Thin film transistor, array substrate and display apparatus

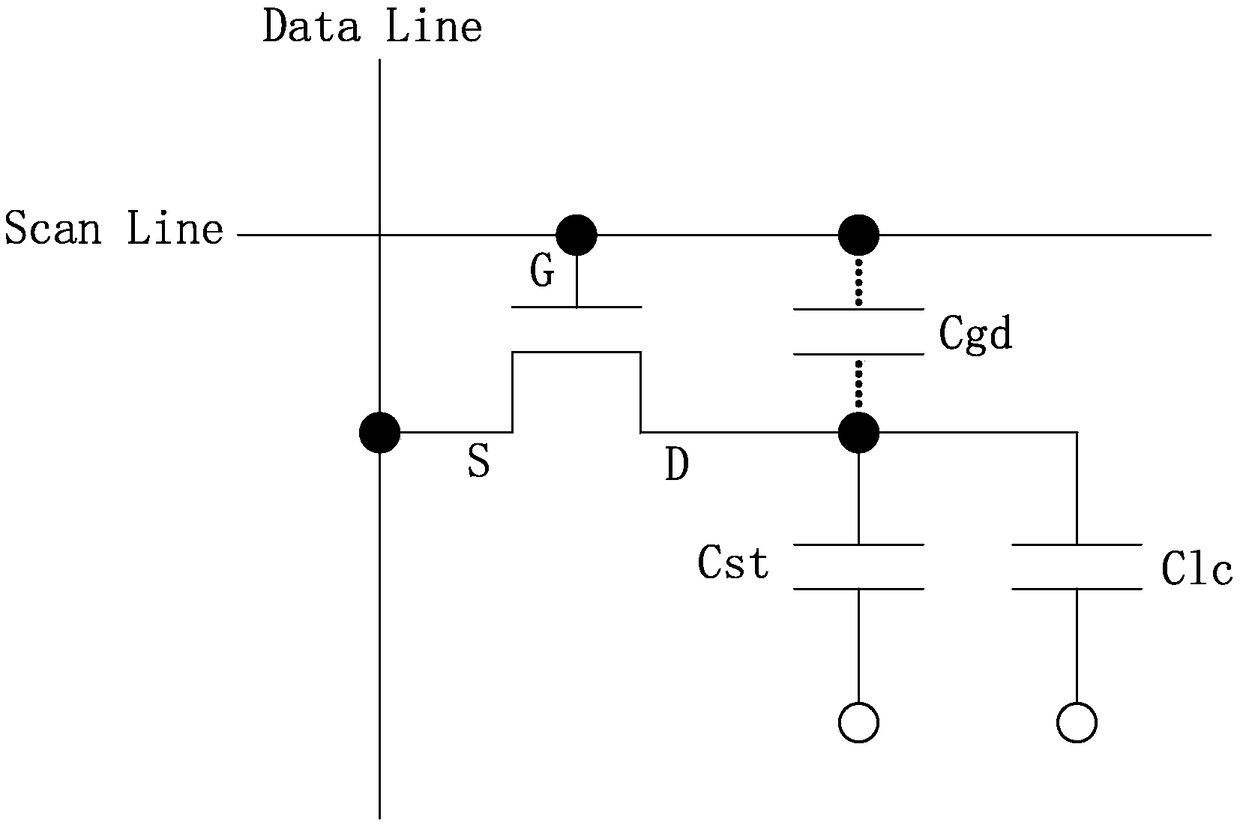

A technology of thin film transistors and transparent substrates, applied in transistors, electric solid state devices, semiconductor devices, etc., can solve the problems of lowering the display quality of display devices, flickering of display images, afterimages and grayscale confusion, etc., so as to improve display quality and reduce feedback. The effect of the voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

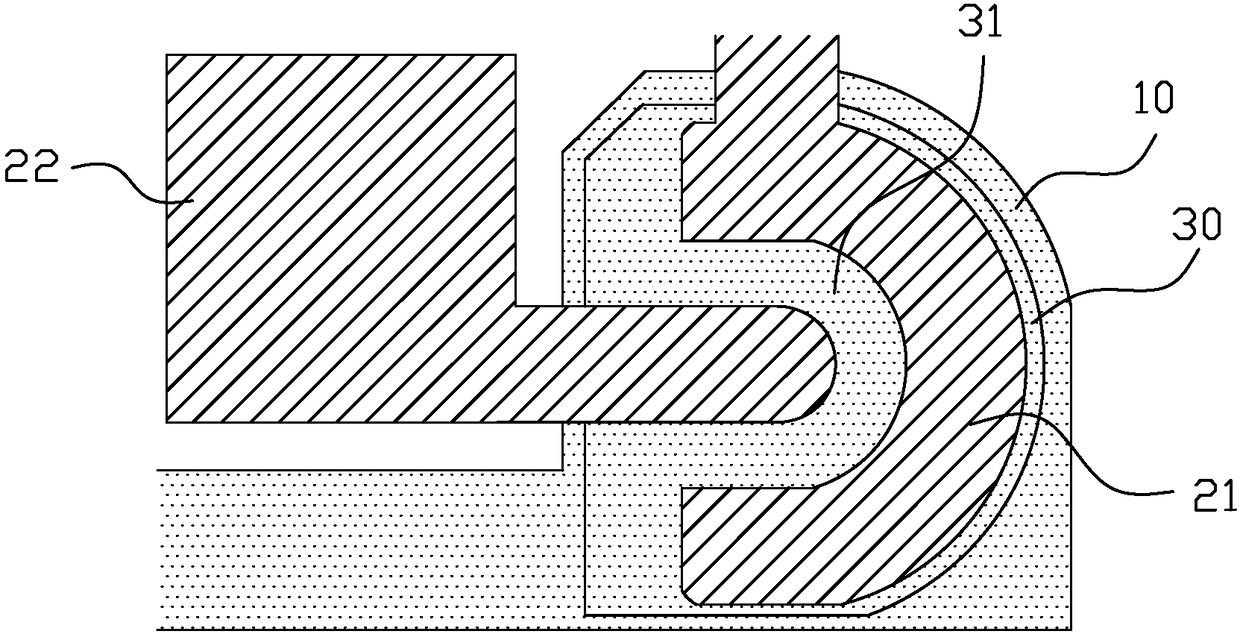

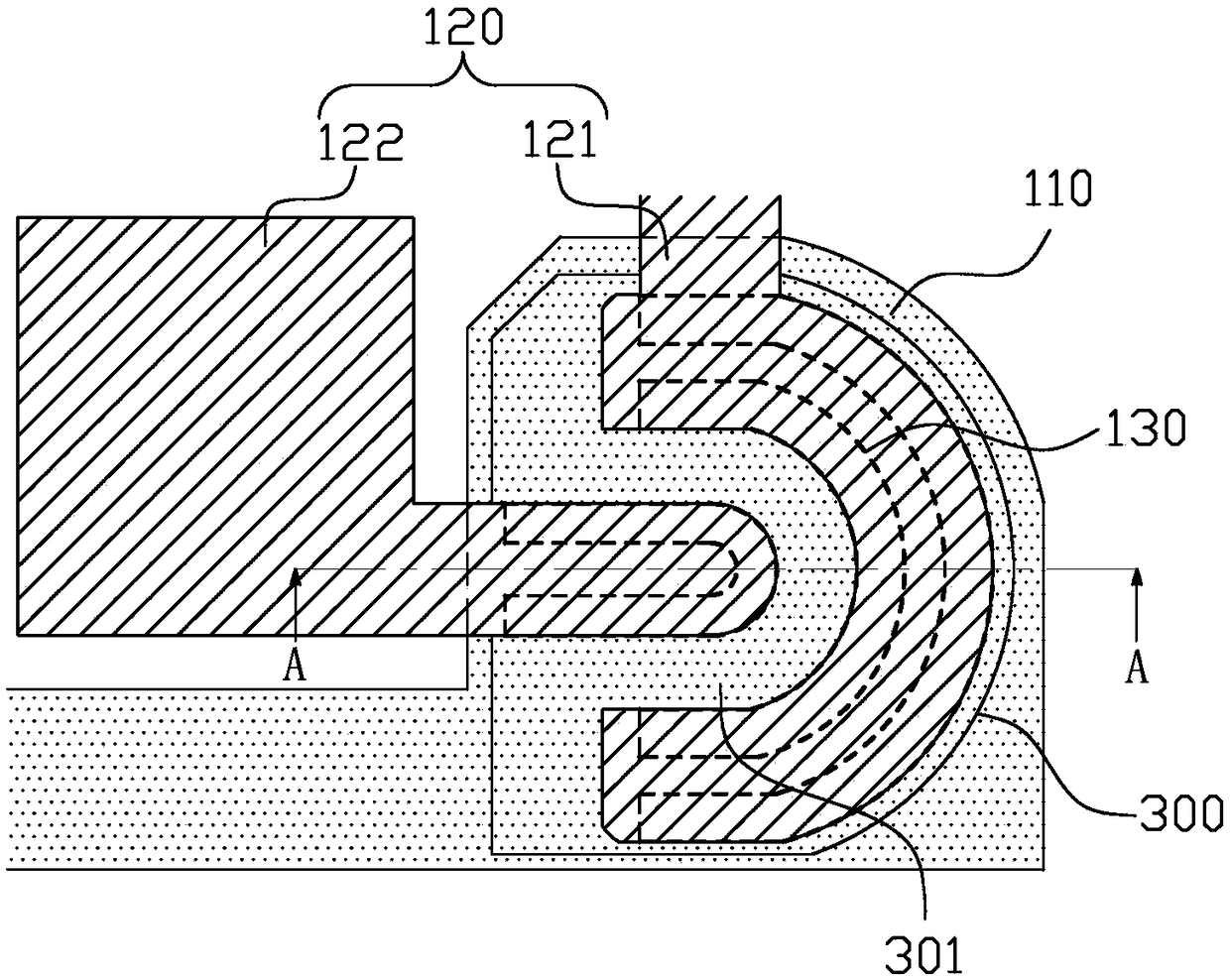

[0035] Please refer to Figure 3 to Figure 6 The thin film transistor provided by the first embodiment of the present invention includes a gate 110 , a source-drain metal layer 120 and a semiconductor layer 300 disposed on a transparent substrate 100 . Wherein, the gate 110 is arranged on the transparent substrate 100; the gate insulating layer 101 is also provided on the transparent substrate 100 to cover the gate 110; the semiconductor layer 300 is arranged on the gate insulating layer 101 and is located above the gate 110; The drain metal layer 120 is disposed on the semiconductor layer 300, including a source electrode 121 and a drain electrode 122. The source electrode 121 and the drain electrode 122 are separated from each other and are in contact with the semiconductor layer 300. The semiconductor layer 300 is provided with a channel 301, and the channel 301 is provided with between the source 121 and the drain 122 .

[0036]The source 121 is a "U"-shaped or "C"-shaped...

no. 2 example

[0047] Please refer to Figure 7 to Figure 10 , The thin film transistor provided by the second embodiment of the present invention includes a gate 110 , a source-drain metal layer 120 and a semiconductor layer 300 disposed on a transparent substrate 100 . Wherein, the gate 110 is arranged on the transparent substrate 100; the gate insulating layer 101 is also provided on the transparent substrate 100 to cover the gate 110; the semiconductor layer 300 is arranged on the gate insulating layer 101 and is located above the gate 110; The drain metal layer 120 is disposed on the semiconductor layer 300, including a source electrode 121 and a drain electrode 122. The source electrode 121 and the drain electrode 122 are separated from each other and are in contact with the semiconductor layer 300. The semiconductor layer 300 is provided with a channel 301, and the channel 301 is provided with between the source 121 and the drain 122 .

[0048] The source 121 is a "U"-shaped or "C"-s...

no. 3 example

[0059] Please refer to Figure 11 to Figure 14 , The thin film transistor provided by the third embodiment of the present invention includes a gate 110 , a source-drain metal layer 120 and a semiconductor layer 300 disposed on a transparent substrate 100 . Wherein, the gate 110 is arranged on the transparent substrate 100; the gate insulating layer 101 is also provided on the transparent substrate 100 to cover the gate 110; the semiconductor layer 300 is arranged on the gate insulating layer 101 and is located above the gate 110; The drain metal layer 120 is disposed on the semiconductor layer 300, including a source electrode 121 and a drain electrode 122. The source electrode 121 and the drain electrode 122 are separated from each other and are in contact with the semiconductor layer 300. The semiconductor layer 300 is provided with a channel 301, and the channel 301 is provided with between the source 121 and the drain 122 .

[0060] The source 121 is a "U"-shaped or "C"-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com