Indoor testing apparatus and indoor testing method for simulating pile side post-grouting

A technology for indoor testing and simulating piles, which is applied in the direction of applying stable shear force to test the strength of materials, and can solve the problems of not considering the grouting pressure, grouting amount and load conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

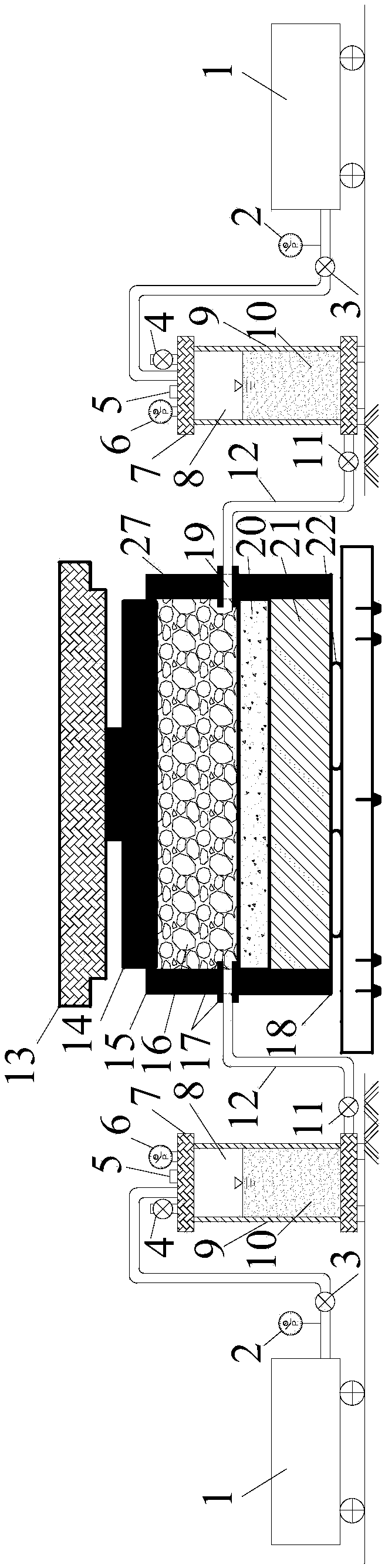

[0083] An indoor test device for simulating post-grouting of pile side, its connection is as follows figure 1 As shown, the device includes a test assembly and a grouting assembly, wherein the grouting assembly includes an air compressor 1 and a slurry tank 8 connected in sequence, and the test assembly mainly includes an interface shear instrument 13, an upper shear box 15 and a lower shear box. Cut box 18.

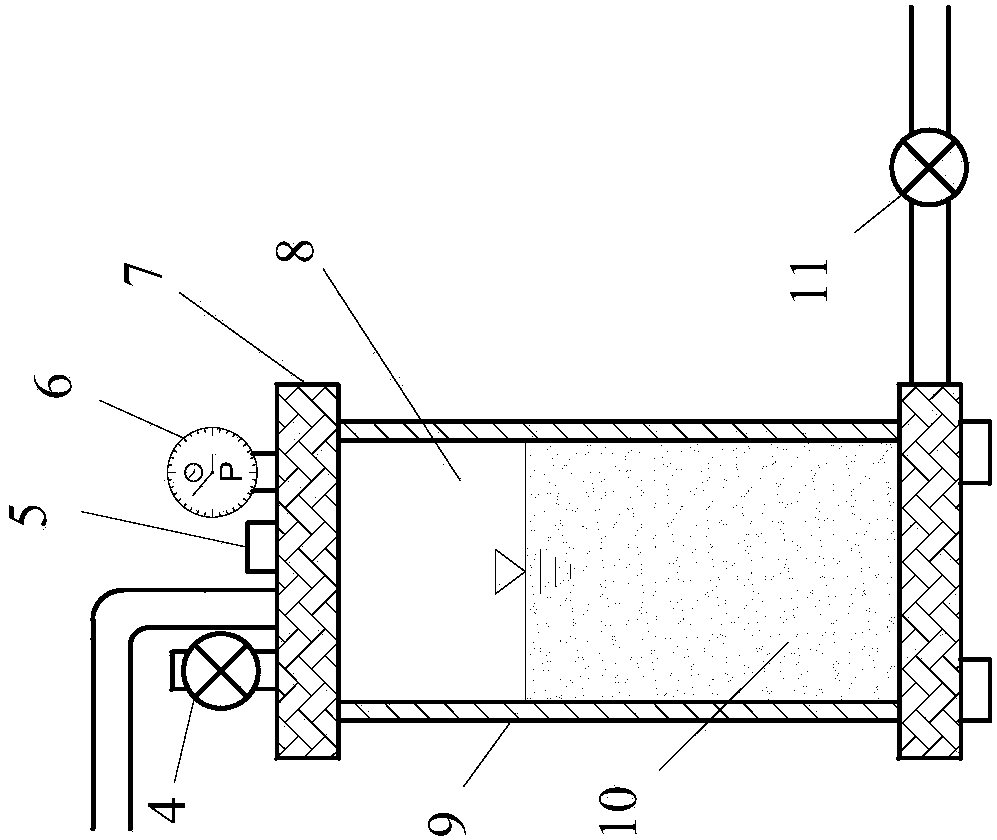

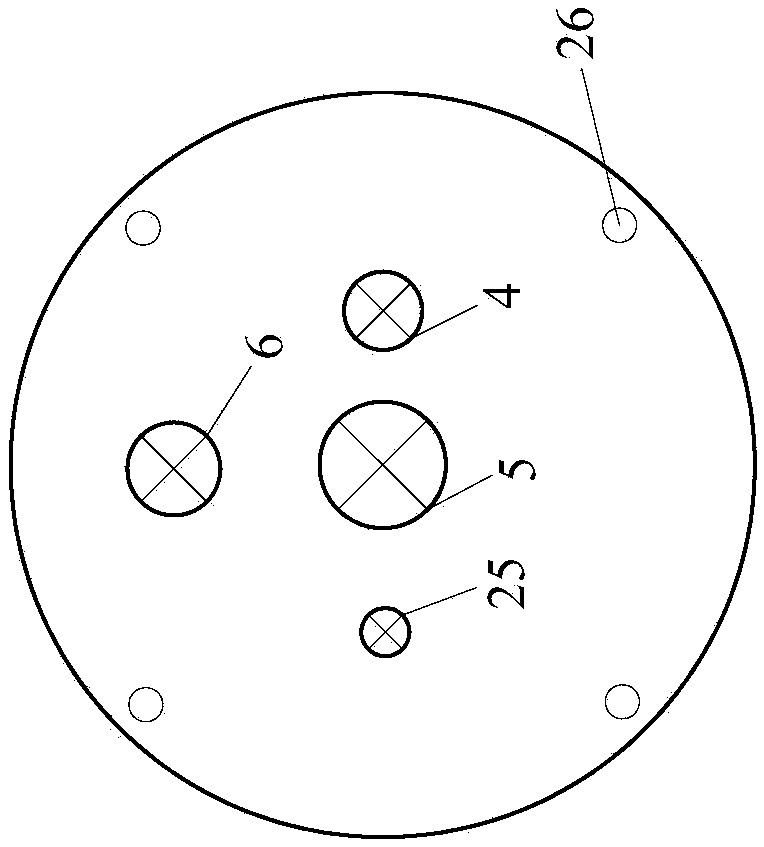

[0084] A pressure gauge 2 and a first pressure regulating valve 3 are arranged on the air compressor 1 . The top of the slurry storage tank 8 is provided with a flange top cover 7, and the side of the bottom plate of the slurry storage tank 8 is provided with a grout inlet pipe 12 with a grout injection valve 11, and is connected to the upper shear of the interface shear instrument 13 through a PC thread straight-through head 17. Cut the grouting hole 19 reserved at the bottom of the front and rear long side plates 27 of the box 15. The interface shear instrument 13 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com