An indoor test method for simulating the upward return of post-grouting grout at the pile tip

A test method and an indoor test technology are applied in the field of indoor test devices for simulating the upward return of grouting slurry at the pile end, which can solve the problems affecting the popularization and application of the post grouting technology at the pile end, the unreasonable size effect, and the study on the characteristics of mechanical properties. not deep enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

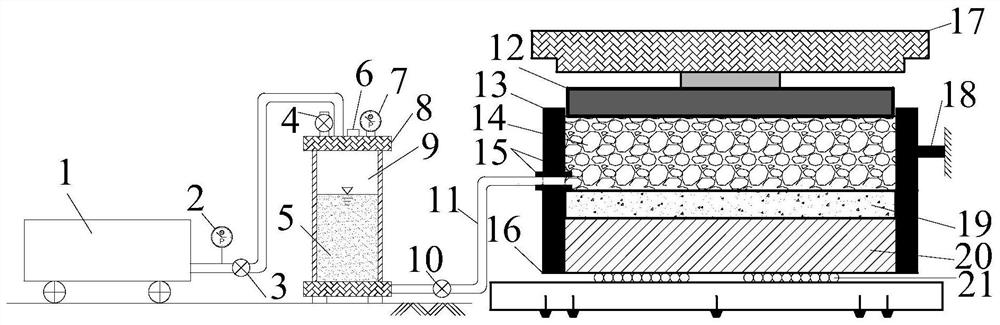

[0073] An indoor test device for simulating the upward return of grouting slurry after the pile tip, its connection structure is as follows figure 1 As shown, the device includes a test assembly and a grouting assembly, wherein the grouting assembly includes an air compressor 1, a slurry storage tank 9, etc., and the test assembly includes an interface shear instrument 17, an upper shear box 13, and a lower shear box 16 etc., the air compressor 1 is provided with a pressure gauge 2 and a first pressure regulating valve 3 . The top of the slurry storage tank 9 is provided with a flange top cover 8, and the top of the flange cover 8 is provided with a pressure relief valve 4, a slurry inlet 6 and a second pressure regulating valve 7, and the side wall of the slurry storage tank 9 is made of transparent plexiglass. , marked with a volume scale, the amount of slurry injection can be observed, the side of the bottom plate of the slurry storage tank 9 is provided with a slurry inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com