Workshop multi-row layout modeling and solving method

A layout method and layout technology, applied in the field of modeling and solving of multi-line layouts in workshops, can solve the problems of low model approximation, horizontal and vertical placement of facilities layout of unequal areas, regional spacing and main roads, mathematical models Problems such as large differences with the actual physical model to achieve the effect of improving the search ability and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

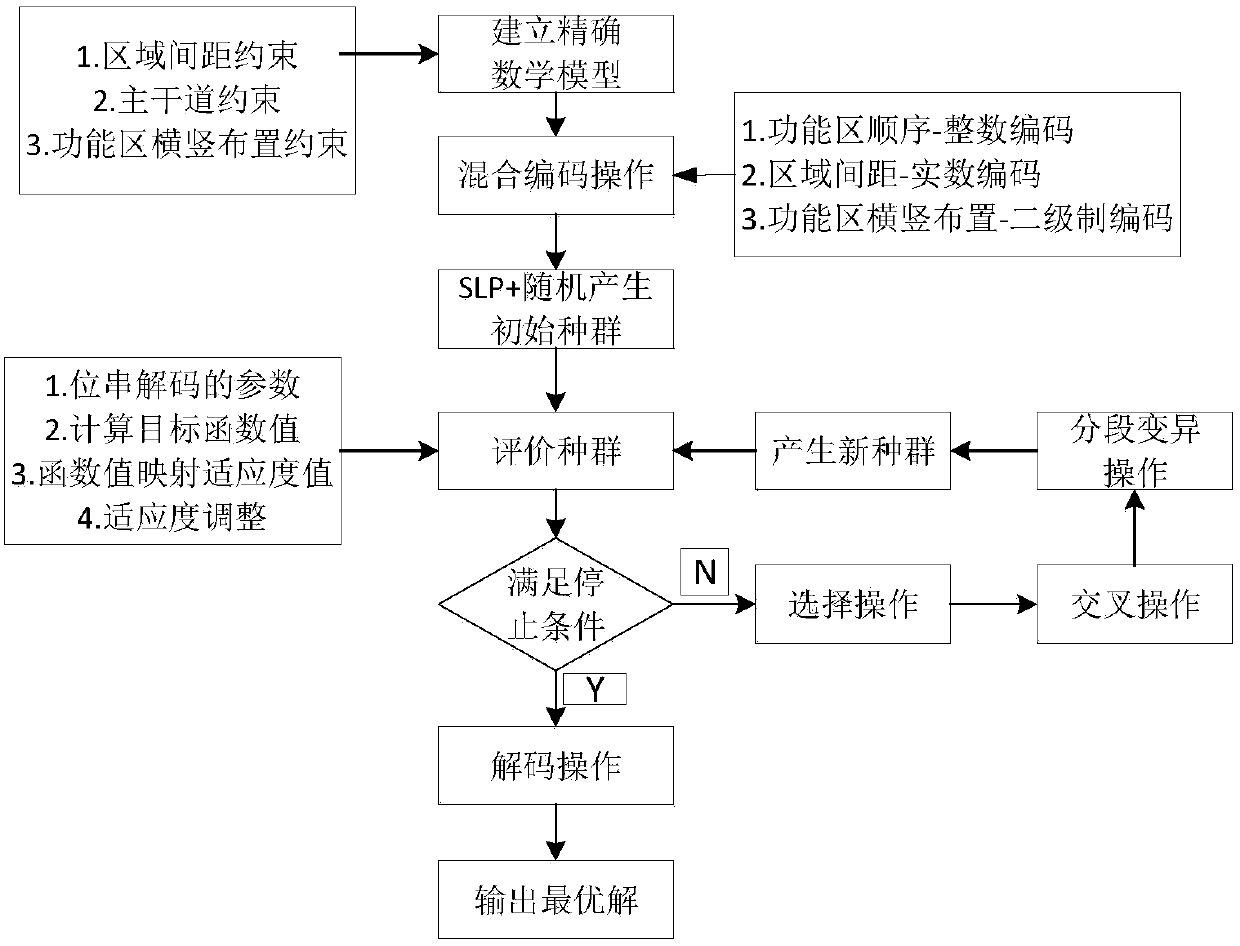

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. A method for modeling and solving a workshop multi-row layout of the present invention comprises the following steps:

[0049] Step 1: MMIP-based modeling of overall workshop layout

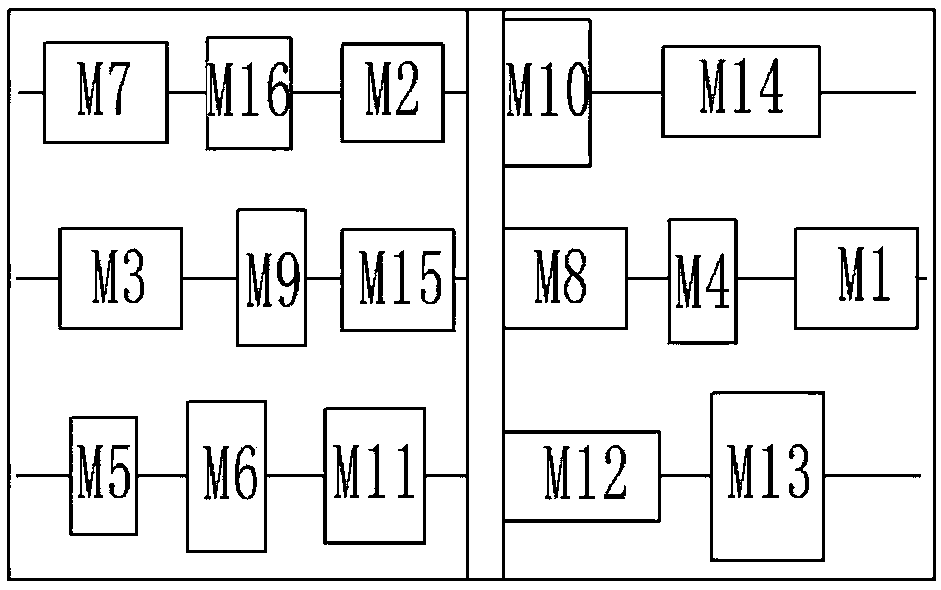

[0050] In order to reduce the calculation scale, the paper "Research on Multi-level Layout and Optimization of Aircraft Structural Parts Processing Workshop" (Chen Chunpeng, Wang Ruoxin, Ding Guofu, Zhang Jian. Manufacturing Automation, 2017,39(02):138-141.) The three-tier layout method. Among them, the third-level layout problem, that is, the overall layout of the workshop with unequal functional areas, is the most complicated one. According to the multiple constraints and rules of the site, the layout constructs an optimization function and solves it to meet the minimum logistics flow, the shortest logistics path and other indicators, and obtain the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com