Method for disconnecting lead by live-line work robot

A live work and robot technology, applied in the direction of overhead line/cable equipment, etc., can solve the problems of designing fixtures and wire clips, complicated operation steps, easy mutual interference, etc., to avoid falling off, simplify operation steps, and improve power supply reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

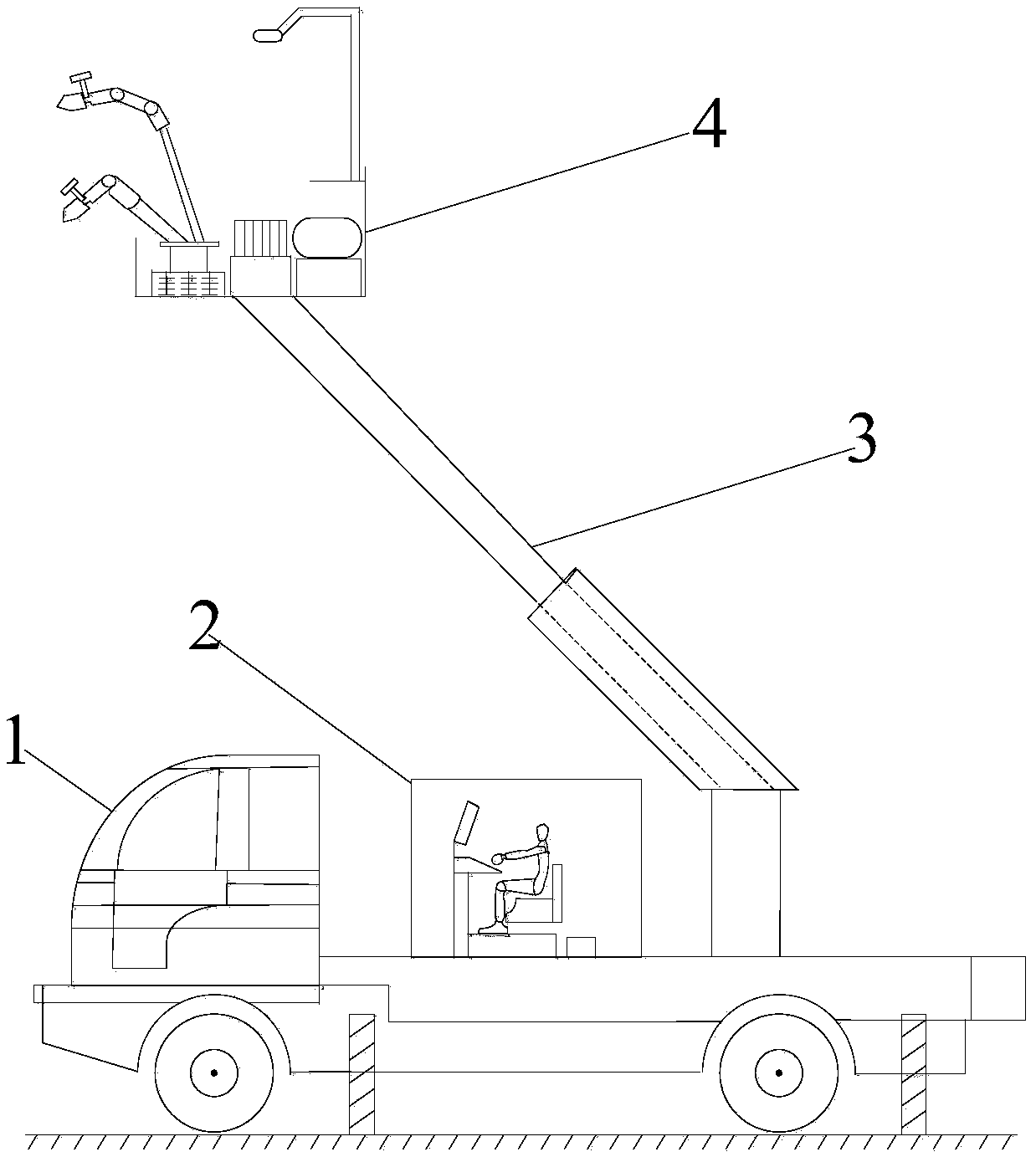

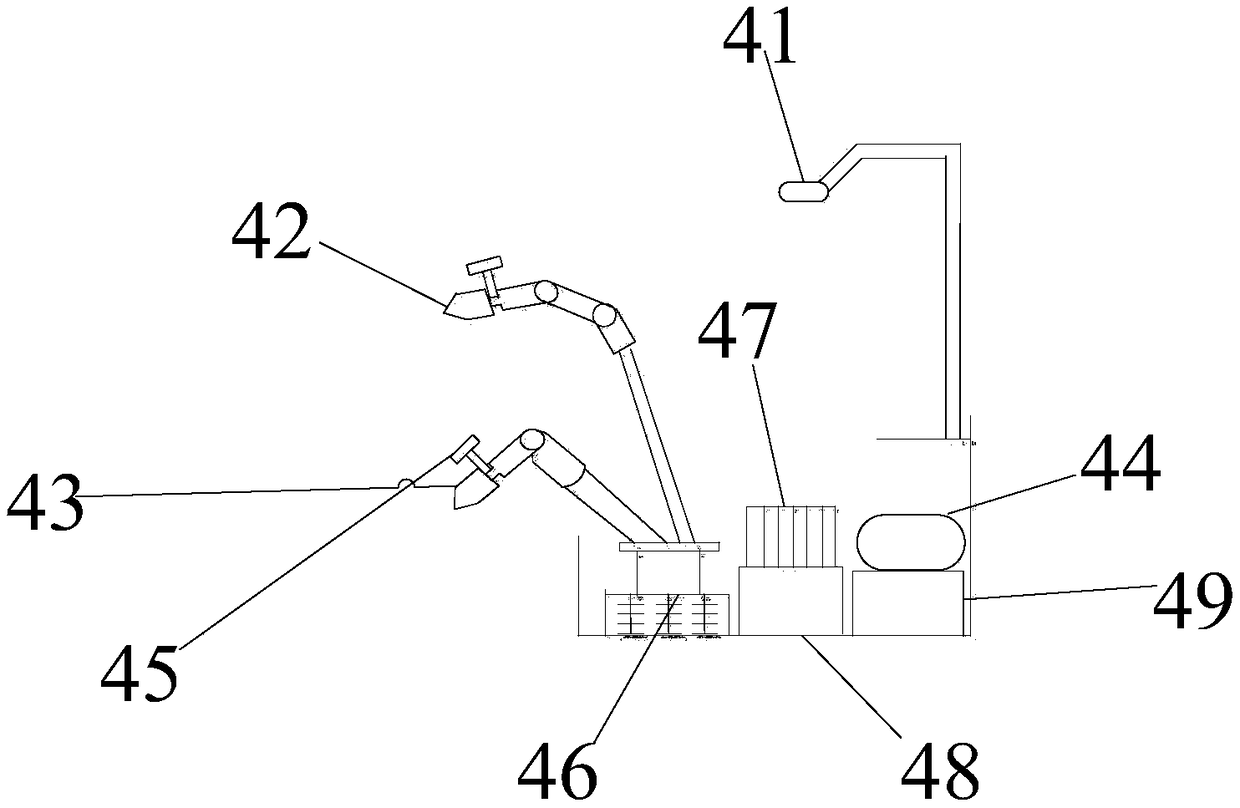

[0053] As an implementation, combining Figure 9 , in the working environment, high-voltage wires 104 are erected between adjacent towers 101 , and crossarms 102 are installed on the towers 101 for fixing and installing drop-out fuses 103 . The upper end of the drop-out fuse 103 is drawn out with a lead wire 105 , and the connection between the drop-out fuse 103 and the high-voltage wire 104 is realized through a special clamp 106 .

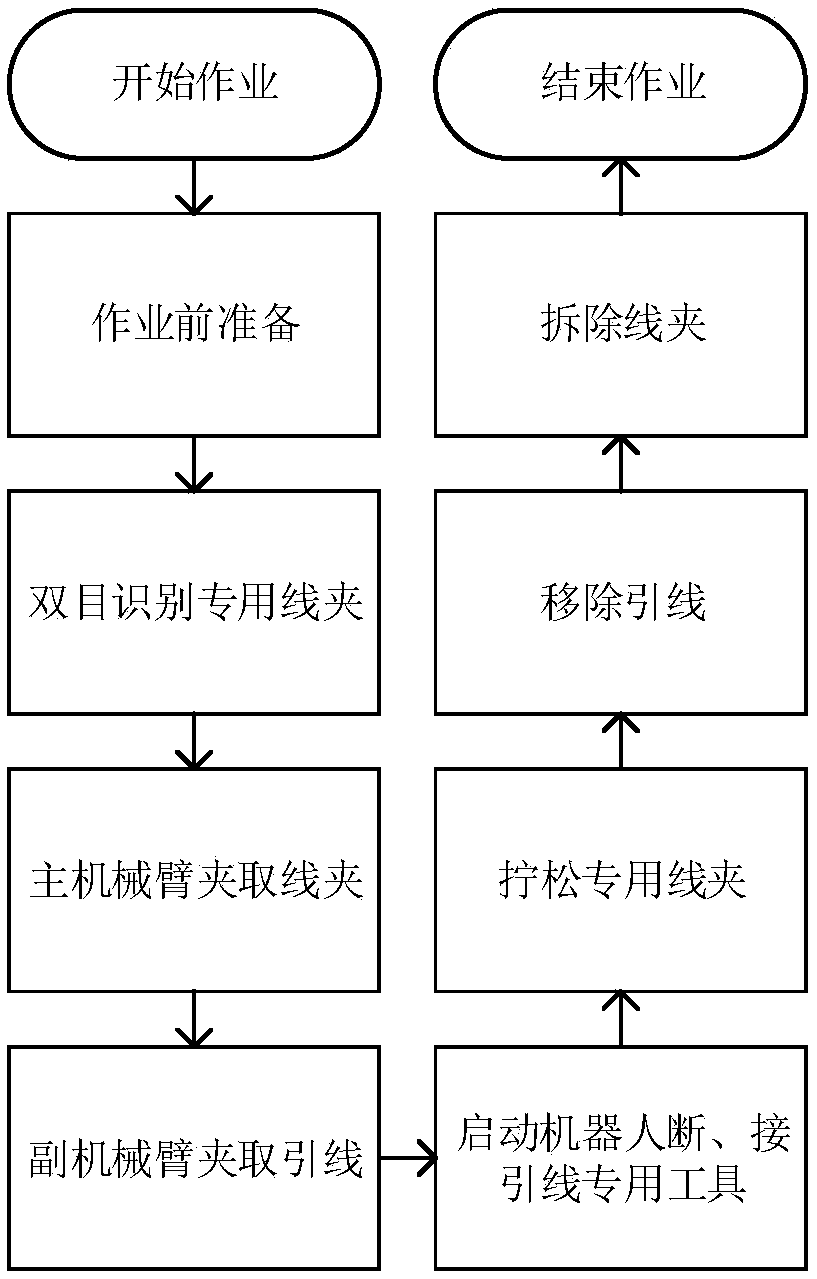

[0054] The lead wire breaking method of the live working robot of the present invention comprises the following steps:

[0055] 1. The staff prepares for the work before the live working robot breaks the lead wire 105, checks the weather conditions, checks the wire number, arranges the site, and performs installation, inspection and testing of the end tools of the robot:

[0056] 1.1 Check the weather conditions, surrounding environment, line installation and safety measures.

[0057] 1.2 Arranging the site: Set up safety guardrails, operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com