Suction type preparation device and method for fabric with gradient change of elasticity in thickness direction and application

A gradient change, fabric thickness technology, applied in the direction of fabric surface trimming, textile and papermaking, spray/jet textile material treatment, etc., can solve the problem of few reports of preparation devices, and achieve the effect of simple operation and dry wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

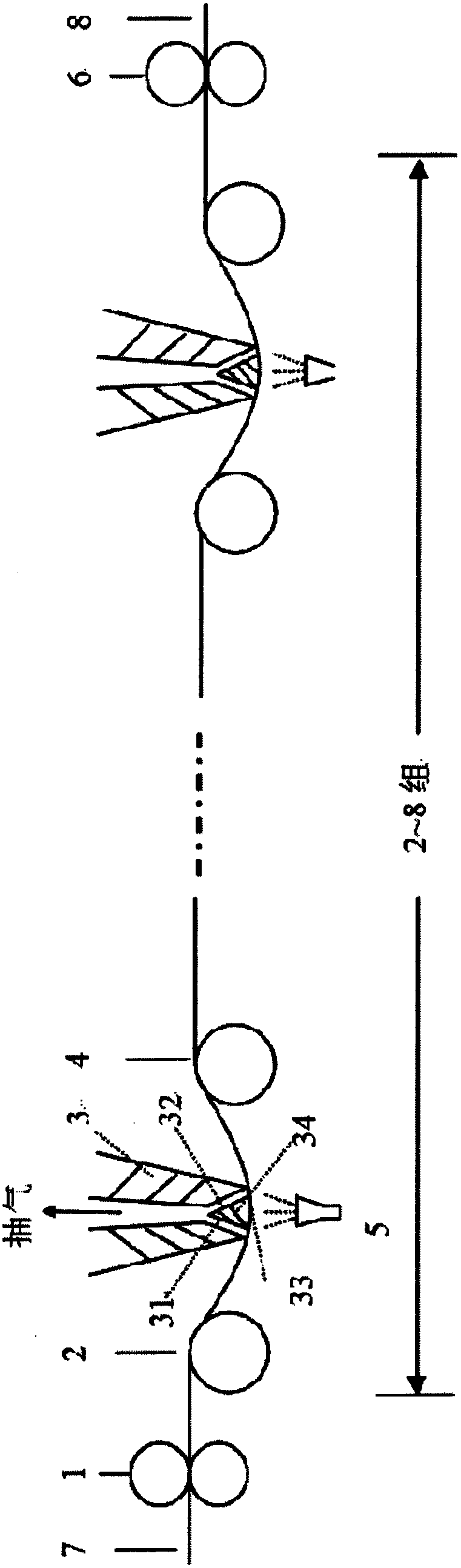

[0042] Pure cotton plain weave fabric: 1 upper and 1 lower plain weave fabric can be densified on the front side and loosened on the reverse side through 3 sets of suction and heat pressing mechanism, feeding smooth fabric guide roller and outputting the output of the fabric with gradient structure in the thickness direction The composition of the roller; the suction rate of the suction hole is 10ml / s. The heating bar temperature was adjusted to 100°C. Spray the wet mist, and spray water vapor to the reverse side of the fabric every 2S.

[0043] Experiment: When the fabric absorbs 50% of its own weight, that is, when the moisture regain rate is 50%, the inner side is still dry and comfortable to wear; the outer side is colored in 2.1 sec, which shows that its one-way moisture transfer is fast. Therefore, it is proved It is effective and practical to adjust the tightness gradient of the fabric with a simple device, and the obtained fabric has a high-efficiency one-way perspira...

Embodiment 2

[0045] Pure cotton twill fabric: 2 upper and 1 lower plain weave fabrics can be densified on the front side and loosened on the reverse side by 3 sets of plain weave fabrics, the suction and heat press mechanism for feeding flattened fabrics and the output of fabrics with a gradient structure in the thickness direction The composition of the roller; the suction rate of the suction hole is 10ml / s. The heating bar temperature was adjusted to 100°C. Spray the wet mist, and spray water vapor to the reverse side of the fabric every 2S.

[0046] Experiment: When the fabric absorbs 50% of its own weight, that is, when the moisture regain rate is 50%, the inner side is still dry and comfortable to wear; the outer side is colored in 1.9sec, which shows that its one-way moisture transfer is fast. Therefore, it is proved It is effective and practical to adjust the tightness gradient of the fabric with a simple device, and the obtained fabric has a high-efficiency one-way perspiration fu...

Embodiment 3

[0048] Polyester-cotton (65 / 35) plain weave fabric: 1 up and 1 down plain weave fabric can be densified on the front side and loosened on the back side through 3 sets of suction and heat pressing mechanism, feeding smooth fabric guide roller and output thickness direction The output roll of the gradient structure fabric is composed; the suction rate of the suction hole is 10ml / s. The heating bar temperature was adjusted to 110°C. Spray the wet mist, and spray water vapor to the reverse side of the fabric every 2S.

[0049] Experiment: When the fabric absorbs 50% of its own weight, that is, when the moisture regain rate is 50%, the inner side is still dry and comfortable to wear; the outer side is colored in 1.8 sec, which shows that its one-way moisture transfer is fast. Therefore, it is proved It is effective and practical to adjust the tightness gradient of the fabric with a simple device, and the obtained fabric has a high-efficiency one-way perspiration function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com