A test device for the characteristics of the polymerization inhibition zone of continuous liquid surface photocuring molding

A technology of light-curing molding and characteristic testing, which is applied in the direction of measuring devices, manufacturing auxiliary devices, permeability/surface area analysis, etc., can solve the problems of lack of research on the characteristics of the polymerization inhibition zone, and achieve the effect of solving oxygen leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

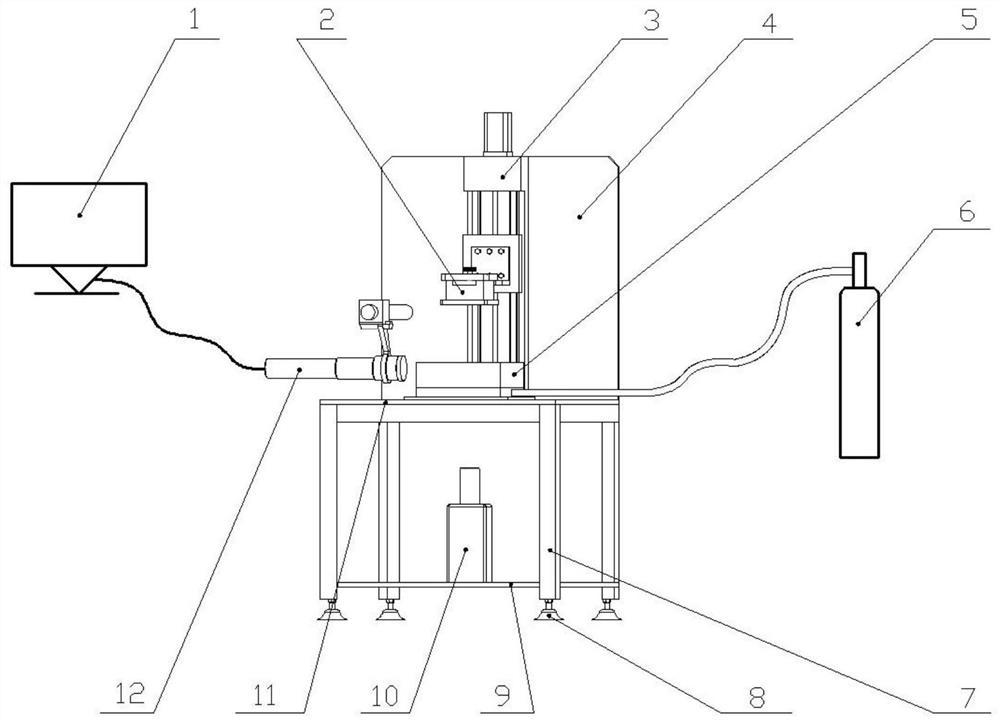

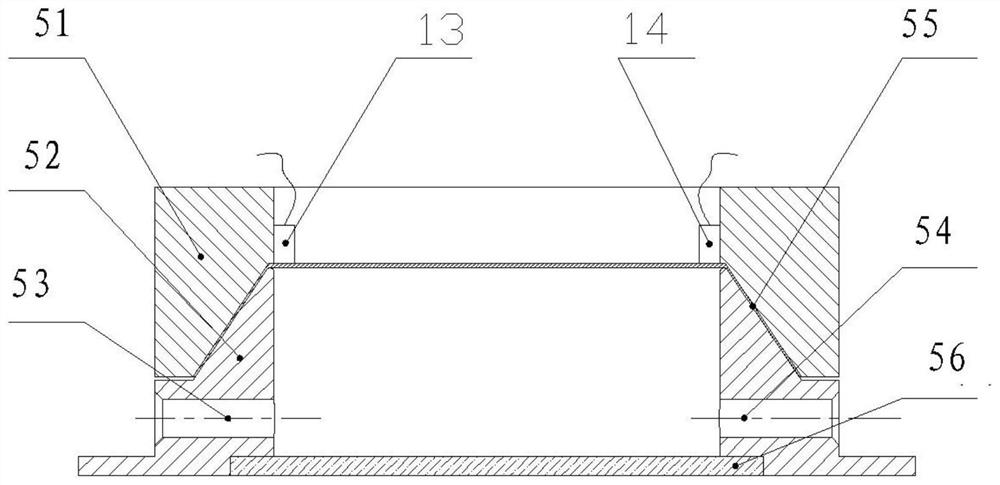

[0021] Such as figure 1 As shown, a continuous liquid surface light-curing forming polymerization inhibition zone characteristic test device is characterized in that it includes a PC machine 1, a carrier plate 2, a feeding device 3, a side support plate 4, a resin tank 5, and an oxygen supply device 6 , pedestal 7, leveling device 8, base 9, curing light source 10, upper bracket 11, video microscope observer 12 in the polymerization prevention zone; the PC 1 is connected with the video microscope microscope 12 in the polymerization prevention zone, Polymerization zone video microscopic observer 12 is fixed on the side support plate for real-time observation of changes in the thickness of the polycondensation zone, the resin tank 5 is connected to the oxygen supply d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com