Coil for overlength handling of an electric cable

A cable, extra-long technology, applied in the field of coils, which can solve the problems of extended maintenance operation duration, operator fatigue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

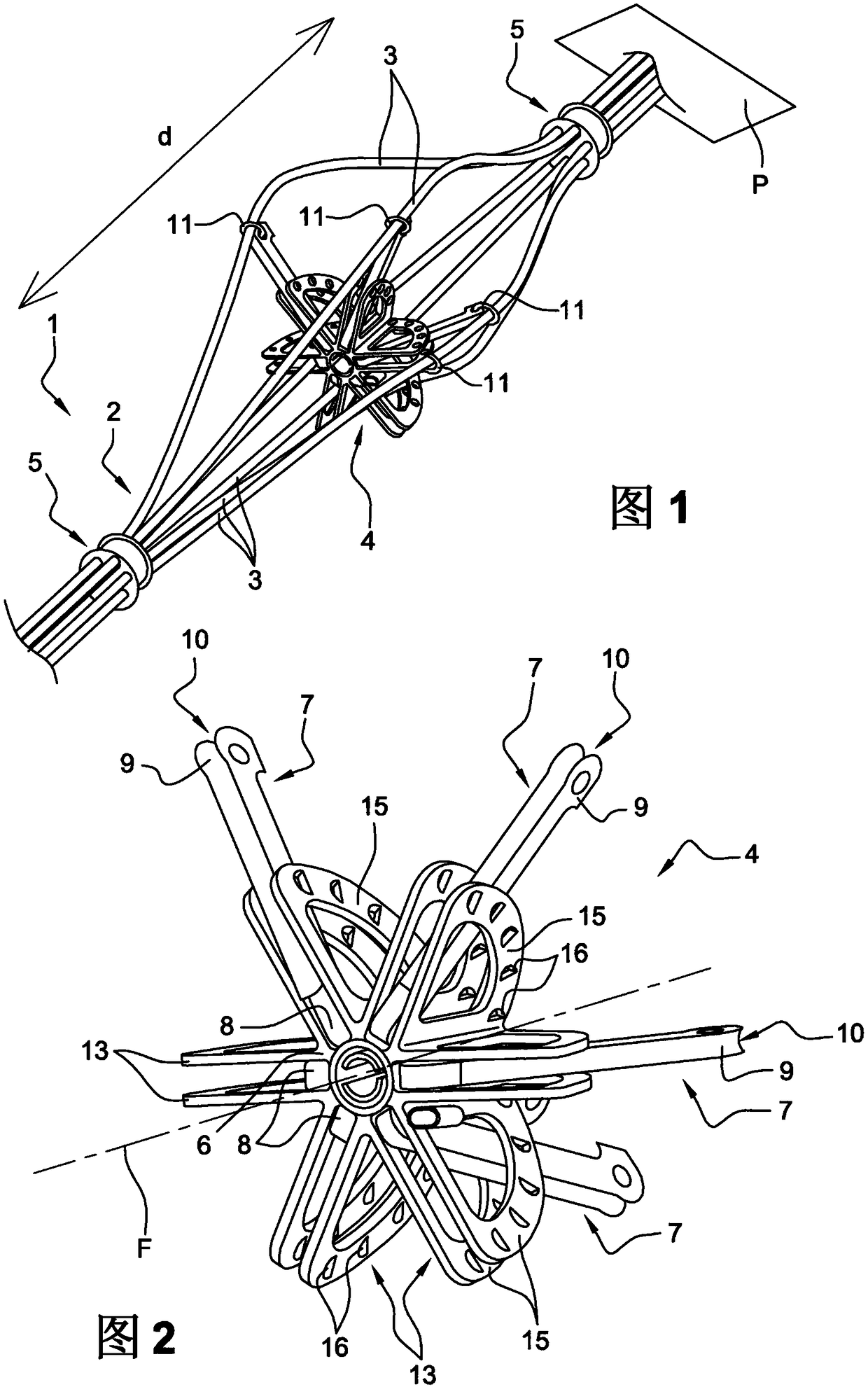

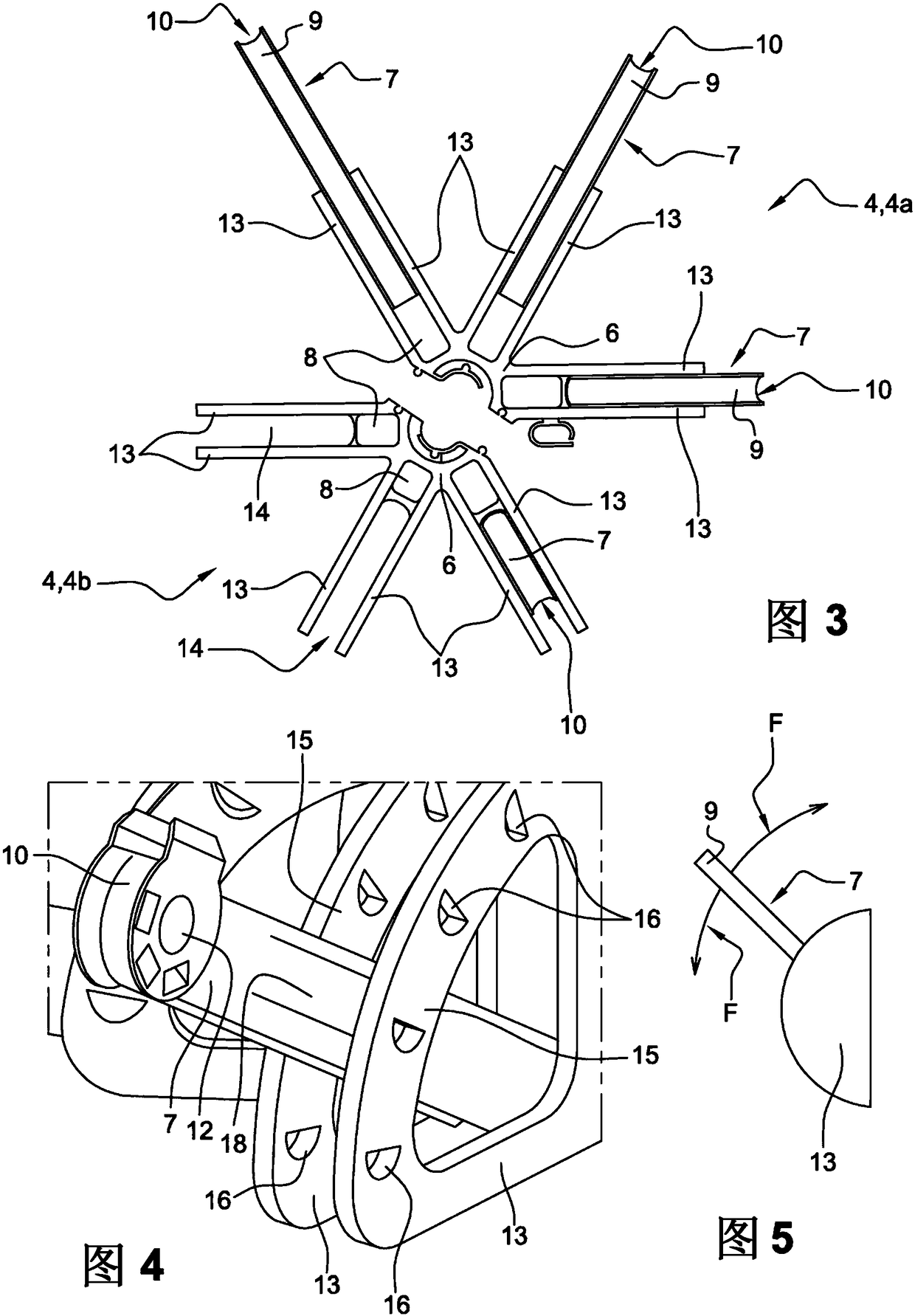

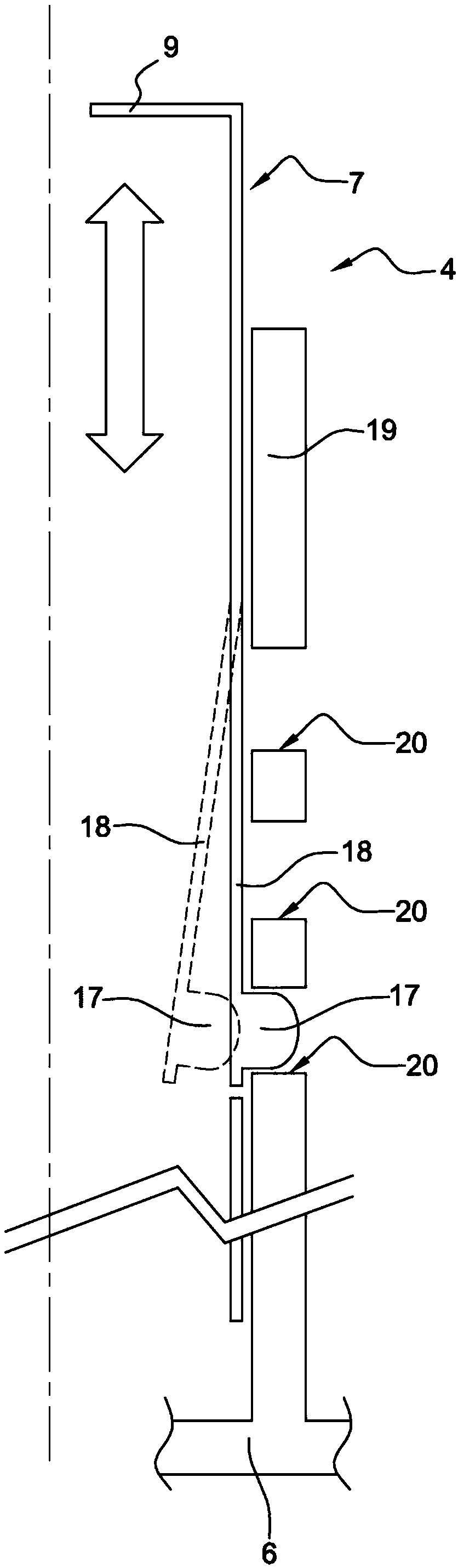

[0039] Figure 1 shows an assembly 1 comprising:

[0040] - a wire harness 2 wound as a coil, said wire harness comprising a plurality of electric wires 3; and

[0041] - An extra long control coil 4 to which said cable 3 is fixed.

[0042] The harness 2 , here an electrical harness 2 , comprising several cables 3 , here six, held together by cable grommets 5 , has roughly the shape of a sheath. The wire bundles 2 wound as a coil arrangement, here the cables 3 forming the wire bundle 2 , are substantially parallel to one another and are not twisted together so that no zero phase-sequence impedance arises.

[0043] Before installing the harness 2 on the part of the aircraft, the harness 2 is assembled by an operator who feeds several cables 3 independently of each other and assembles them using cable grommets 5 .

[0044] The independent feeding of the cables 3 makes the bundle 2 irregular, ie each end of a cable 3 is not entirely in the same plane P as the ends of the other c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com