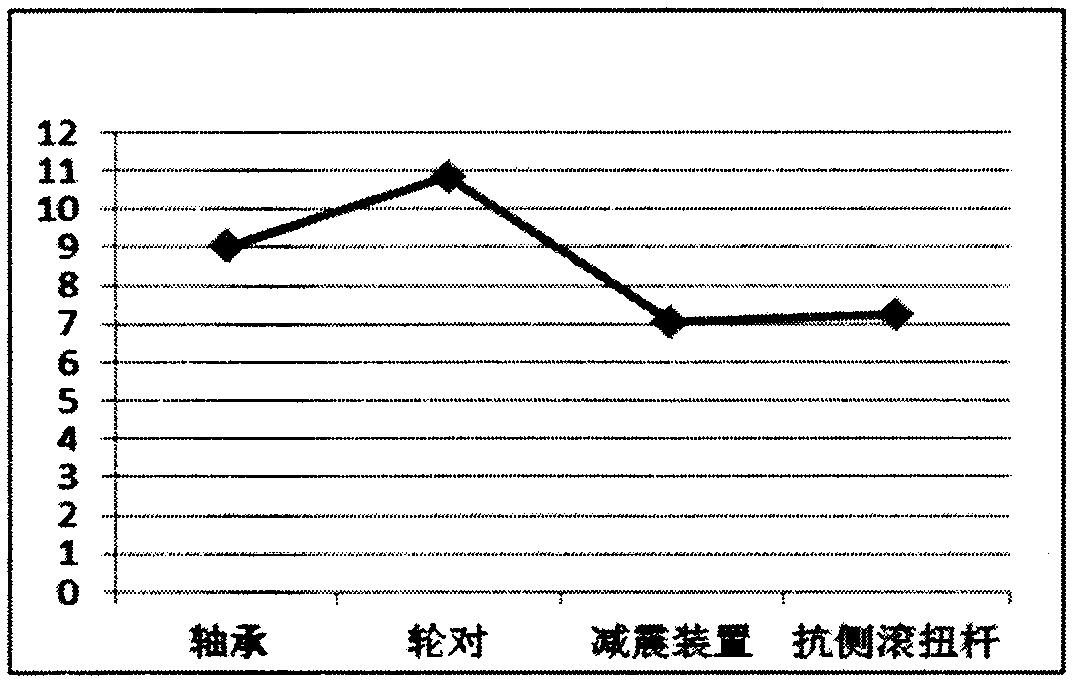

[0082] In this embodiment, the four components of the key components of the train bogie, the bearing, the wheel set, the shock absorber, and the anti-rolling torsion bar, are taken as an example. In order to check the calculation needs, the three-month inspection is taken as a maintenance cycle, that is, T=90d, assuming that the maintenance cycle The number of fault repairs in Z = 6. Table 1 shows the Weibull distribution parameters and maintenance costs of some key components of B-type trains of a certain subway company. Among them, various maintenance costs are expressed as the average cost of one maintenance of the same type of parts of all bogies of a single train.

[0083] Table 1

[0084]

[0085] (2) Optimization method

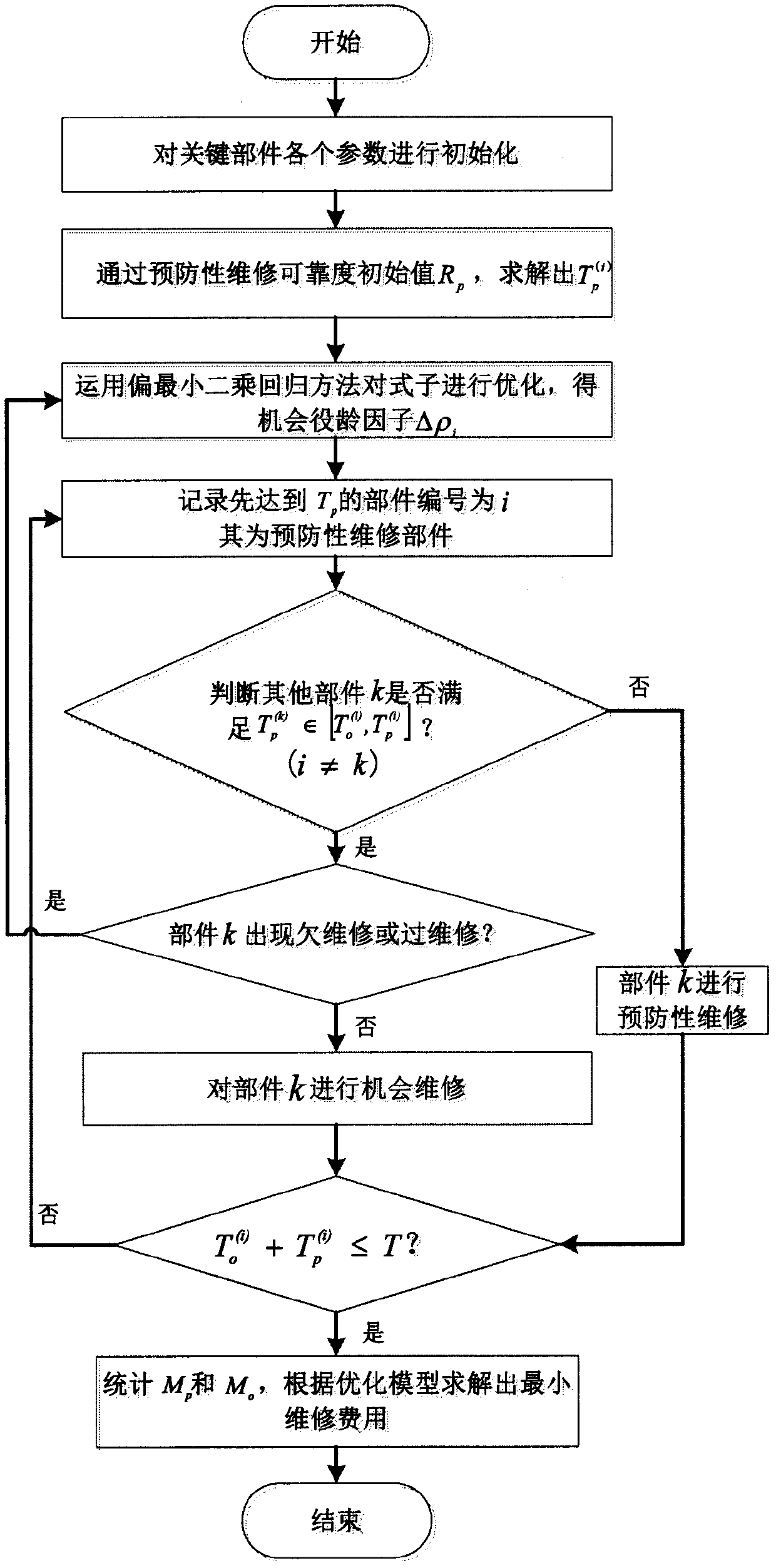

[0086] A reliability-based opportunistic preventive maintenance optimizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com