Engine cooling fan housing shroud with unobstructed outlet

A shroud and fan technology, which is applied in the field of automotive axial flow fan components, can solve problems such as ineffective operation, and achieve the effects of reducing material costs, low fan noise, and high fan efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

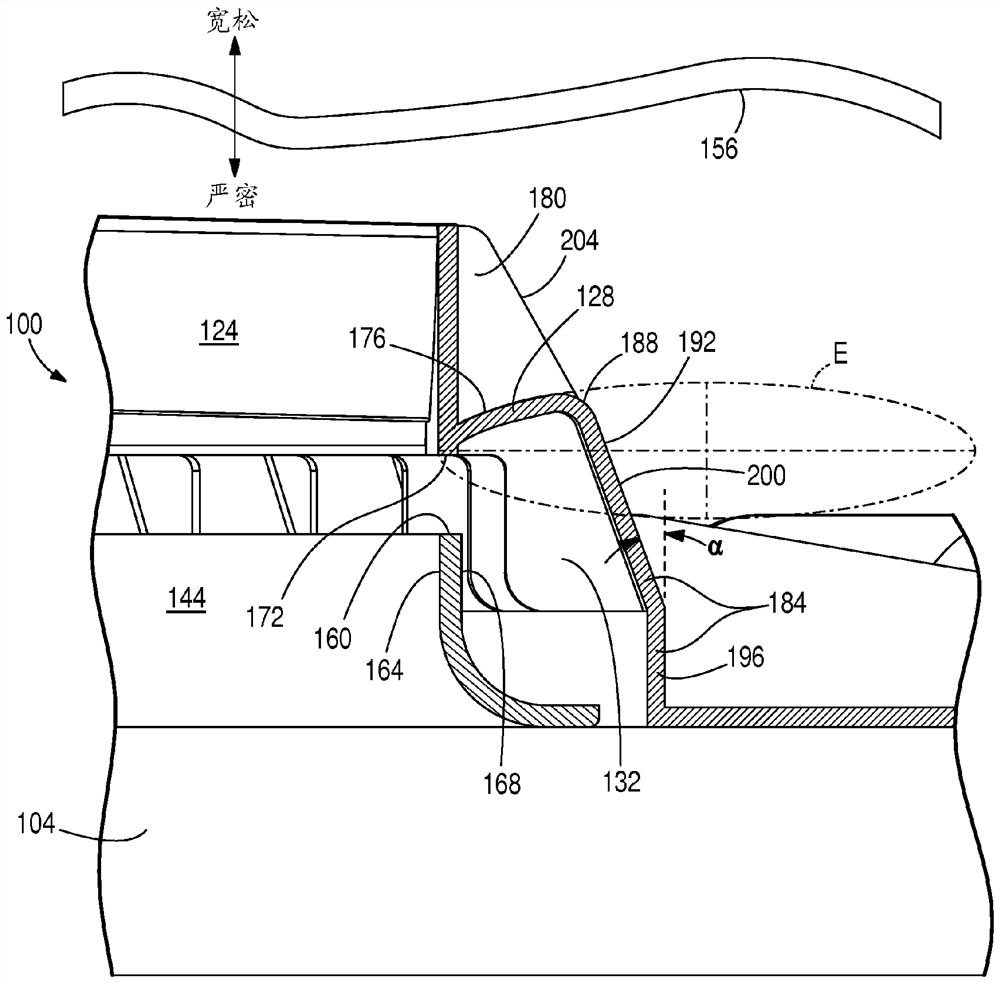

[0024] Figure 4 A axial flow fan assembly 100 is shown comprising a shroud 104, a motor 108 coupled to the shroud 104, and an axial fan 112 coupled to the motor 108 and driven by the motor 108. Special, such as Figure 4 As shown, the motor 108 includes an output shaft (not shown) to drive an axial flow fan 112 around the central axis 116 of the axial flow fan 112. In the illustrated embodiment, the shroud 104 is a molded part of a single part.

[0025]The axial flow fan assembly 100 is configured to be coupled to the heat exchanger with "suction pass" such that the axial flow fan 112 is sucks the airflow through the heat exchanger. Alternatively, the axial flow fan assembly 100 can be coupled to the heat exchanger with "push through" such that the axial flow fan 112 discharges the airflow through the heat exchanger. The axial flow fan assembly 100 can be coupled to the heat exchanger using any connector in multiple different connector.

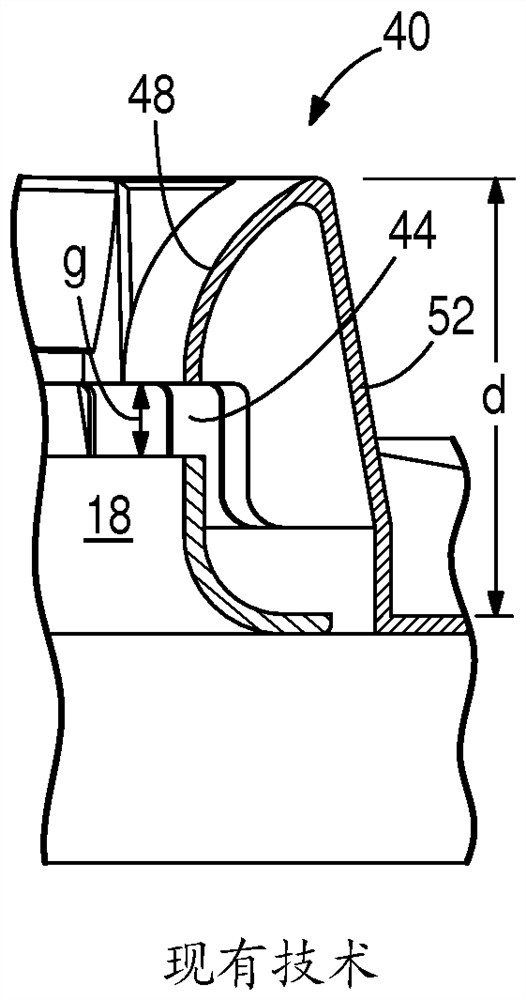

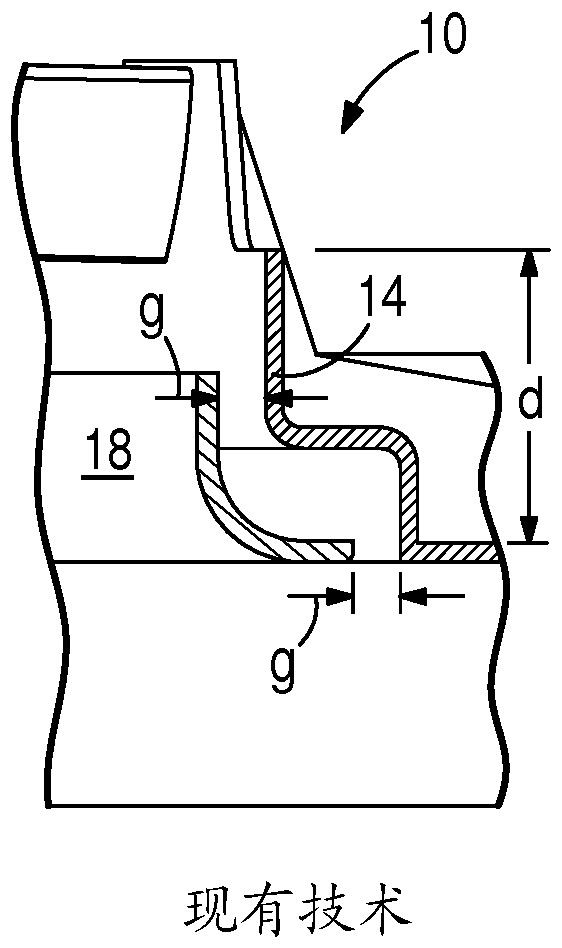

[0026] in Figure 4 In the illustrated s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com