Anti-repeated heating device for water dispenser

A technology of repeated heating and water dispenser, applied in heating devices, beverage preparation devices, applications, etc., can solve problems such as overheating of food, low flame heating efficiency, heat energy loss, etc., to maintain fresh taste and characteristics, improve heating efficiency, Heat loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

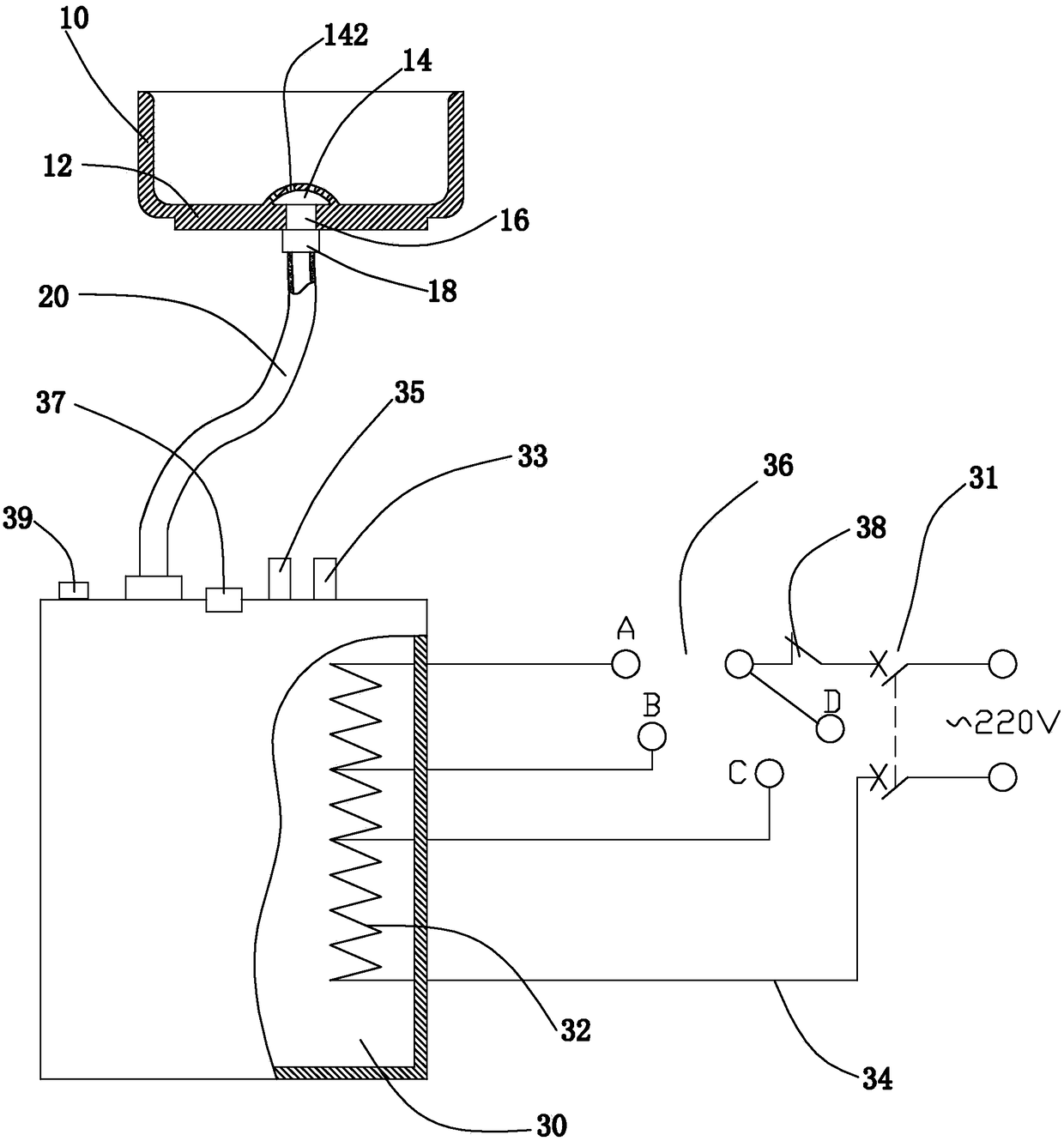

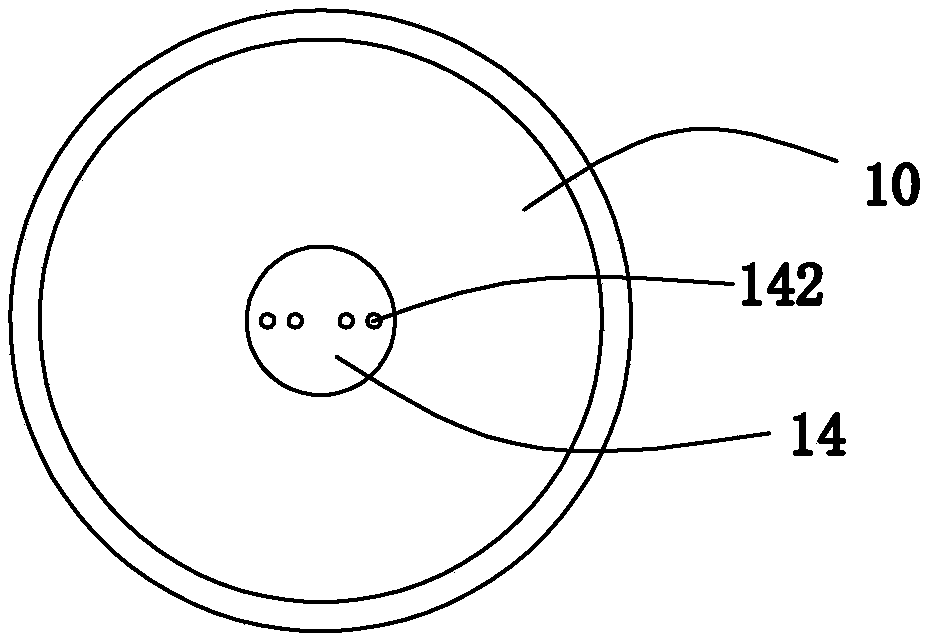

[0010] The invention provides a new device for cooking food using steam. Compared with the traditional technology, the cooking device has two outstanding features: first, the invention adopts a water dispenser body made of non-metallic materials to prevent repeated heating. Replacing the traditional metal container, not only the heat loss is reduced, the heat transfer efficiency is improved, but also the heating is uniform; secondly, the present invention directly passes the steam into the body of the anti-reheating device for the non-metal water dispenser, through the heat of the steam and the water in the container. Exchange action to quickly bring water to a boil and quickly scald or cook food. In this way, not only the heating efficiency is improved, the heating time is shortened, but also the food can be cooked just right, and its original flavor and characteristics can be maintained without overheating or overheating. The following will be described through several speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com