Method and machine for making pieces of a multilayer, cylindrical tubular rod used to make substantially cylindrical smokers' articles, and the pieces made by the method and machine

A cylindrical, smoker's technology used in the manufacture of cigarettes, tobacco, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

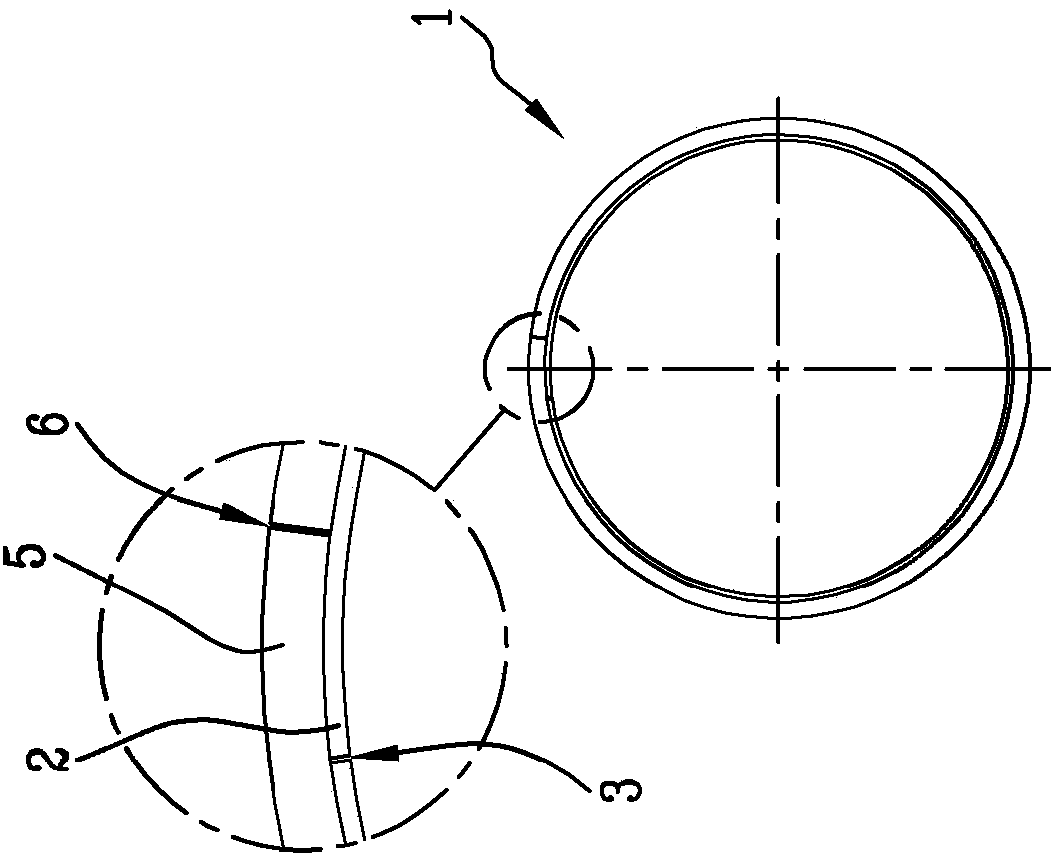

[0028] With reference to the drawings, reference numeral 1 denotes a multilayer cylindrical tubular rod from which a rod section suitable for manufacturing a substantially cylindrical smoker's article is obtained.

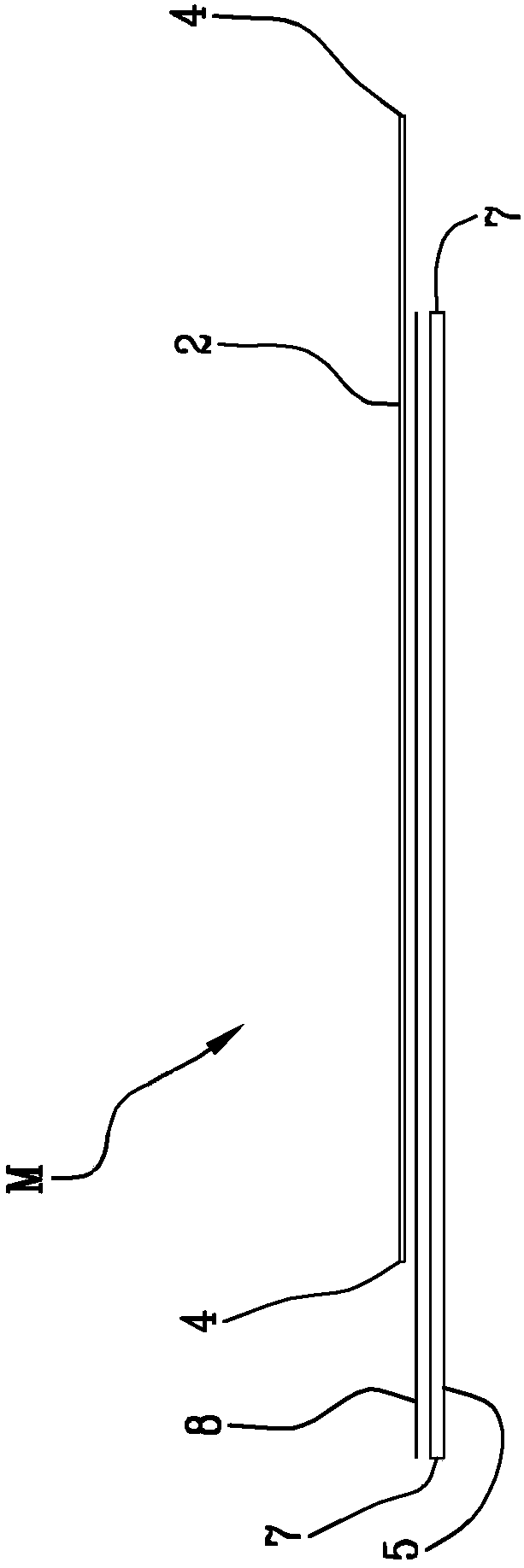

[0029] The rod 1 and the rod segments not shown comprise a first layer 2 of a first material. The first layer 2 is spliced longitudinally to form the first splicing portion 3 of the corresponding side edge 4 of the first layer 2.

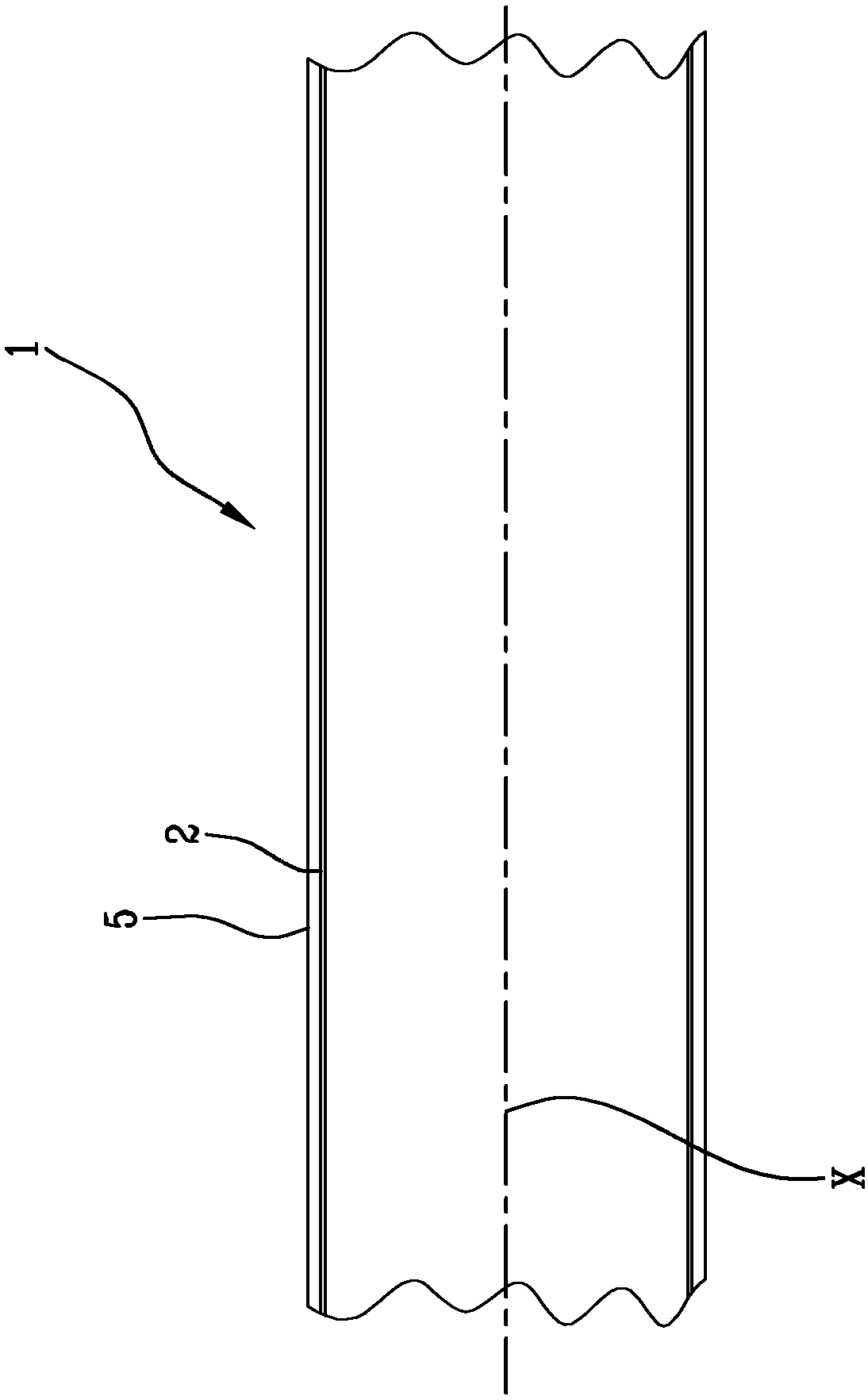

[0030] The rod 1 and therefore the not-shown rod segment comprises a second layer 5 of a second material. The second layer 5 is spliced longitudinally to form the second splicing portion 6 of the corresponding side edge 7 of the second layer 5.

[0031] The first layer 2 occupies a radially inner position relative to the second layer 5 in both the rod section and the rod 1

[0032] The second layer 5 is continuous along the main extension direction "X" of the rod 1, which is consistent with the feeding direction of the rod during the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com