Method and system for fitting cooling curve

A technology of cooling curves and curves, which is applied in the field of thermal performance testing of electronic devices, can solve problems such as system errors and random noise errors, and achieve the effects of noise reduction, high fitting degree, and simple calculation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] This embodiment discloses a cooling curve fitting method for transient heat test data, which is to use formula (5) to exponentially fit the actually measured cooling curve.

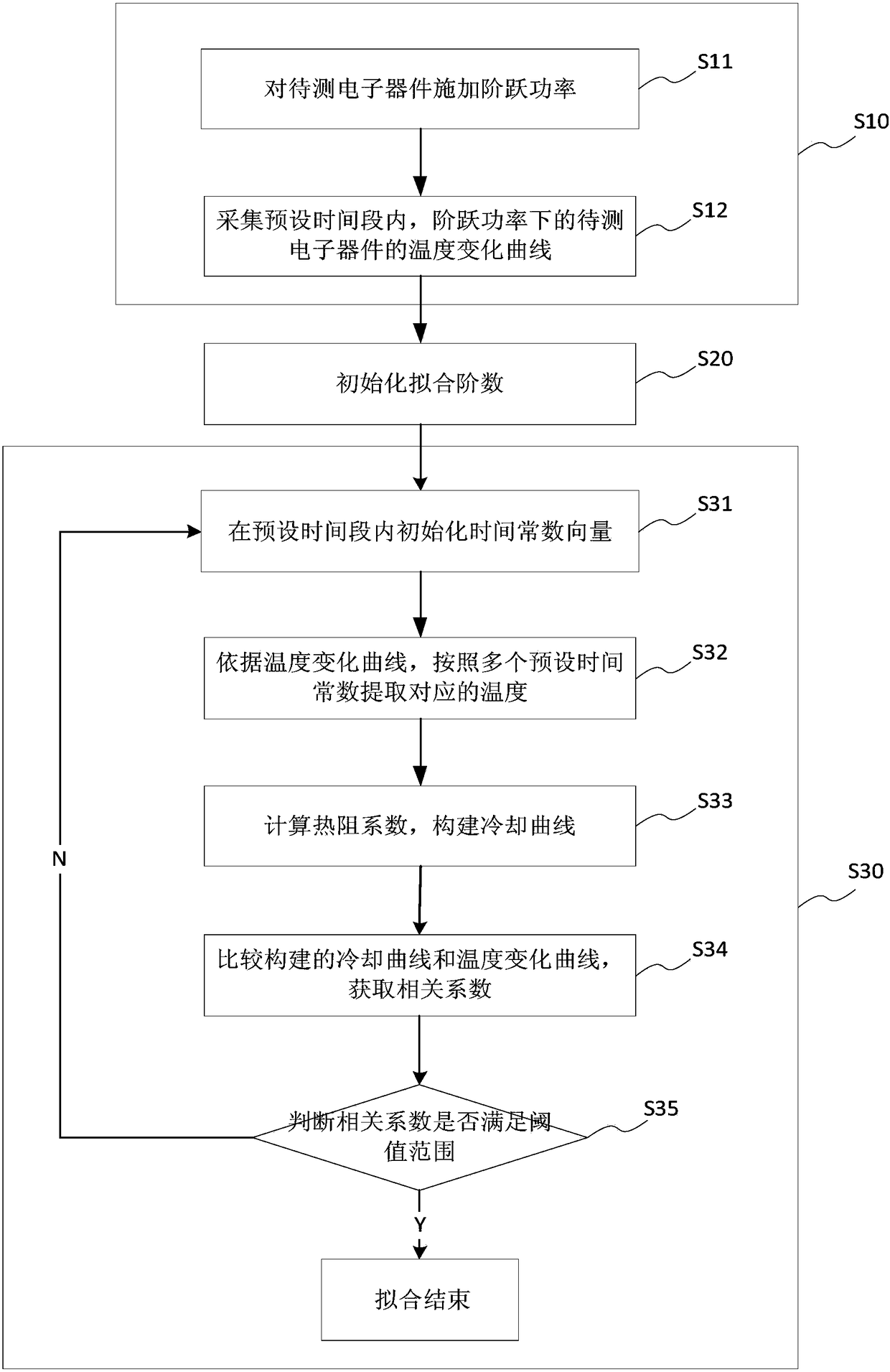

[0060] Such as figure 1 Shown, the cooling method of the cooling curve of the present embodiment comprises:

[0061] Step S10, collecting a temperature change curve of the temperature of the electronic device under test over time within a preset time;

[0062] This embodiment adopts the transient thermal analysis method, then, before collecting the temperature change curve of the electronic device to be tested, it is necessary to apply a step heating power to the electronic device. Therefore, step S10 specifically includes:

[0063] Step S11, applying step power to the electronic device under test;

[0064] Step S12, collecting the temperature change curve of the electronic device under test under step power within a preset time period.

[0065] Wherein, the preset time period is preset accordi...

Embodiment 2

[0090] This embodiment discloses a cooling curve fitting system for transient thermal test data, which uses formula (5) to exponentially fit the actually measured cooling curve.

[0091] Such as Figure 4 As shown, the fitting system of the cooling curve disclosed in this embodiment includes:

[0092] The collection module 410 is used to collect the temperature change curve of the temperature of the electronic device under test over time within a preset time period;

[0093] Wherein, the collection module 410 includes a power application sub-module 411 and a collection sub-module 412 . The power applying sub-module 411 is used to apply step power to the electronic device under test; the collection sub-module 412 is used to collect the temperature change curve of the electronic device under test under step power within a preset time period.

[0094]The initialization module 420 is used to initialize the fitting order and the time constant vector; wherein, the time constant ve...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap