System and method for fusing outputs of sensors having different resolutions

A sensor and resolution technology, applied in the field of sensing systems, which can solve problems such as low resolution and inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

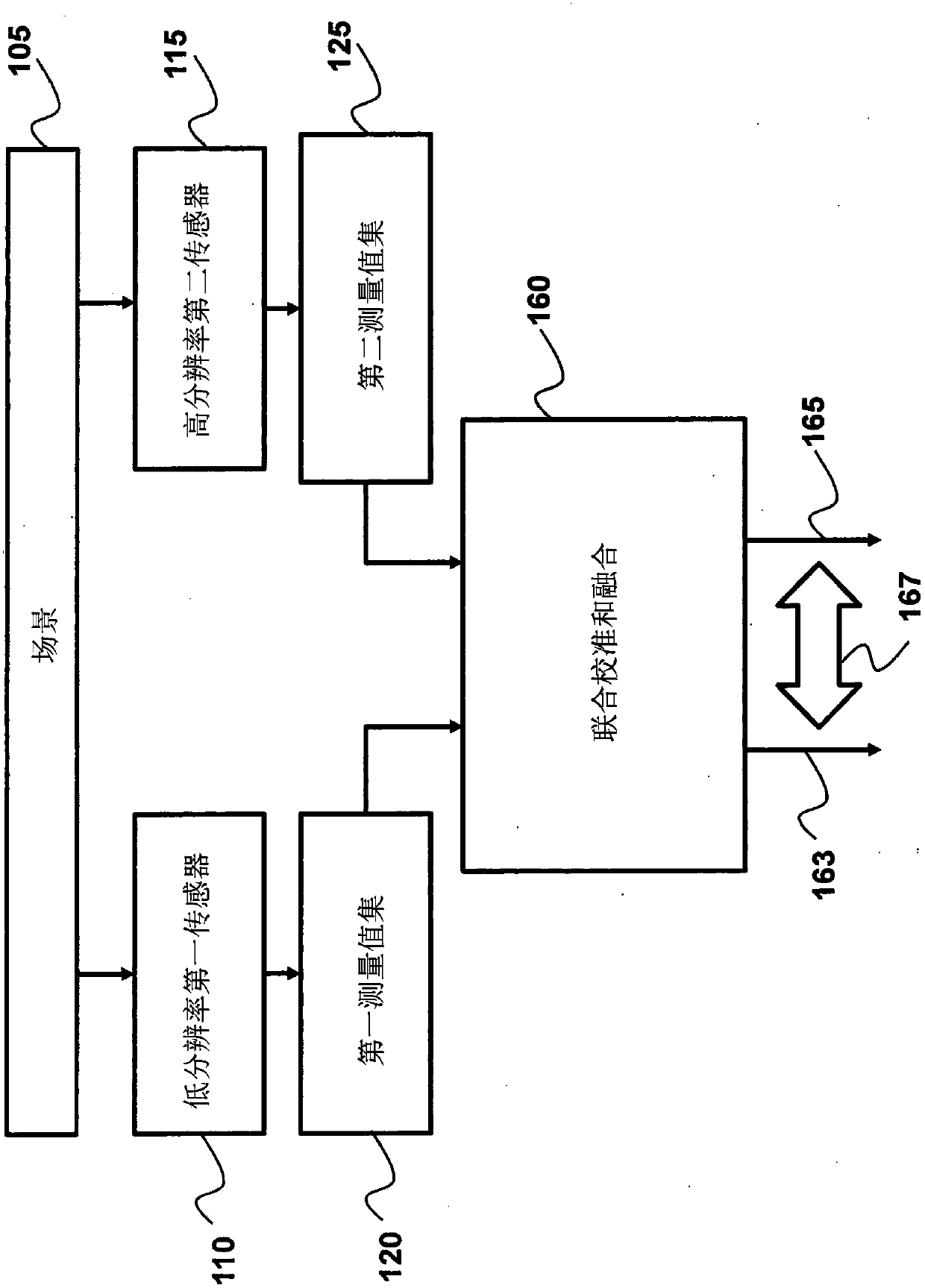

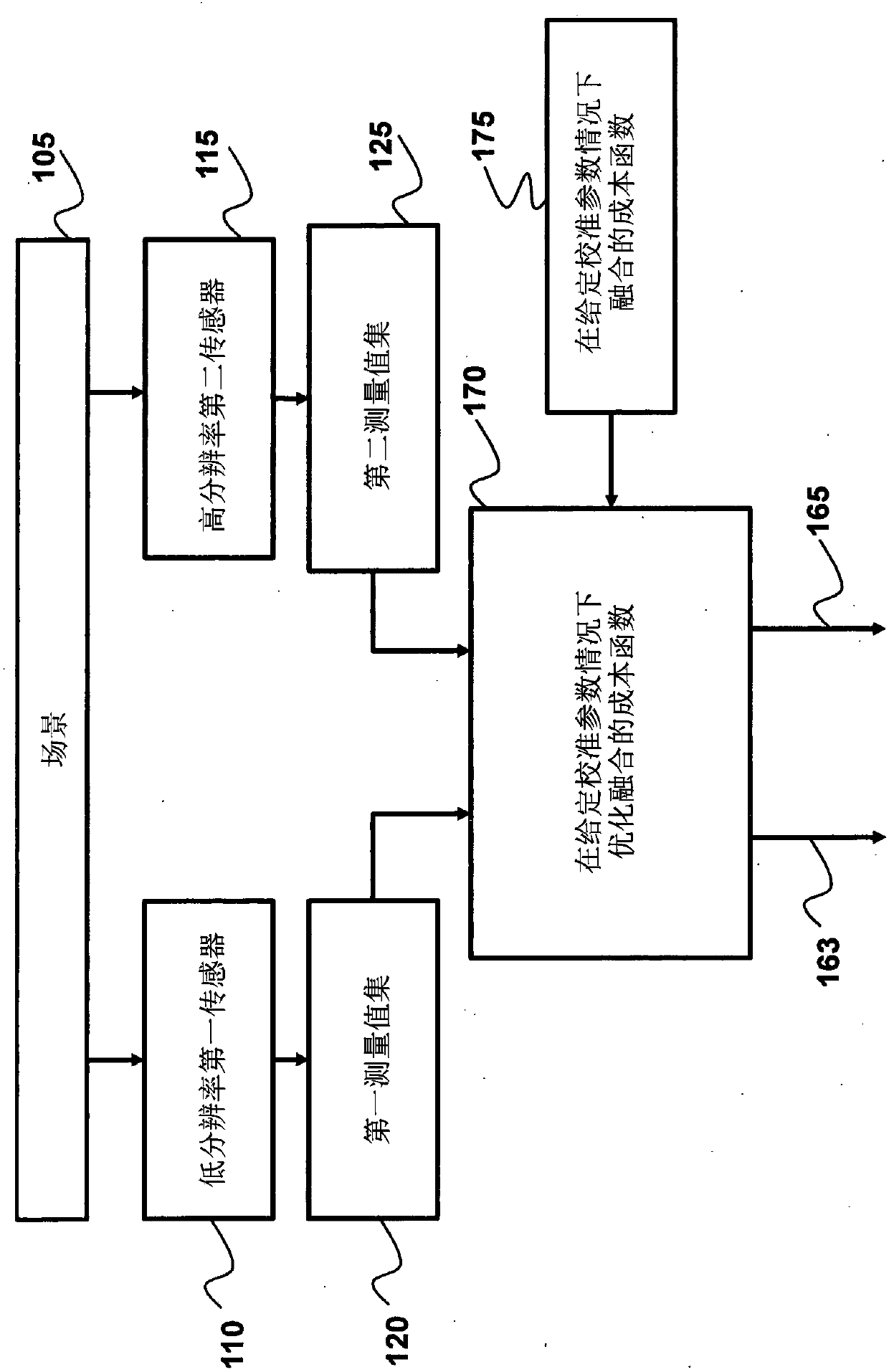

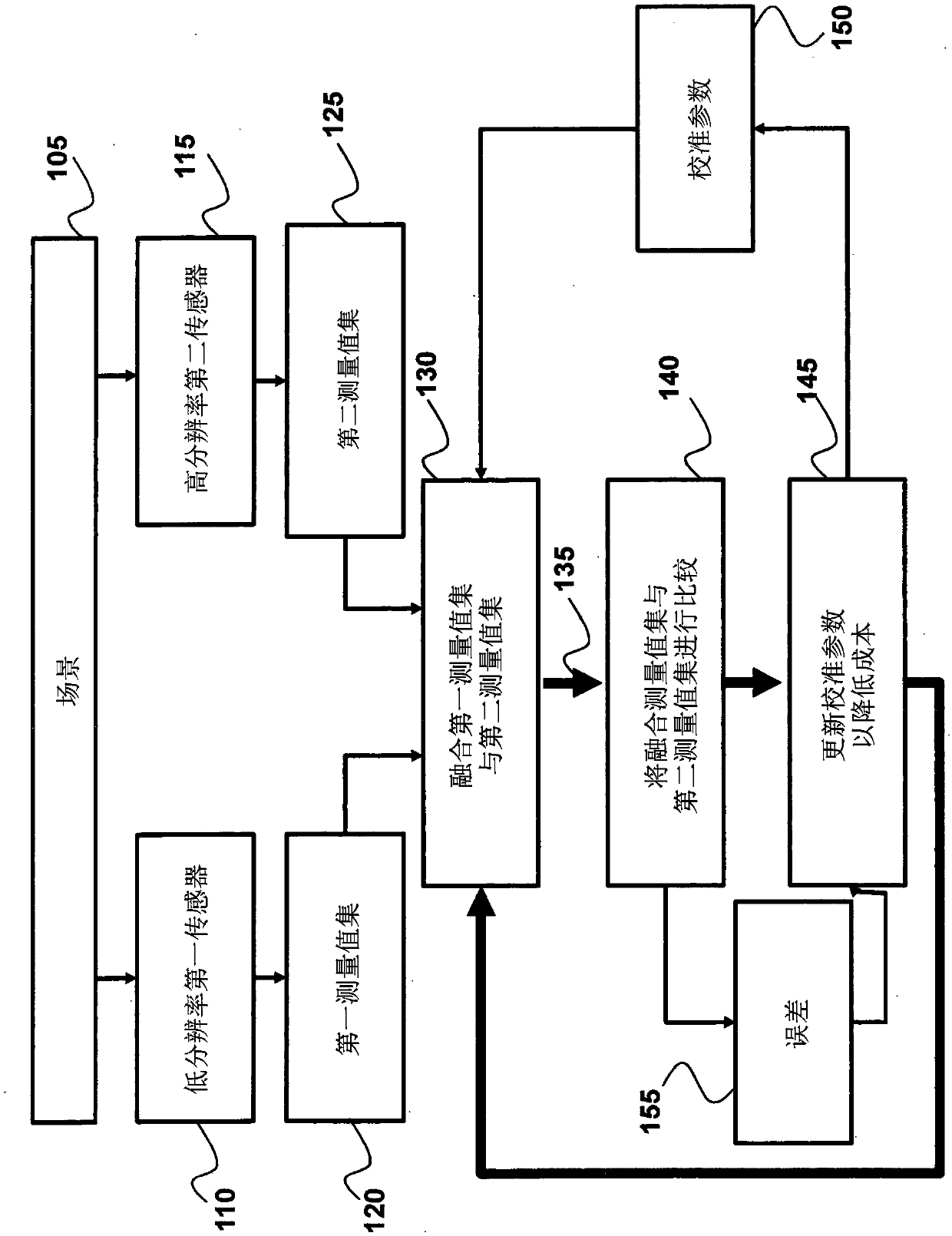

[0019] Figure 1A A block diagram of a method for jointly performing calibrating sensors and fusing sensor measurements according to some embodiments of the invention is shown. The method acquires 120 a first set of measurements of the scene 105 from the first sensor 110 and also acquires 125 a second set of measurements of the scene 105 from the second sensor 115 .

[0020] The steps of the method are performed with a processor, such as a processor internal or external to one of the sensors. Measurements may be taken directly from the sensors, or indirectly, eg from memory storage and / or via wired or wireless communication channels. In some embodiments, the resolution of the first sensor is lower than the resolution of the second sensor. Exceptionally, in some embodiments, the modality of the first sensor is different than the modality of the second sensor.

[0021] Some implementations utilize sensor numbers of different types and / or modalities to identify information abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com