Commutation failure prediction control method and device based on direct-current (DC) electric quantity

A commutation failure and predictive control technology, applied in power transmission and AC networks, etc., can solve problems such as long response time, ensure stable operation, avoid the problem of perfect pole commutation failure, and improve response speed and action accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

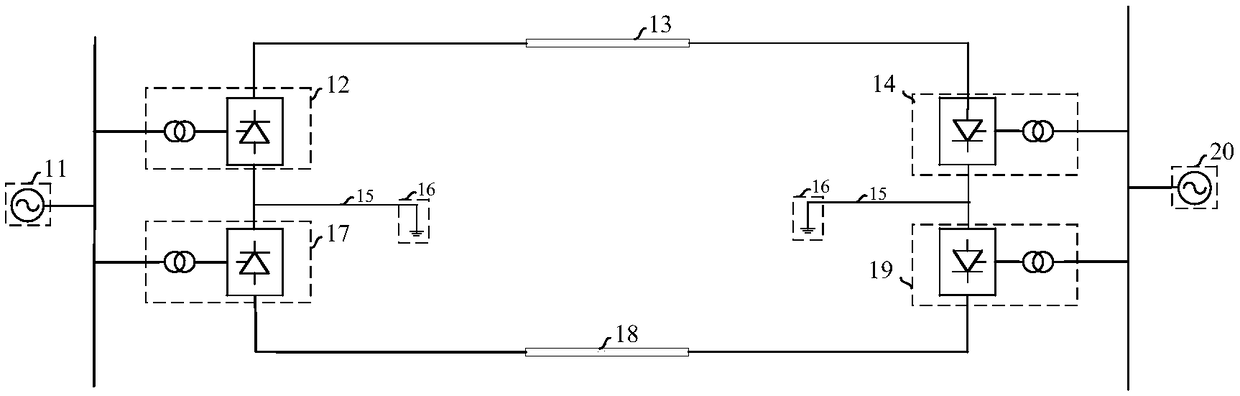

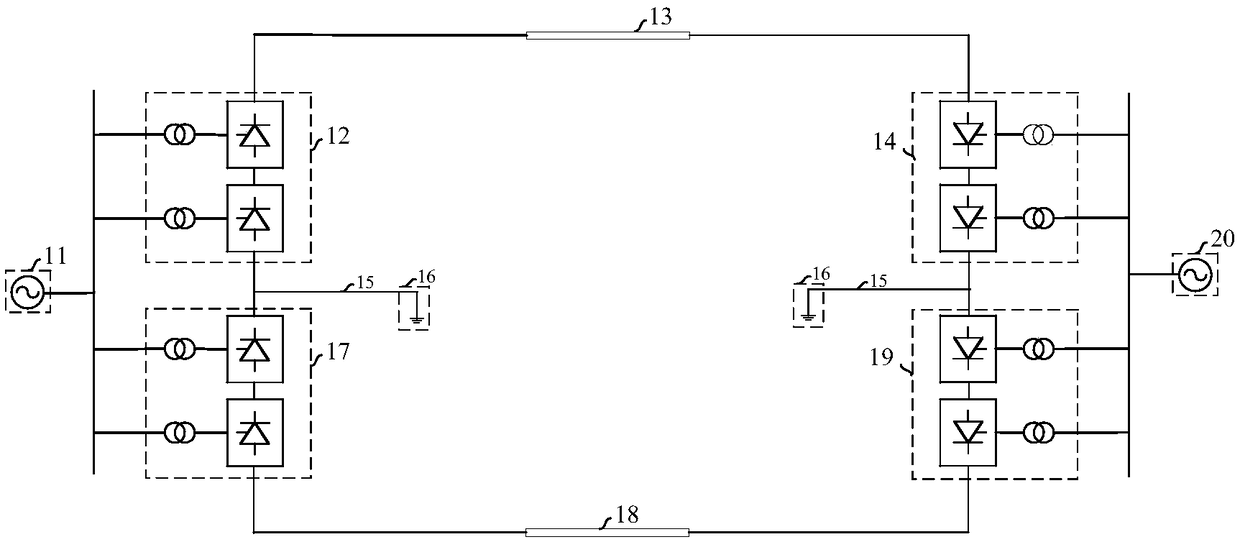

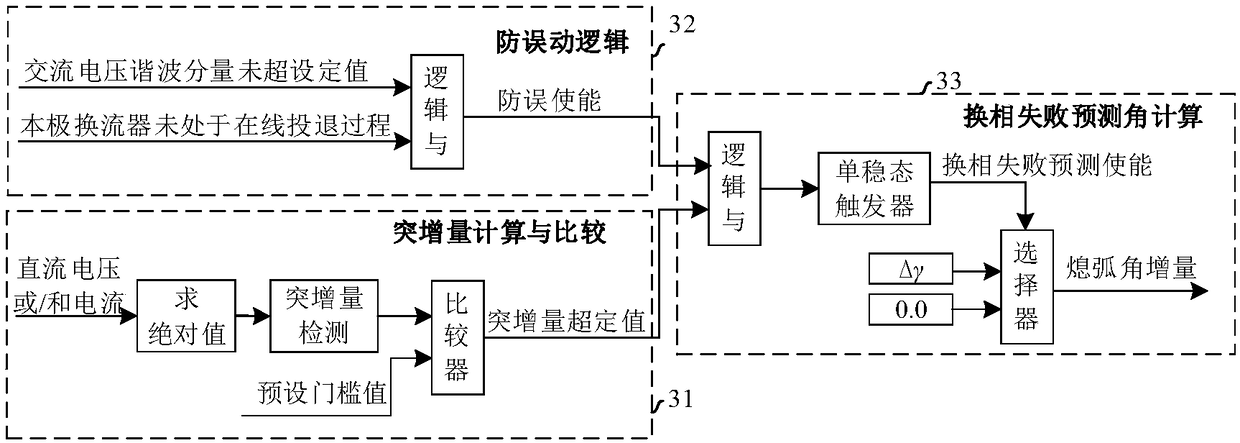

[0030] The commutation failure prediction control method and its device based on DC electrical quantity described in this patent are suitable for high-voltage and extra-high voltage DC systems. The principle structures of conventional HVDC and UHVDC systems are as follows: figure 1 and figure 2 shown. figure 1 and figure 2 The main difference between medium, high voltage and UHV DC systems is that the HVDC system contains only one converter per pole, while the UHV DC system contains two high-end and low-end converters per pole. Therefore, compared with the high-voltage direct current system, in the ultra-high voltage direct current system, the influence of the on-line switching process of the current-pole converter needs to be additionally considered in the commutation failure prediction control of the present invention. In actual engineering, the commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com