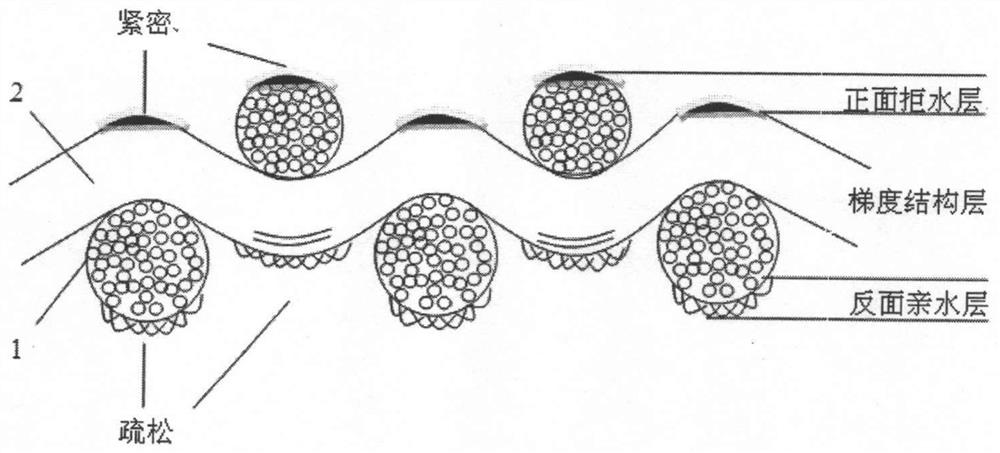

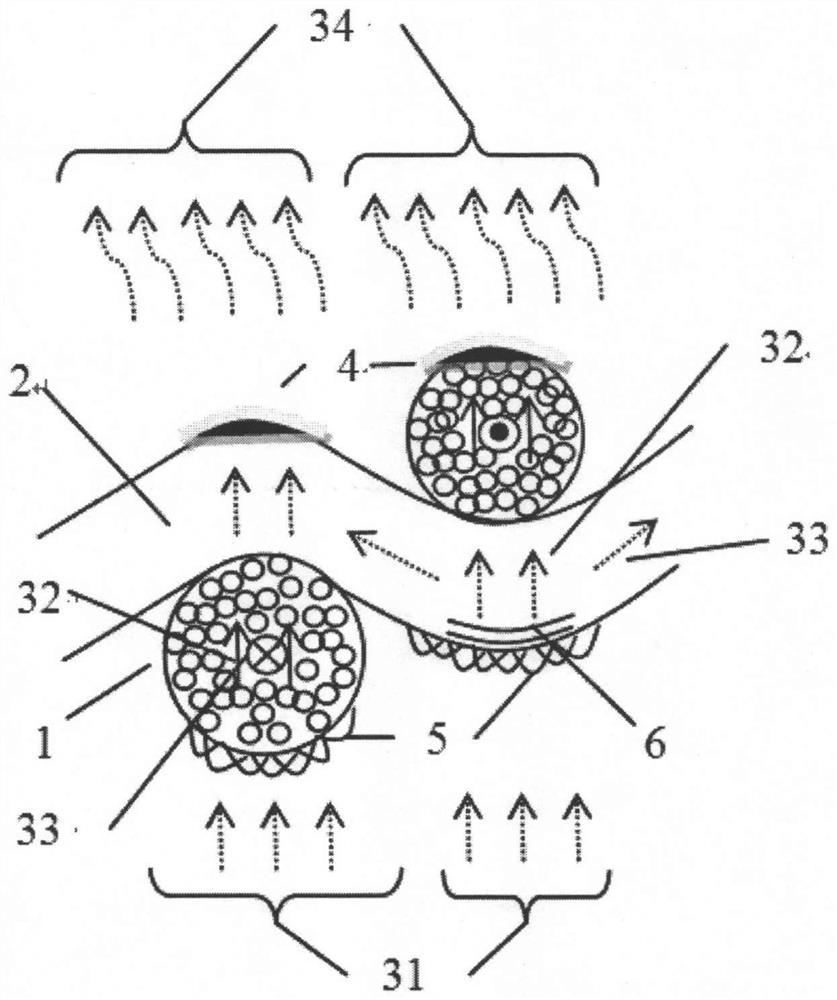

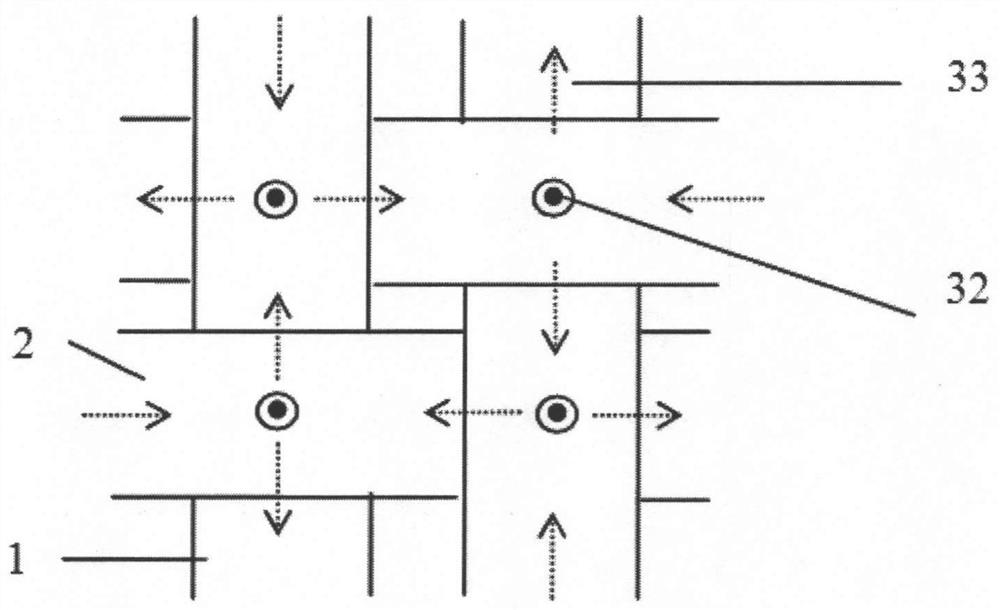

A kind of water-repellent and perspiration-wicking double-sided functional fabric with gradient structure and its application

A technology of functional fabrics and gradient structures, applied in fabrics, textiles, textiles and papermaking, etc., can solve problems such as inability to wick away sweat, retain weight gain, and limit sweat absorption, and achieve the effect of practical methods and simple operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Polyester fabric: The contact angle of the polyester fiber after plasma treatment is 60°. After the front surface of the fabric is pressed, the contact angle of the surface layer is 90°. Under normal conditions, the moisture regain of polyester fiber is 0.4%, and after plasma treatment, it can reach 1.6-1.8%. Therefore, the moisture regain of the polyester fabric with double-sided water-repellent and sweat-wicking functions made of this fiber is 2.0- 2.1%. When the water absorption of the polyester fabric reaches 25% of its own weight, which is equivalent to the moisture regain of the fabric is 27.1%, after placing it for 30 minutes, the moisture regain of the polyester fabric returns to 2.3%; when the water absorption reaches 50% of the polyester fabric itself, place it for 45 minutes, the fabric The moisture regain dropped from 52.0% to 2.8%, all in a dry state. On the other side, after 1 minute of water supply, there is no water trace and normal contact pressure (3g...

Embodiment 2

[0048] Polypropylene fabric: The contact angle of the polyester fiber after plasma treatment is 73°. After the front surface of the fabric is pressed, the contact angle of the surface layer is 161°. Under normal conditions, the moisture regain of polypropylene fiber is 1.0%, and it can reach 1.7-1.8% after plasma treatment. Therefore, the moisture regain of the polypropylene fabric with double-sided water-repellent and sweat-wicking functions made of this fiber is 2.5-1.5%. 2.6%. When the water absorption of the polyester fabric reaches 25% of its own weight, which is equivalent to the moisture regain of the fabric is 27.6%. After placing it for 30 minutes, the moisture regain of the polyester fabric returns to 2.3%. When the water absorption reaches 50% of the polyester fabric itself, place it for 45 minutes. The moisture regain dropped from 50% to 2.8%, all in a dry state. On the other side, after 1 minute of water supply, there is no water trace and normal contact pressure...

Embodiment 3

[0050] Polylactic acid fiber fabric: The contact angle of the polylactic acid fiber after plasma treatment is 55°. After the front surface of the fabric is pressed, the contact angle of the surface layer is 158°. 32°. Under normal conditions, the moisture regain of polylactic acid fiber is 0.5%, and it can reach 2.8-2.9% after plasma treatment. 3.0 to 3.1%. When the water absorption of the polylactic acid fiber fabric reaches 25% of its own weight, it is equivalent to a moisture regain of the fabric of 28.1%. After placing it for 30 minutes, the moisture regain of the polylactic acid fiber fabric returns to 2.3%; when the water absorption reaches 50% of the polylactic acid fiber fabric itself , placed for 45min, the moisture regain of the fabric decreased from 50% to 3.0%, all in a dry state. On the other side, after the water supply is completed for 1 minute, there is no water trace and normal contact pressure (3g / cm2) 2 ) was measured to be 1.4% wet. In the measurement o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com