Universal stack banding mold for thermal battery

A thermal battery and stack technology, applied in the direction of primary battery to battery grouping, can solve the problems of insufficient sliding, flexible, inaccurate positioning, inconvenient operation, etc., and achieve the effect of consistent compaction, easy operation and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

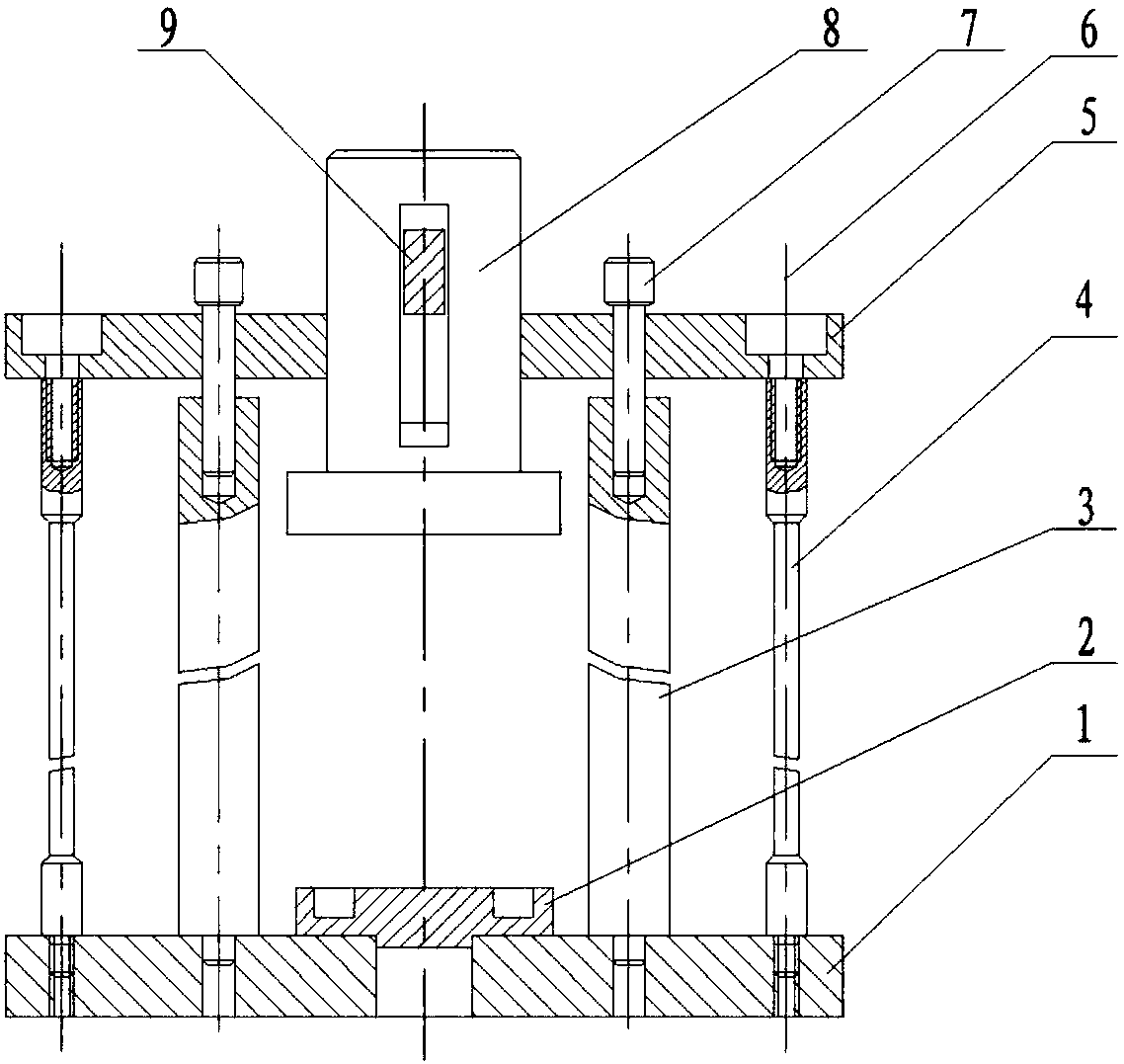

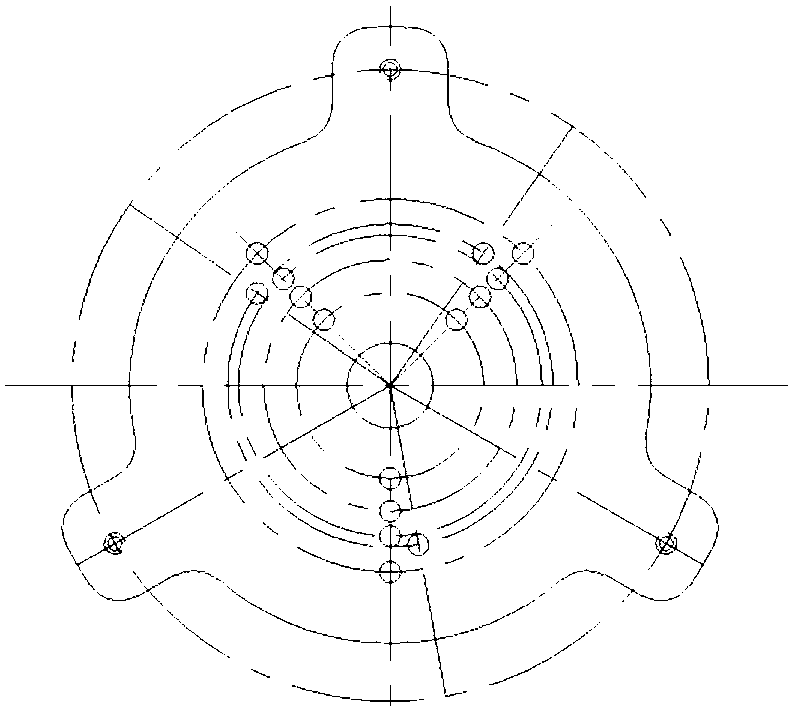

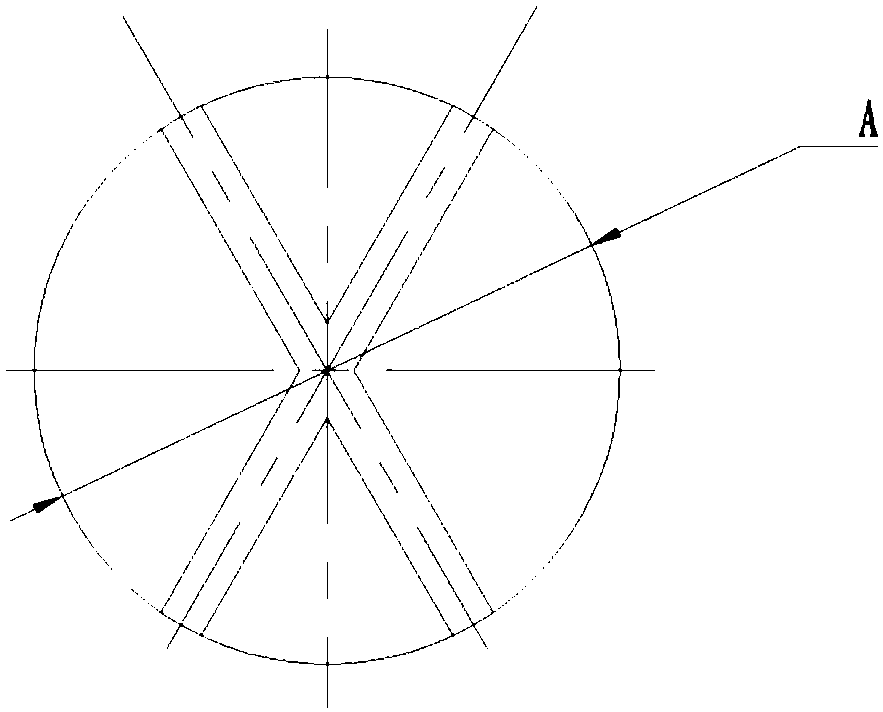

[0031] The present invention provides a general electric pile binding die, which is composed of a bottom plate, a spacer, a limit column, a column, an upper support plate, hexagonal socket screws, pins, a pressure head, and a wedge-shaped shim. The structure includes an upper support plate and a bottom plate with positioning holes in different positions, a rigid bracket connected together by hexagon socket screws and uprights; a limiting column fixed between the upper support plate and the bottom plate by pins; fixed on the bottom plate The pad on the top; the indenter that slides up and down in the center hole of the upper support plate; the wedge-shaped pad iron that slides left and right in the parallelogram strip hole in the center of the indenter. It is characterized i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com