Semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of photoresist load effect, reduce the etching precision of device-intensive areas, etc., and achieve the effect of avoiding load effect

Active Publication Date: 2018-10-02

SEMICON MFG INT (SHANGHAI) CORP +1

View PDF2 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] However, there are certain problems in the existing embedded silicon germanium process

Due to the different arrangement densities of devices on the same wafer, the source/drain groove densities of the

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

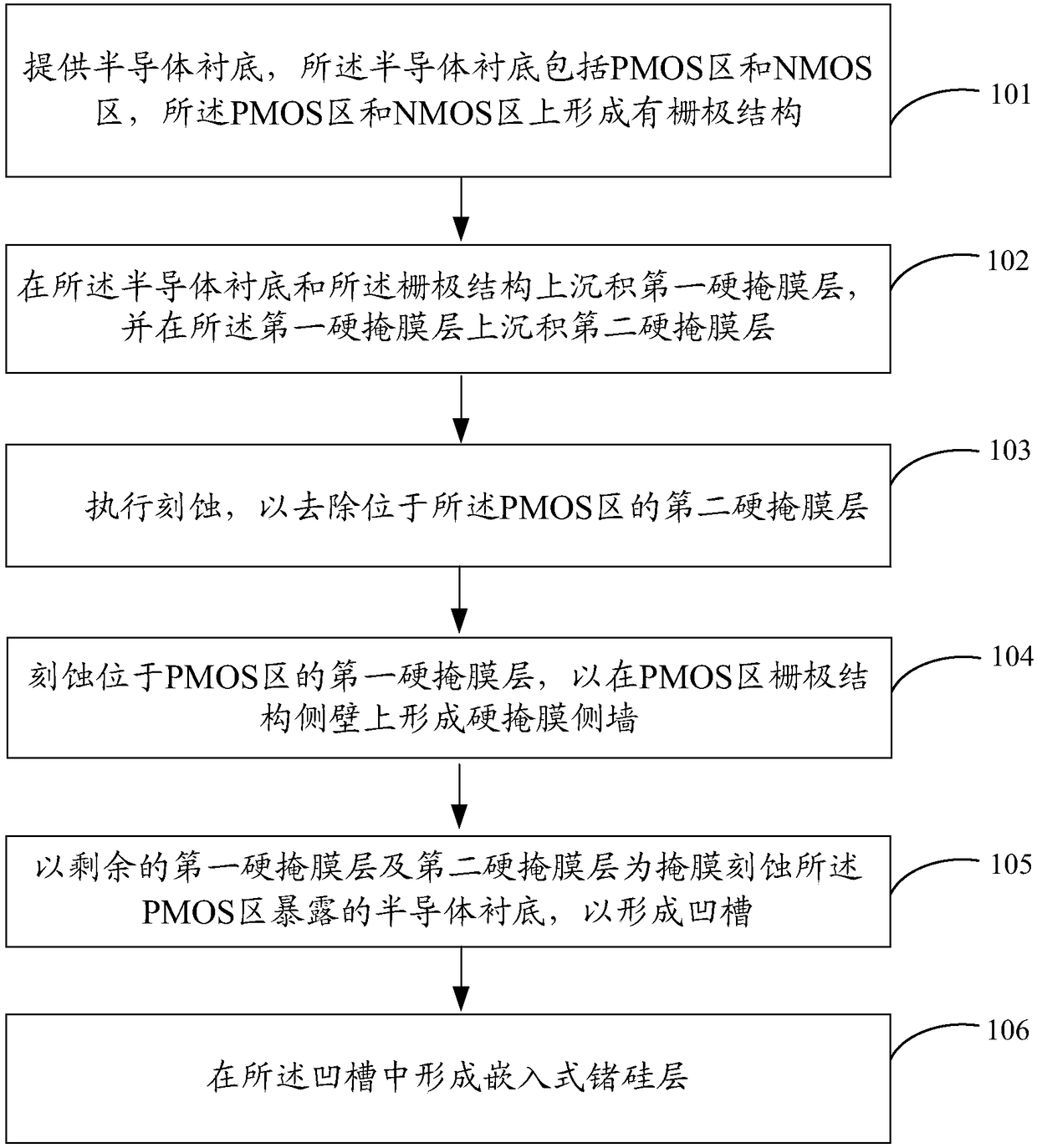

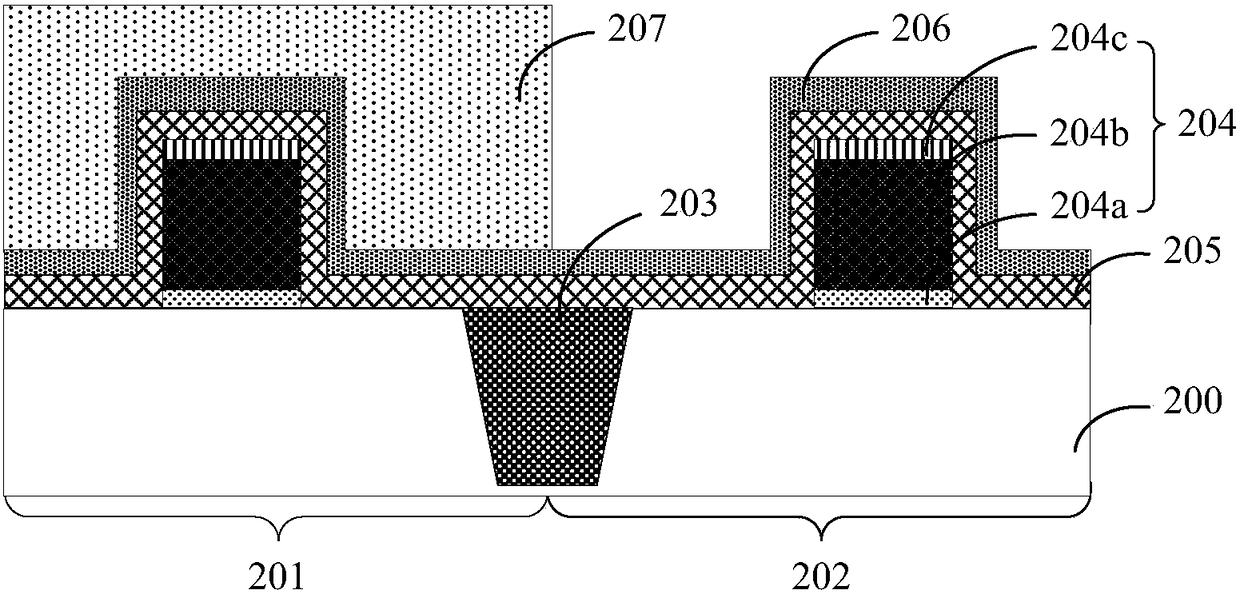

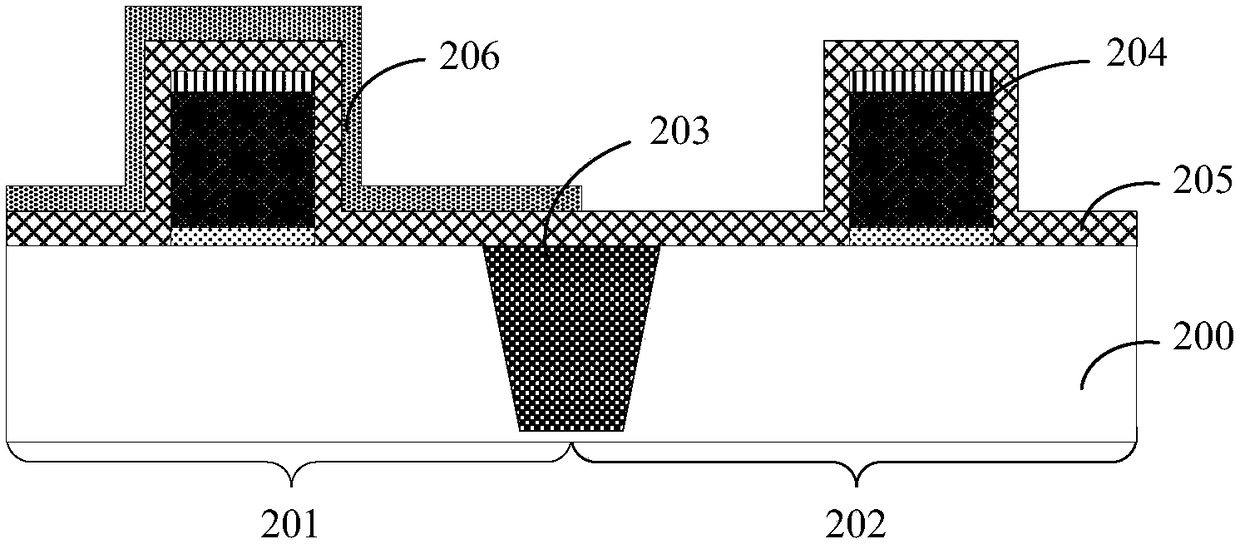

The present invention provides a semiconductor device and a manufacturing method thereof. The manufacturing method includes the following steps that: a semiconductor substrate is provided, wherein thesemiconductor substrate includes a PMOS region and an NMOS region, gate structures being formed on the PMOS region and the NMOS region; a first hard mask layer is deposited on the semiconductor substrate and the gate structures, and a second hard mask layer is deposited on the first hard mask layer; etching is performed so as to remove the second hard mask layer on the PMOS region; the first hardmask layer on the PMOS region is etched, so that a hard mask sidewall can be formed on the sidewall of the gate structure at the PMOS region; with the remaining first hard mask layer and second hardmask layer adopted as a mask, the semiconductor substrate exposed at the PMOS region is etched, so that a groove can be formed; and an embedded germanium silicon layer is formed in the groove. With the manufacturing method of the invention adopted, the load effect of photoresist can be avoided.

Description

Technical field [0001] The invention relates to a semiconductor manufacturing process, in particular to a semiconductor device and a manufacturing method thereof. Background technique [0002] With the continuous development of integrated circuit technology, more devices will be integrated on the chip, and the chip will also adopt faster speeds. With the advancement of these requirements, the geometric dimensions of devices will continue to shrink, and new materials, new technologies and new manufacturing processes will continue to be used in the manufacturing process of chips. At present, the preparation of semiconductor devices has developed to the nanometer level, and the preparation process of conventional devices has gradually matured. [0003] Conventionally, PMOS and NMOS are processed separately in CMOS device manufacturing technology. For example, compressive stress materials are used in the manufacturing method of PMOS devices, and tensile stress materials are used in NM...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01L27/092H01L21/8238

CPCH01L27/0928H01L21/8238

Inventor 韩秋华吴端毅

Owner SEMICON MFG INT (SHANGHAI) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com