Equipment and control method for automatically feeding, broaching grooves and drawing lines

A technology of automatic feeding and slotting, applied in workshop equipment, slotting machines, manufacturing tools, etc., can solve the problems of inability to adjust the depth of the slot, low precision accuracy, low straightness, etc., and achieve the effect of reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

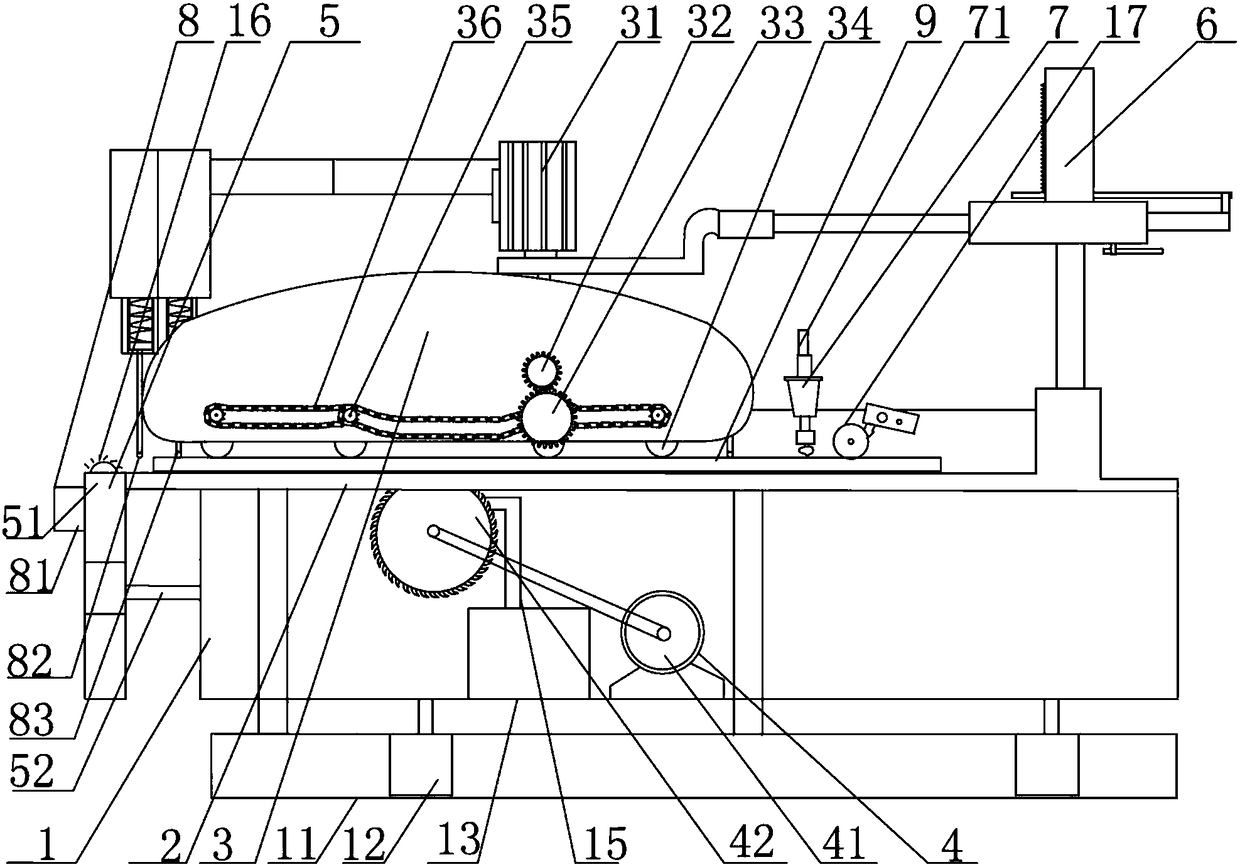

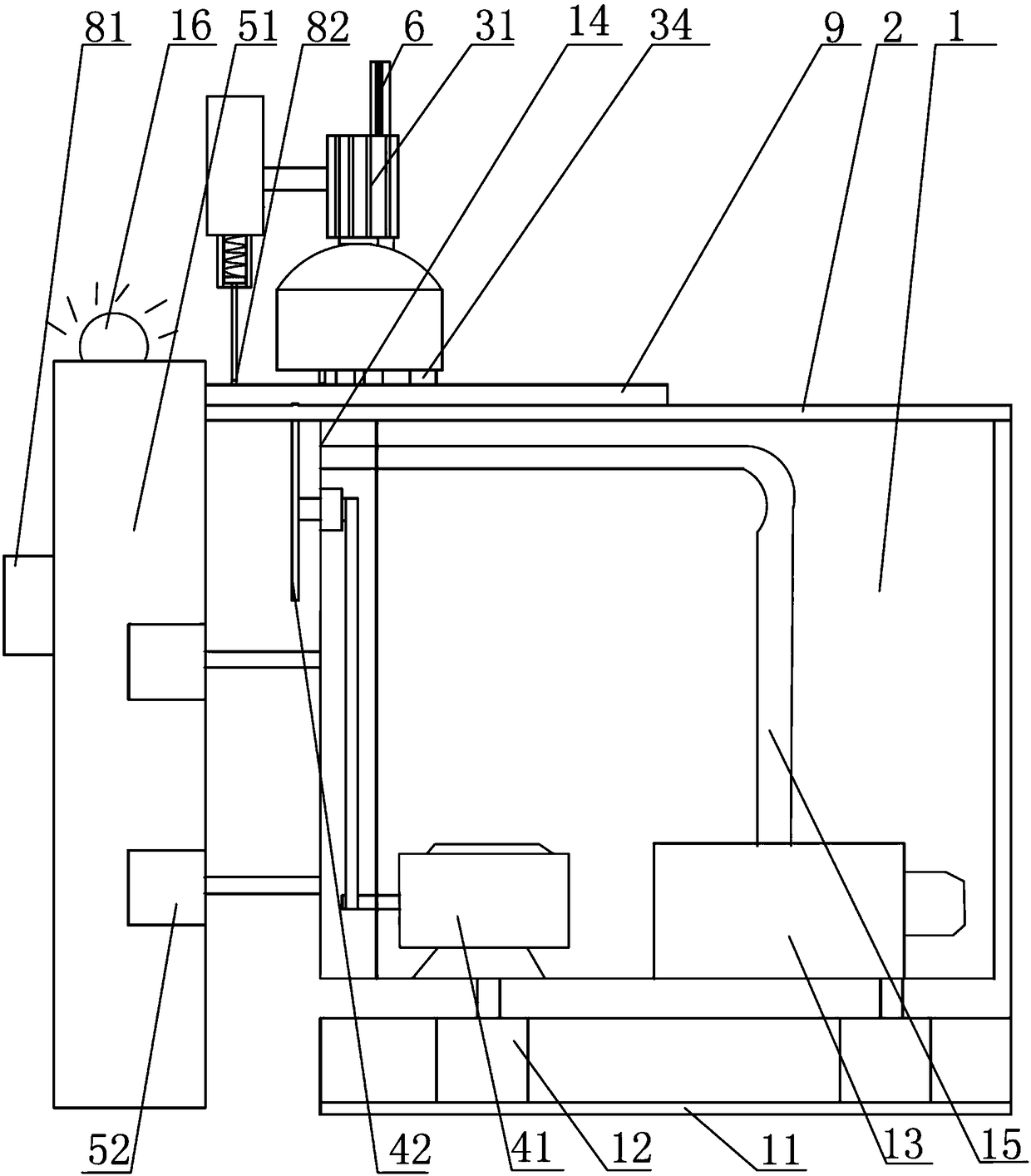

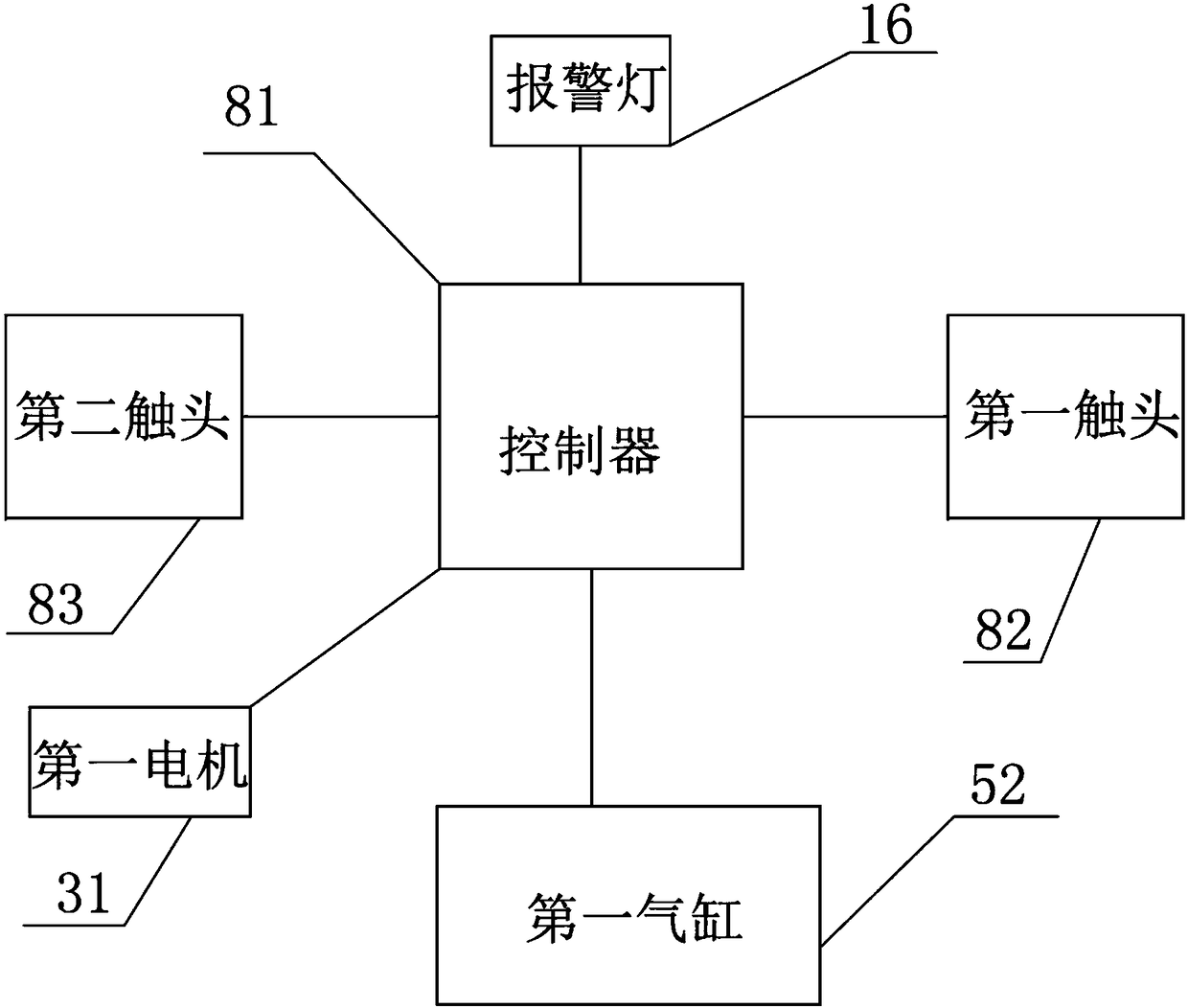

[0039] refer to figure 1 as well as figure 2 , a device for automatically feeding and pulling grooves and drawing lines, including a frame 1, a workbench 2 on the top of the frame 1, a feeding device 3, a chainsaw device 4, a baffle device 5, and driving the feeding device 3 up and down, front and rear directions The first adjustment device 6 of the movement, the first adjustment device 6 can adjust the feeding device 3 to make it match the planks of different thicknesses; in this equipment, it also includes a paintbrush device 7 and a control device 8, and the baffle device 5 includes a baffle Plate 51 and the first cylinder 52 fixed on the horizontal direction on the baffle plate 51, the output shaft of the first cylinder 52 is connected with the vertical surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com