Double-*-shaped shaft type force sensor and method thereof

A force sensor and Pozi technology, which is applied in the field of double Pozi axis force sensor, can solve the problem of low sensitivity and achieve the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

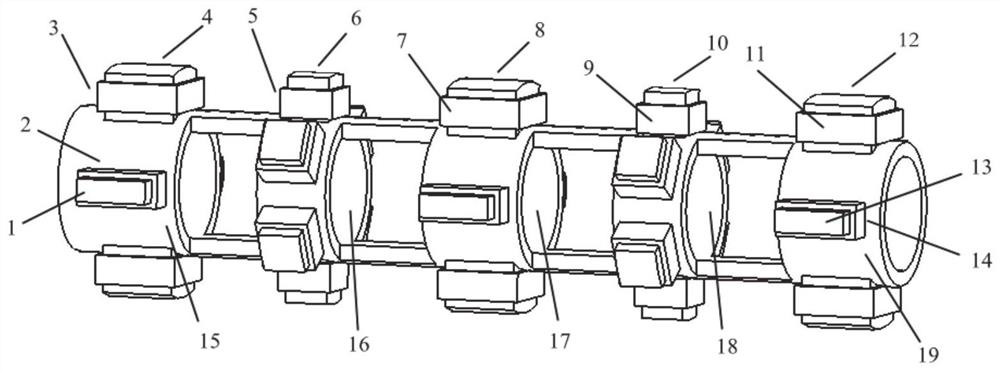

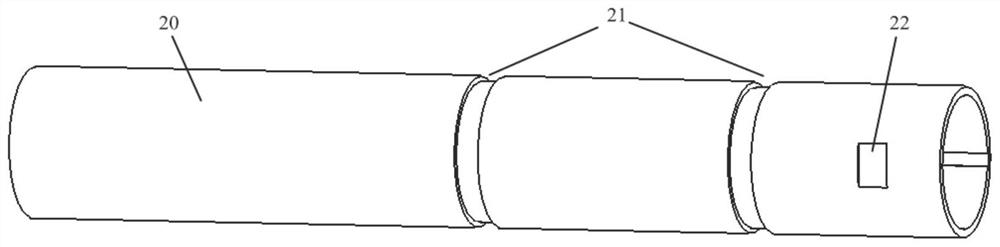

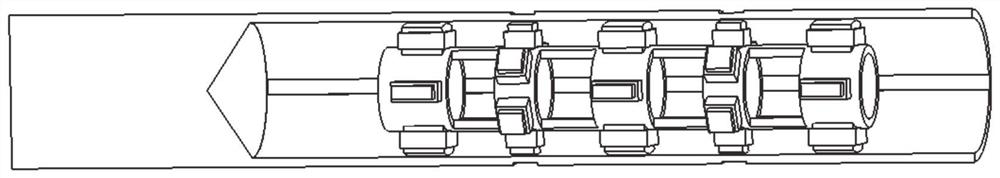

[0034] See attached Figure 1-3 As shown, the novel double Pozir-shaft force sensor includes a load-bearing cylinder 20. The load-bearing cylinder 20 in this embodiment can be processed as a circular tube, or can be formed by drilling holes on the pin shaft. Steps or slot structures 22 can be added for positioning installation.

[0035] Specifically, a first excitation magnetic core 16 and a second excitation magnetic core 18 are installed in the bearing cylinder 20, and the two excitation magnetic cores respectively include a first excitation magnetic pole 6 and a second excitation magnetic pole 10, and the radially symmetrical arrangement of the excitation magnetic poles is " In the shape of "m", the excitation magnetic poles are arranged crosswise on the same cross section of the bearing cylinder 20, and the first excitation magnetic poles 6 and the second excitation magnetic poles 10 are respectively wound with a first excitation coil 5 and a second excitation coil 9, The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com