Preparation method and application of segmented tension dense and loose gradient structure fabric

A gradient structure, tension type technology, applied in the direction of fabric elongation, fabric surface trimming, heating/cooling fabric, etc., to achieve the effect of dry wearing, practical method and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

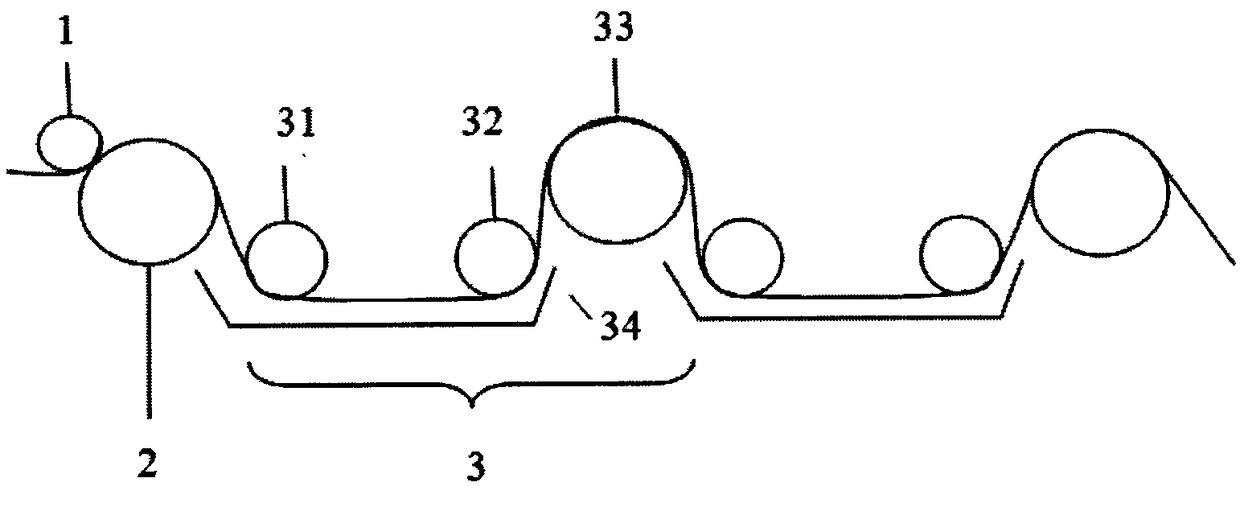

[0033]Pure cotton plain weave: 1 upper and 1 lower pure cotton plain weave fabrics are subjected to densification and flattening processing on the front of the fabric through a tension-type segmental processing device; The enveloping angle of the tension of the fabric and the differential movement of the front and rear rollers are used to process the reverse side of the fabric with micro-looping and loosening; and then carry out the processing of the densification and flattening of the front of the fabric by the upward compression of the thermal tension auxiliary roller, and the effect is stable. Finally, the gradient structure fabric with tight front and loose back is led out by the rear guide roller. The temperature of the hot tension main roller and the hot tension auxiliary roller is adjusted to 120 °, and at the same time, the fabric passes through the liquid tank (surfactant is added in the liquid tank) to realize the hydrophilic finishing of the reverse side of the fabri...

Embodiment 2

[0036] Pure cotton twill fabric: 2 upper and 1 lower twill fabrics are subjected to densification and flattening processing on the front of the fabric through a tension type segmental processing device; The enveloping angle of the tension and the differential movement of the front and rear rollers are used to process the reverse side of the fabric with micro-pile and loosening; then carry out the processing of densification and flattening of the front of the fabric by pressing the hot tension auxiliary roller upwards and the effect is stable, and finally , the fabric with a gradient structure that is tight on the front and loose on the back is led out by the rear guide roller. The temperature of the hot tension main roll and the hot tension auxiliary roll is adjusted to 140 °, and at the same time, the fabric passes through the liquid tank (surfactant is added in the liquid tank) to realize the hydrophilic finishing of the reverse side of the fabric.

[0037] Experiment: When ...

Embodiment 3

[0039] Polyester-cotton (65 / 35) plain weave fabric: 1 upper and 1 lower polyester-cotton fabrics are subjected to densification and flattening processing on the front of the fabric through a tension type segmental processing device; The front and rear rollers change the tension enveloping angle of the fabric and the differential movement of the front and rear rollers to perform micro-pile and loosening processing on the reverse side of the fabric; Stable processing, finally, the gradient structure fabric with tight front side and loose back side is led out by the rear guide roller. The temperature of the hot tension main roller and the hot tension auxiliary roller is adjusted to 160 °, and at the same time, the fabric passes through the liquid tank (surfactant is added in the liquid tank) to realize the hydrophilic finishing of the reverse side of the fabric.

[0040] Experiment: When the fabric absorbs 50% of its own weight, that is, when the moisture regain rate is 50%, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com