Method for preventing condensation blocking of liquid level meter at bottom of heavy alkyl benzene fractionation tower

A technology for heavy alkyl benzene and alkyl benzene towers, which is applied in the field of anti-condensation blockage of liquid level gauges at the bottom of fractionation towers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

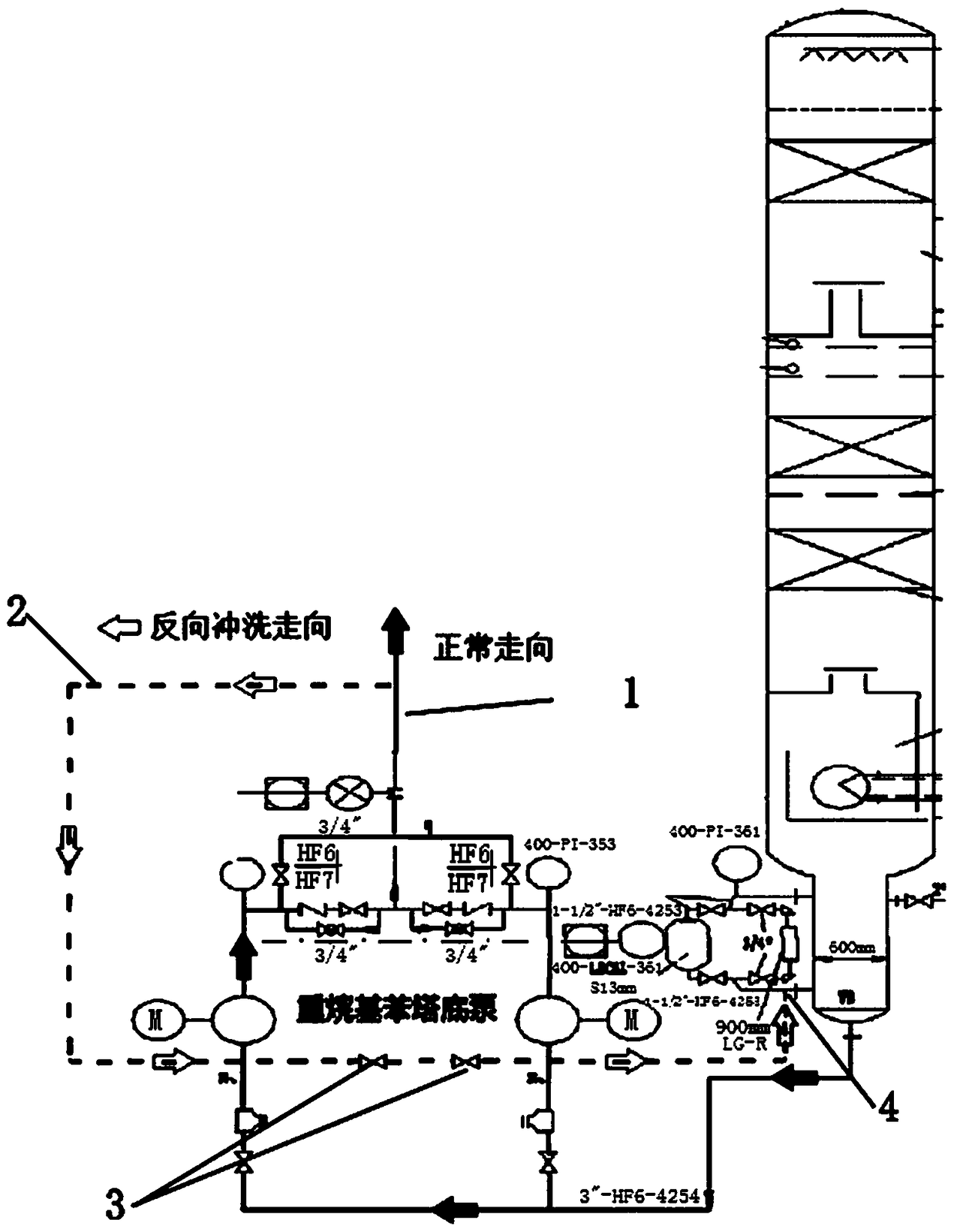

[0011] Such as figure 1 As shown, the method for anti-condensation plugging of the liquid level gauge at the bottom of the heavy alkylbenzene fractionation tower of the present invention, the specific operation is: draw a pipeline 2 with a pipe diameter of 1 inch from the outlet 1 of the bottom pump of the heavy alkylbenzene fractionator, and connect it to The heavy alkylbenzene tower bottom liquid level gauge is at the outlet of the pressure pipeline 4, and two hand valves 3 are added on the pipeline 2, one is fully opened and the other is kept open to adjust the backwash flow at the pump outlet. The high-temperature tower bottom material returns to the bottom liquid level pipeline through pipeline 2 with a small flow rate for backwashing.

[0012] According to the anti-coagulation plugging method for the liquid level gauge at the bottom of the heavy alkylbenzene fractionation tower of the present invention, the outlet temperature of the heavy alkylbenzene tower bottom pump i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com